Increased net present value

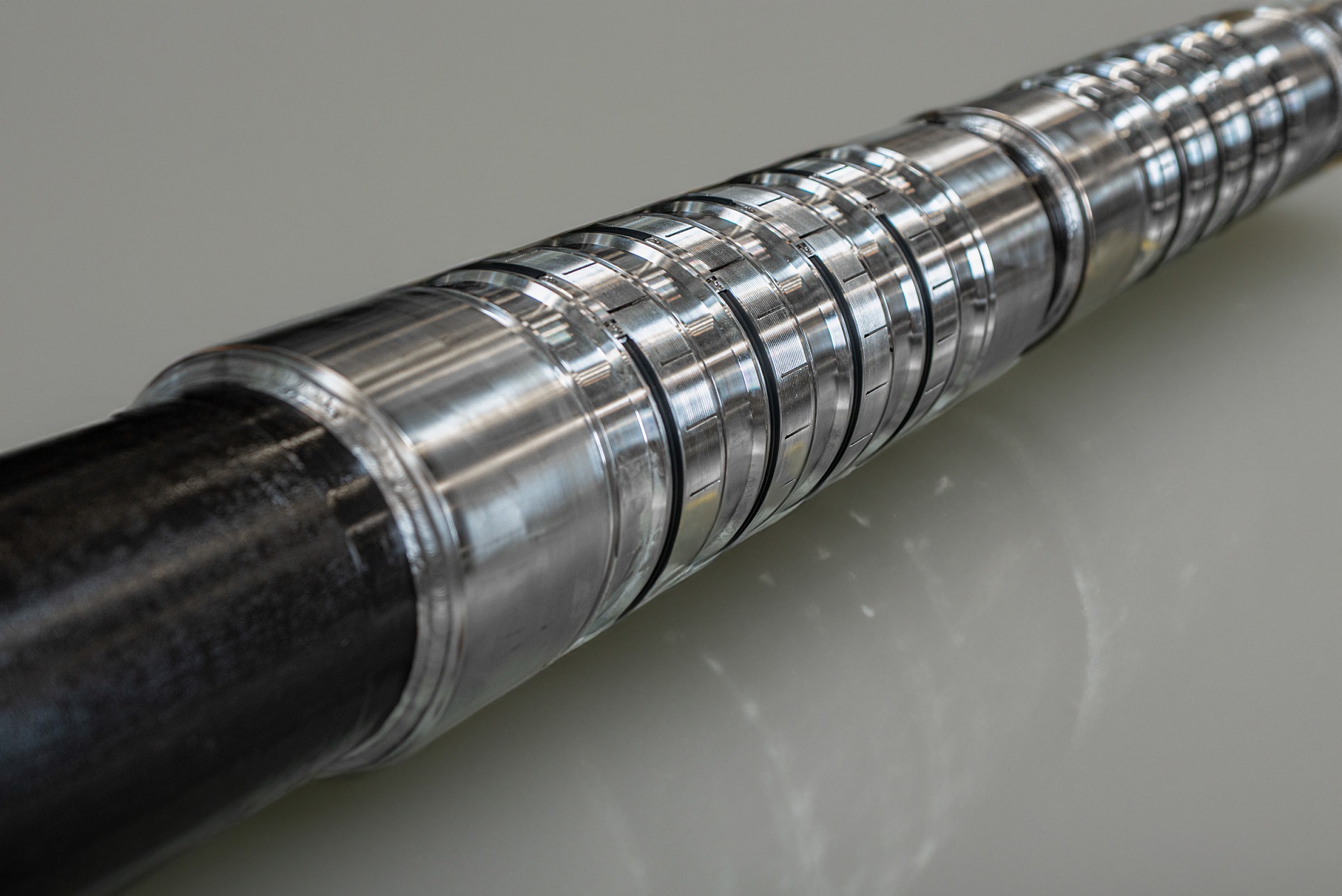

Designing a lower completion for reservoir sections with a high degree of inclination can be challenging as it requires reliable isolation between the lower completion and open hole. Liner hangers and liner top packers are critical in maintaining well integrity and ensuring the success of drilling and completion operations.