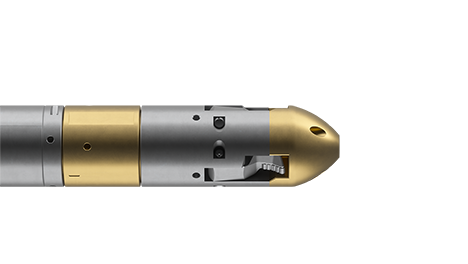

A gap in recovery from subsea fields

Examples from certain areas show that there exists a gap of 30-40% in recovery from subsea fields compared to similar platform-based fields.

The discrepancy to a large degree can be attributed to lack of regular downhole production maintenance - basically lack of interventions. Welltec® is a key provider of the technology required to boost subsea recovery.