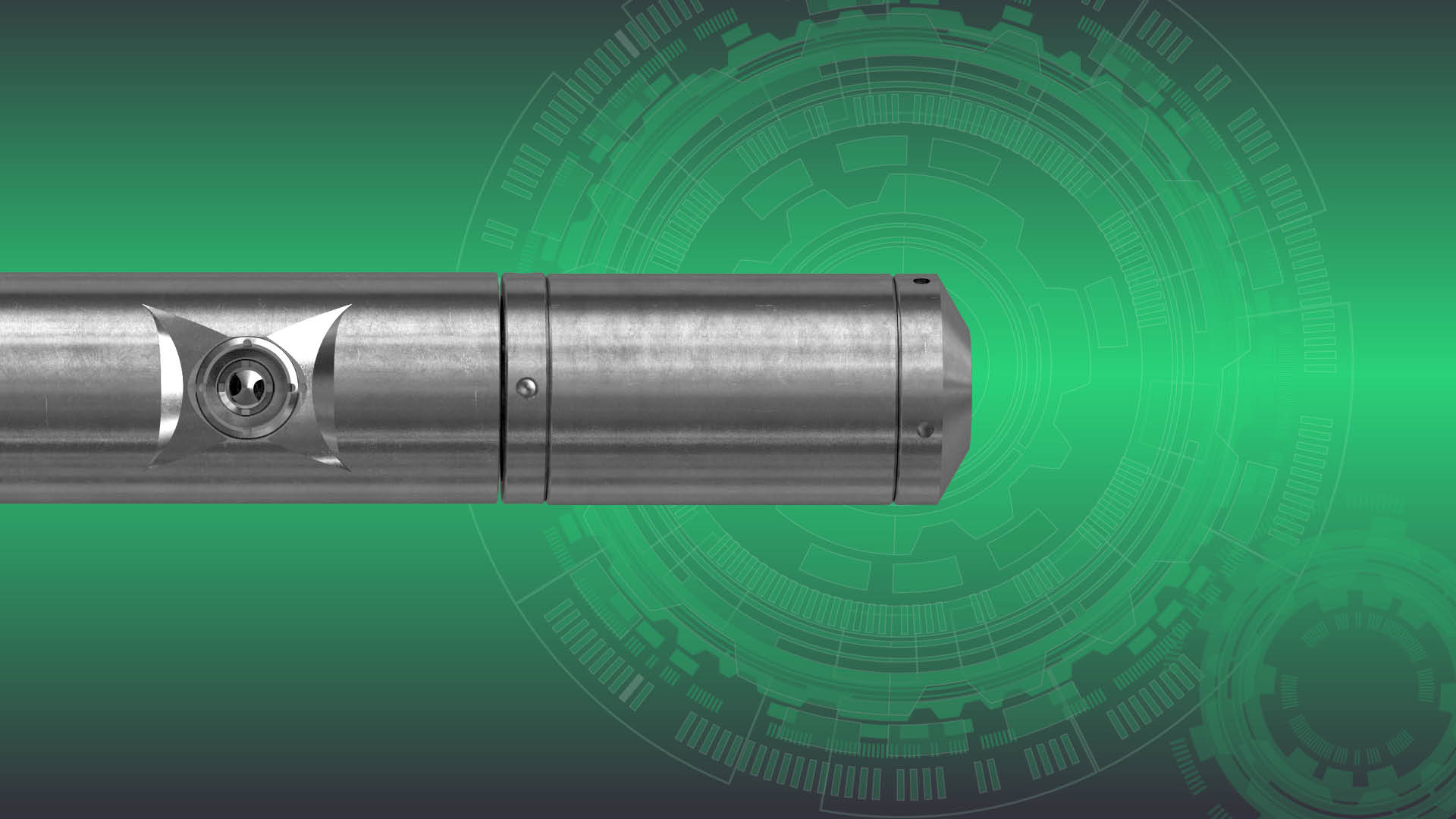

Welltec® Puncher

Non-explosive method for equalizing pressures between tubular strings

Introduction

-

ApplicationsNon-explosive punching for pressure release

-

ChallengePlug and abandonmentDownhole hardware

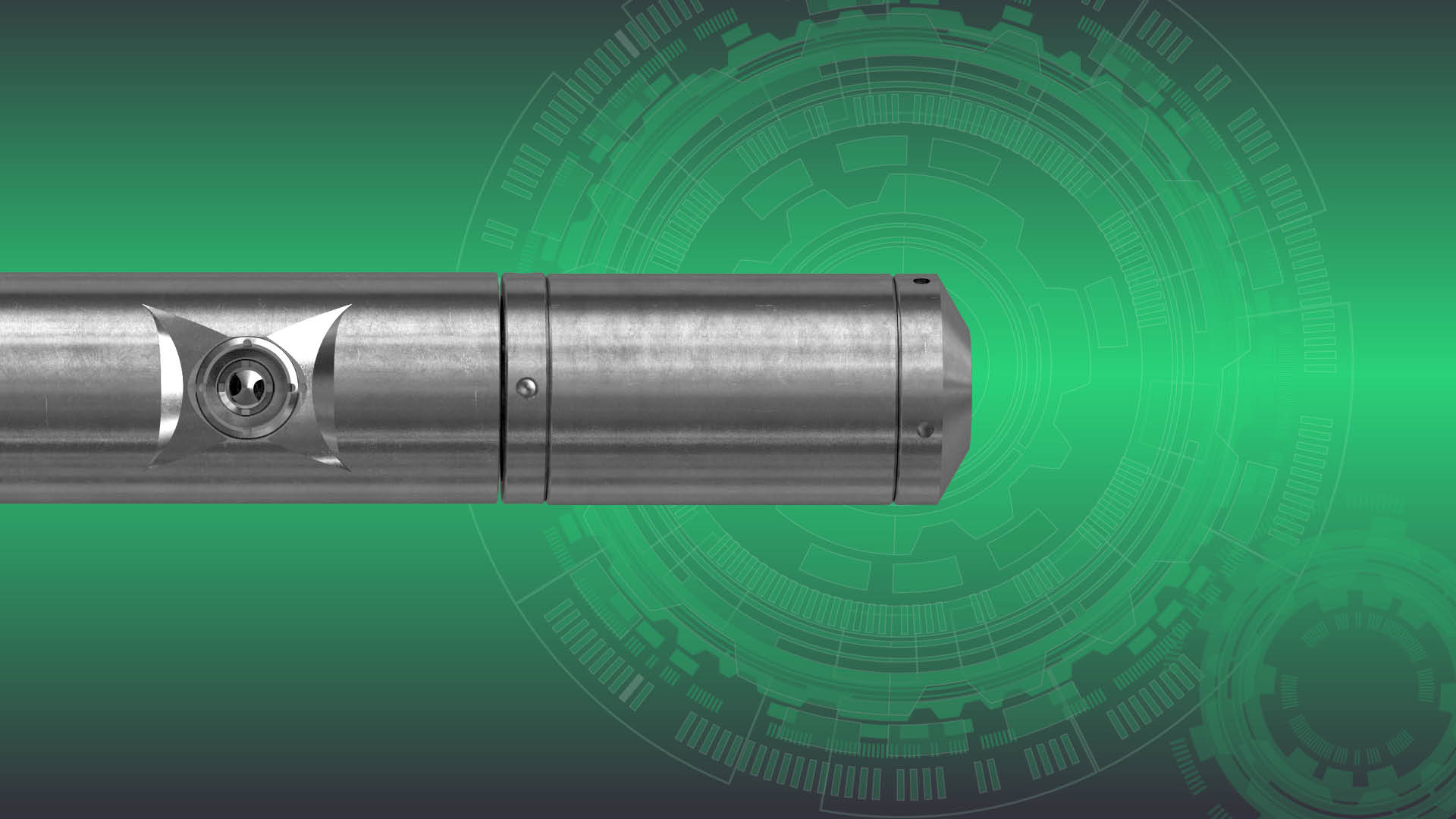

Welltec Puncher provides an efficient, e-line conveyed, non-explosive method for equalizing pressures between tubular strings.

Available with an ultra-slim outer diameter of just 2.125”, its innovative design is ideal for extended reach and going beyond narrow ID restrictions.

Welltec Puncher 218 truly stands apart from anything else on the market, as the slimmest non-explosive puncher capable of creating multiple perforations on a single run.

Case highlight

During plug and abandonment (P&A) preparation offshore Denmark, TotalEnergies wanted to circulate trapped gas from a well by creating multiple perforations in the 4-1/2” casing (28Cr alloy)...

