WAB® overcomes depleted zone to deliver a primary well barrier

- Well type Oil producer

- Total depth 12,600 ft

- Challenge Methane emissions prevention

- Result Sustained Casing Pressure (SCP) eliminated

Background

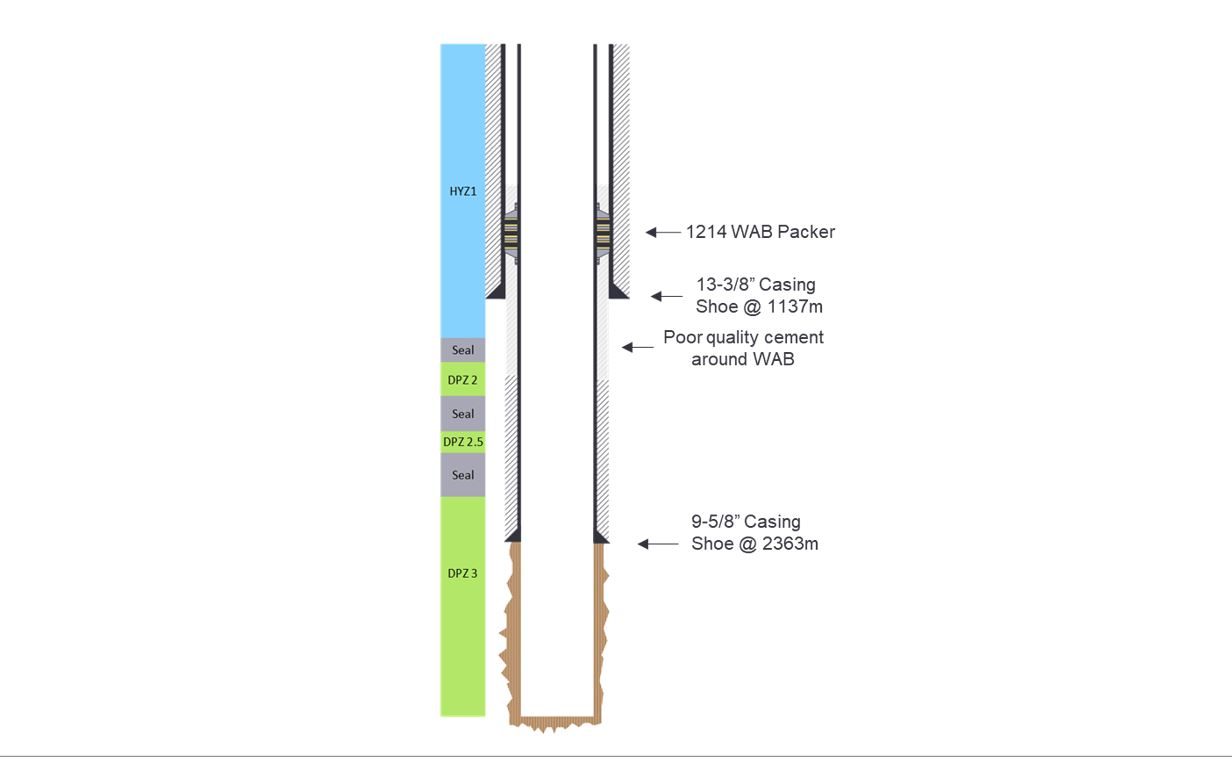

A client operating in the North Sea had experienced issues of Sustained Casing Pressure (SCP) during the construction of new wells, specifically B annulus SCP. The cause of this issue was suspected to be a combination of losses through channeling and micro annulus in cement. The micro annulus appears when circulating to a lighter brine when running the completion.

To address the SCP issue, the client considered tie-back, second-stage cementing, and swell packers. The client attempted setting swell packers in the 13-3/8” casing as well as secondary cement options, but both solutions failed to prevent SCP.

The client required a completion solution to prevent constant pressure build-up in the B annulus, and therefore prevent SCP from occurring.

