Zonal isolation and control

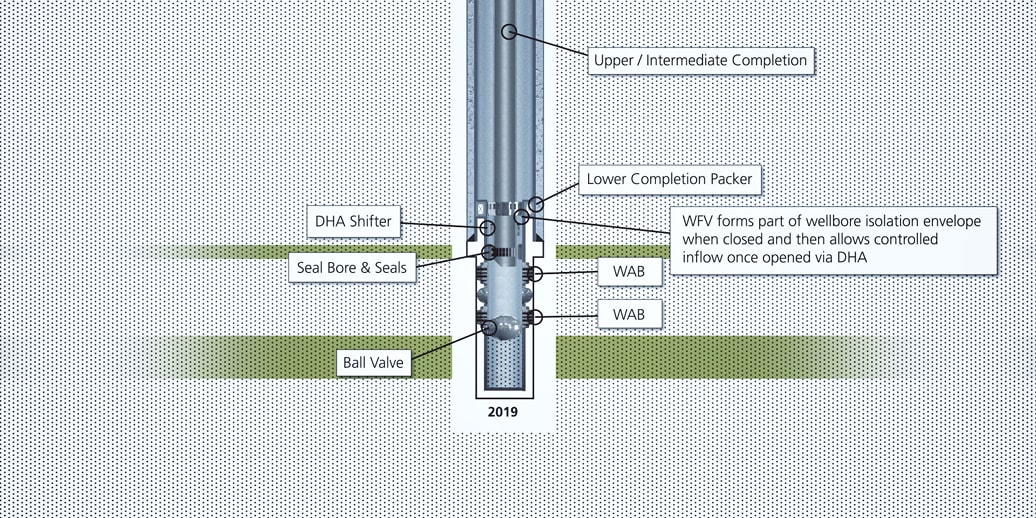

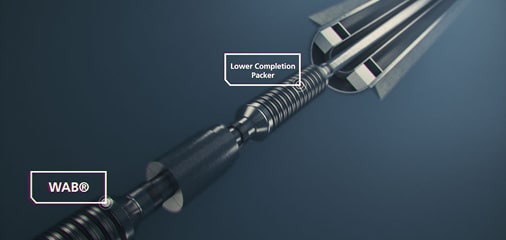

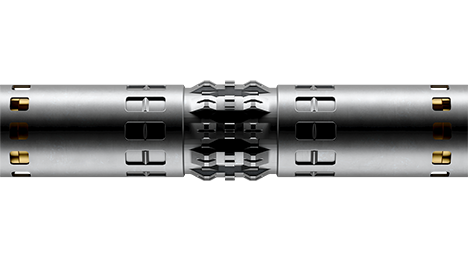

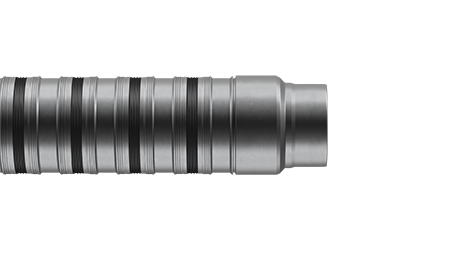

AWA is comprised of our industry proven Welltec® Annular Barrier (WAB)® for zonal isolation and Welltec Flow Valve (WFV™) with Dual Position (DP) for inflow control. Ran in combination across an open hole reservoir section, this system facilitates full bore, cementless, zonal isolation and control.

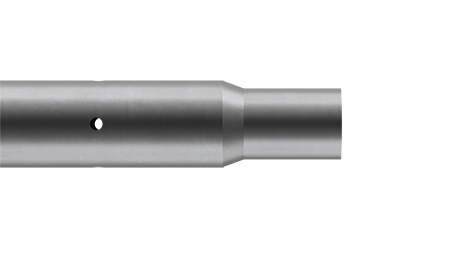

The addition of Welltec's Downhole Actuator (DHA) onto the upper Intelligent Completion (IC) extended inner string engages with and mechanically shifts open the WFV-DP just prior to landing off the upper completion, providing flow access to the previously isolated zones. Welltec AWA enables safe deployment of intelligent completions in wells with losses.