Overview

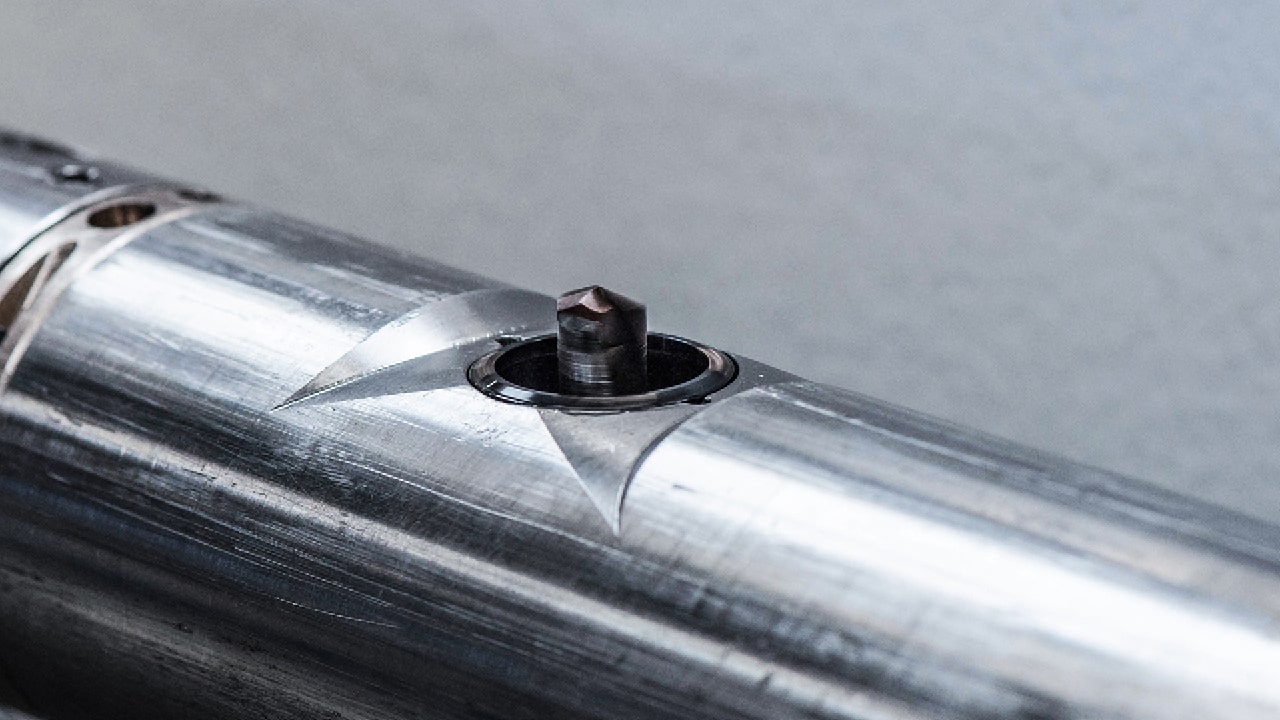

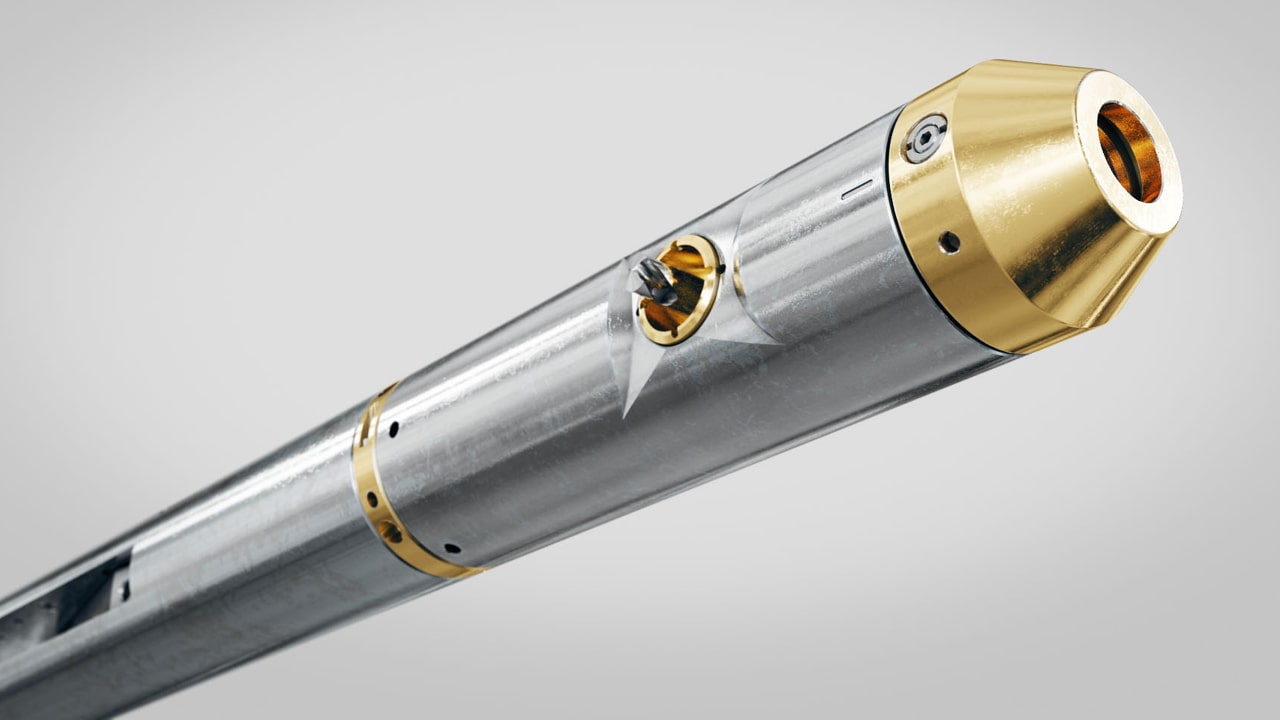

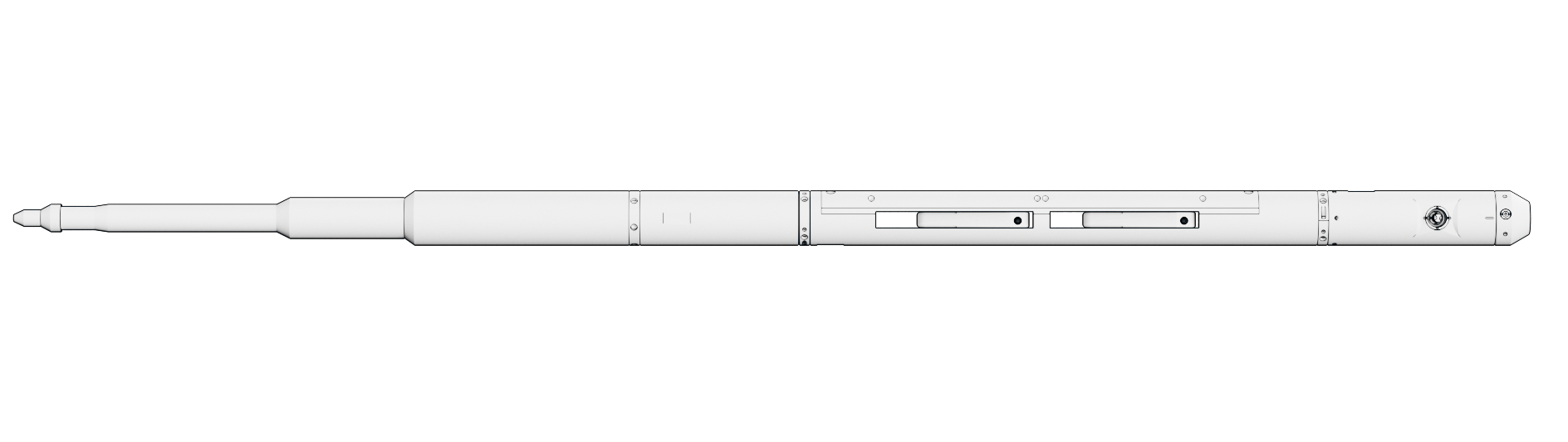

The Welltec Puncher provides an efficient, e-line conveyed, non explosive method for equalizing pressures between tubular strings. Its innovative design quickly creates a controlled diameter hole in the tubular at the target depth for pipe recovery or completion removal without the use of explosives.

Utilizing a fast, drilling technique, the Welltec Puncher produces a precise, uniform hole. The puncher can be run slick to any depth in the well or equipped with a ‘no-go’ for a hole punch at an exact depth. Multiple holes can be drilled in a single descent and it can be deployed independently or with other tools. It can be combined with the Well Tractor® for punching in highly deviated or horizontal wells.

Applications

- Pressure equalization

- Heavy fluids injection

- Production inflow control

- Injection flow control

- Production increase

Features

- Through tubing hole punching

- Through wired

- Modular and configurable

- Compatible with all service providers

- NACE compliant

- Surface readout and control

Benefits

- No explosives

- Multiple punches in the same run

- No perforation burr

- Combinable with other Welltec services

- Rigless punch for batch work

- Accurate depth control

Specification*

| Lenght | 20,5 ft 21 ft |

|---|---|

| Running OD nominal | 2 1/8" 3 1/8" |

| Weight in air | 235 lbs 385 lbs |

| Minimum completion ID | 2.4" 3.4" |

| Maximum pipe thickness | 0.65" 1" |

| Maximum pipe ID | 4.53" 9.8" |

| Punch hole diameter | 0.5" 1" |

| Punch extension | 0.67" 1" |

| Maximum well pressure | 20,000 psi 25,000 psi |

| Tensile strength | 30,000 lbs 42,000 lbs |

| Compressive strength | 36,000 lbs 50,000 lbs |

| Maximum well temperature | 302 F |

| * | Dependent upon configuration |

Introducing the new Welltec Puncher 218

- Reliable – Robust – Strong – Failsafe – Agile

- Thru-tubing capabilities – 5½” tubing

- Multiple holes with controllable drilling depth

- Low maintenance cost and time (Tool availability)

- World-class user interface – ease of use and sleek design