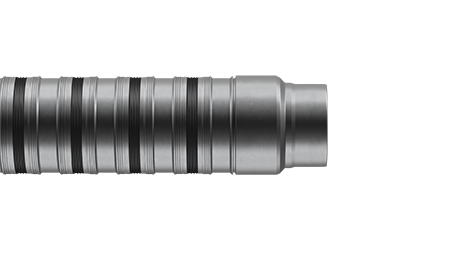

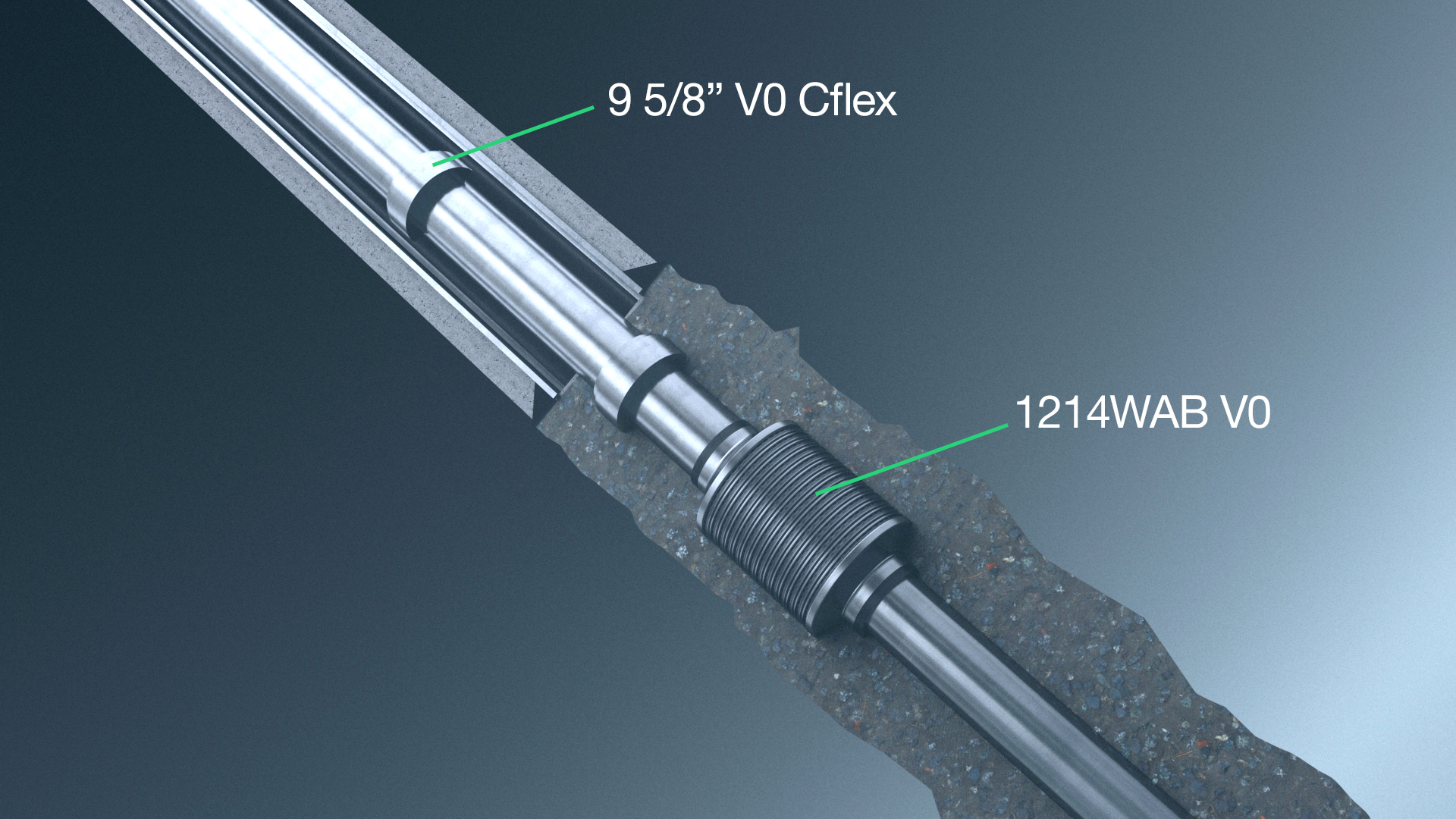

Welltec® proposed a solution using metal expandable packer technology, a 1214 Welltec Annular Barrier (1214WAB®), on the 9-5/8” casing string with the 1214WAB set just above the 13-3/8” casing shoe. Secondary cementing could then be placed above the packer.

Operation

Welltec designed and qualified a metal expandable packer solution to meet the client's stringent criteria.

At the wellsite, Welltec deployed the 1214 WAB in the 9-5/8” casing string and positioned it above the 13-3/8” casing shoe. The primary cement job anchored the 9-5/8” casing string in place, and a secondary cement job was completed with the top of the cement placed above the WAB.

The 1214 WAB was set, and the cement was allowed to harden before pressure testing the casing string. No pressure build-up was observed in the annulus. The drilling operations continued, and the well was successfully completed without the occurrence of SCP.

Achievements

The client was impressed with Welltec’s solution and was grateful for the delivery of a successful operation. The 1214 WAB enabled the client to complete the well without SCP occurring, potentially saving millions (USD) from would be attempts to resolve SCP or carry out a workover. The client now has a solution to prevent SCP from occurring during construction and completion of new wells.

This solution supplements the cement as a well barrier, and the WAB’s fast, surface-controlled expansion saves rig time. The metal expandable packer technology provides annular isolation qualified to V0 for the life of the well.

To date, the client has not recorded B annulus SCP and is now considering standardizing metal expandable packers in their future well construction designs.