Eliminate methane emissions – today

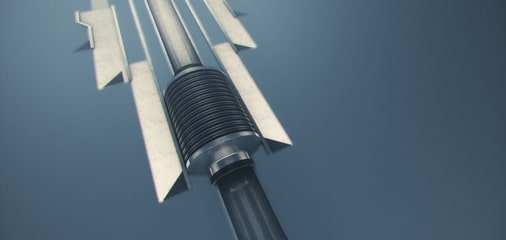

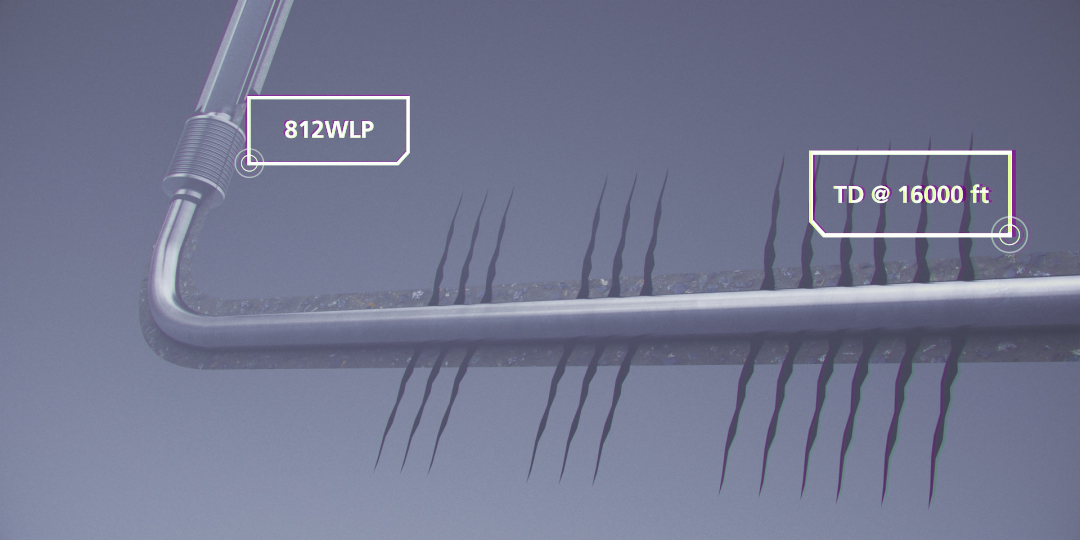

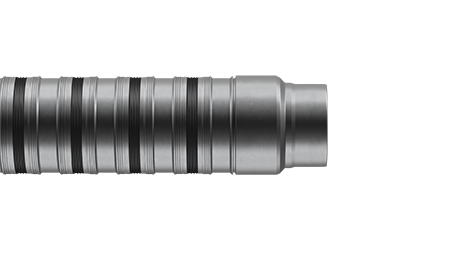

Methane emissions prevention is synonymous with reliable well integrity, and the elimination of Sustained Casing Pressure (SCP). Welltec® has installed patented completion products in more than 1,000 wells across the globe, establishing an impeccable track record in helping its partners address these important environmental challenges.