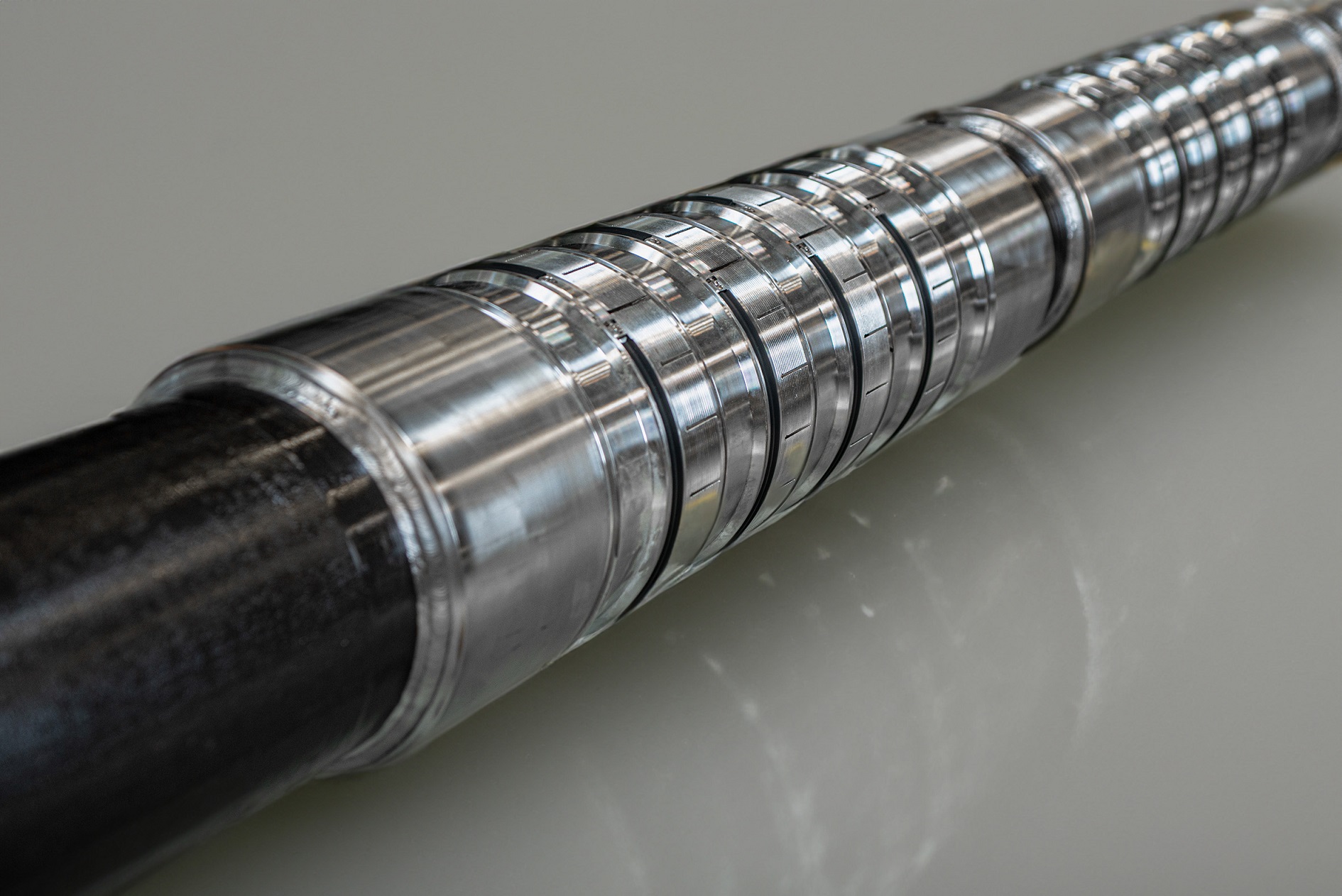

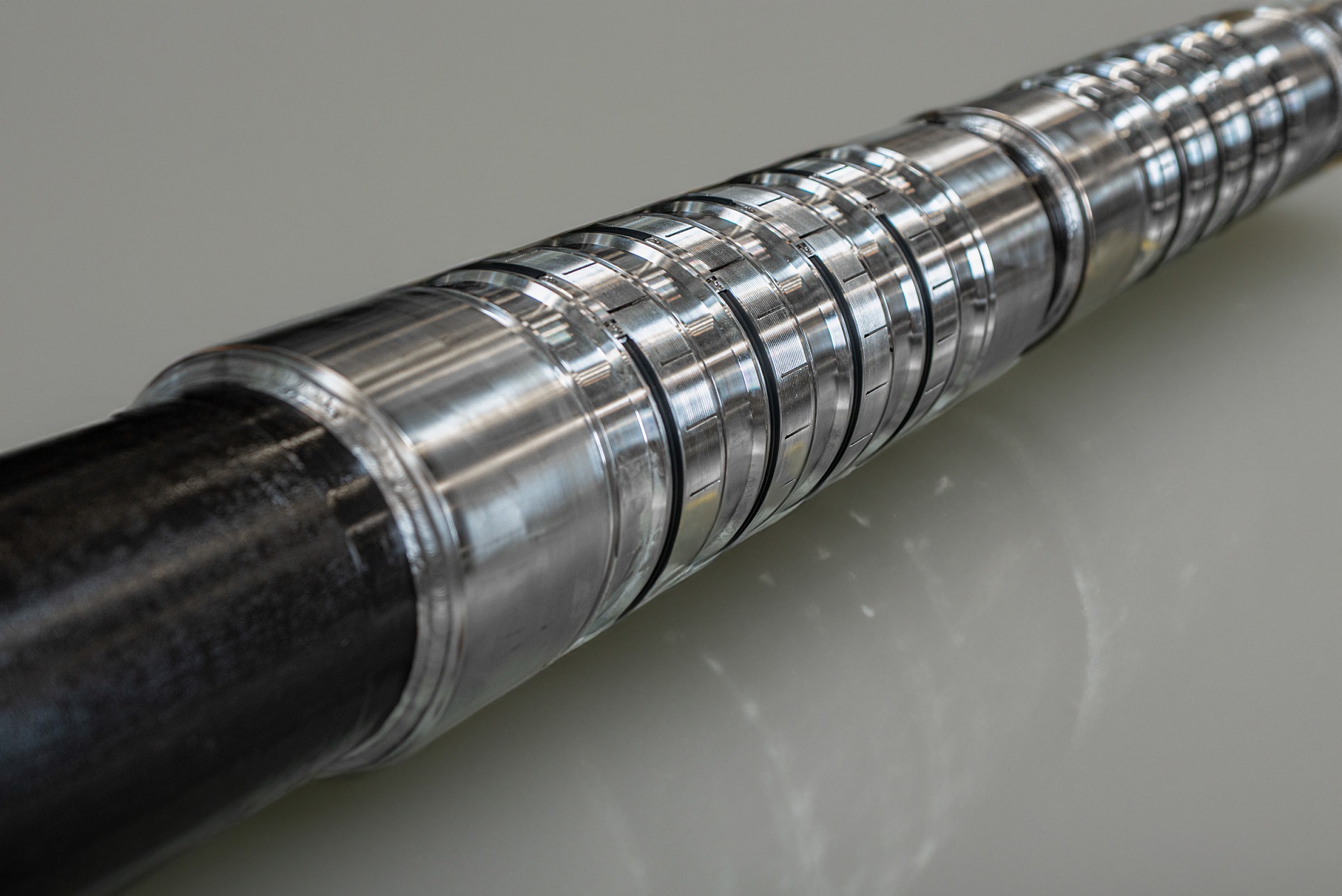

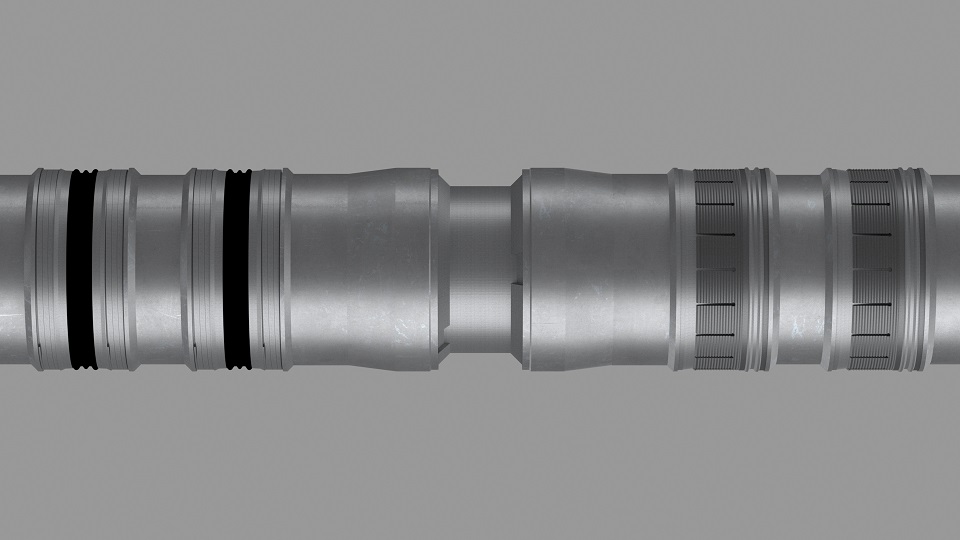

Anchoring capability

In addition to the sealing function, inner-string packers might incorporate opposing slips which act as an anchor. The slips are designed to engage with the inner surface of the host casing, providing mechanical support and preventing movement of the base pipe. This anchoring capability is vital in applications where axial or rotational forces may be encountered, such as during well stimulation or production operations.