Improving Well Integrity with Metal Expandable Technology in Abu Dhabi

Background

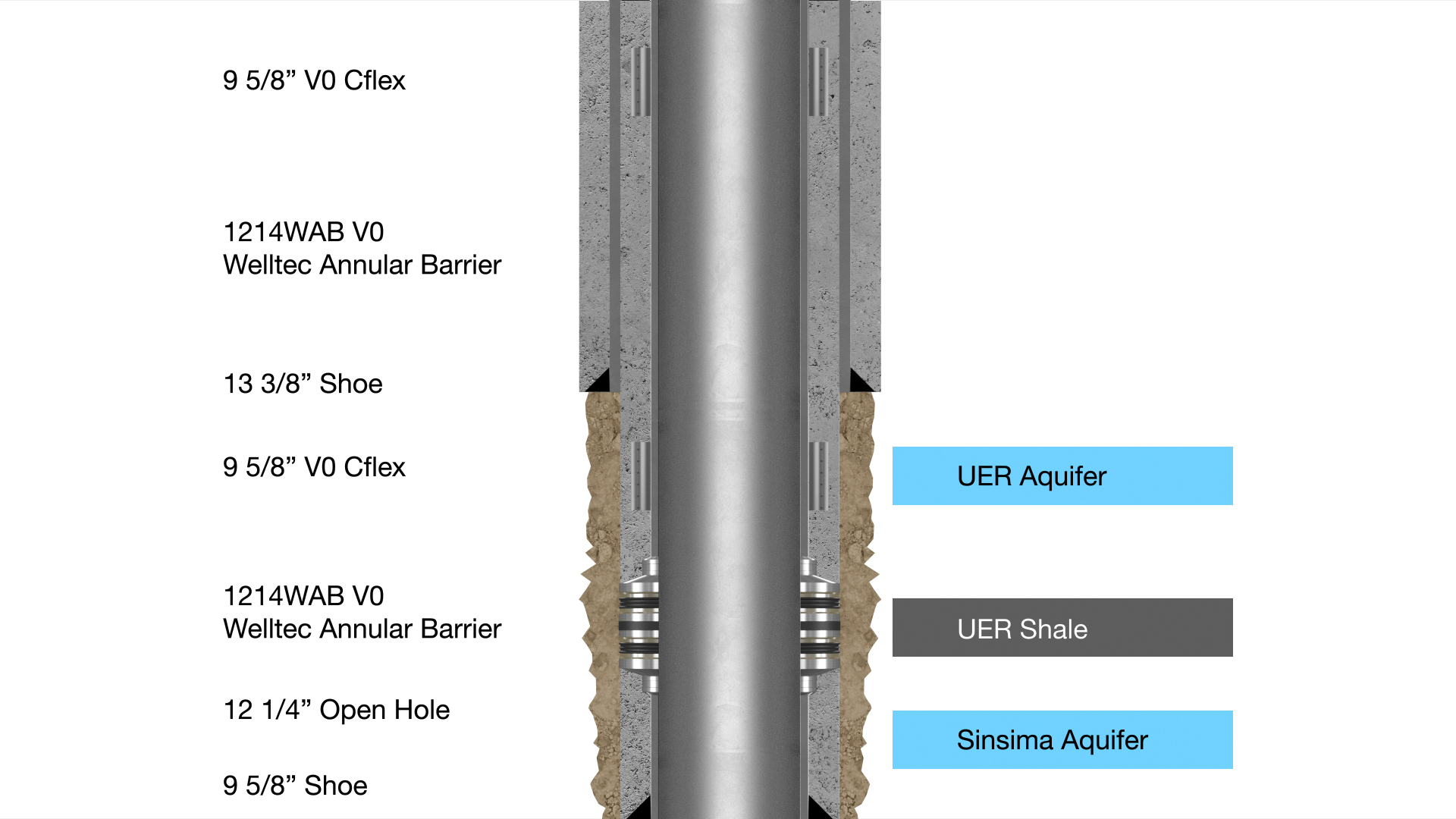

The Abu Dhabi National Oil Company (ADNOC) faced frequent challenges when drilling through and cementing depleted aquifer zones in mature onshore fields.

Traditional top-down cement squeeze jobs prove only moderately effective, leaving approximately 5,000 ft of inadequately cemented casing and compromising well integrity over time. This compromise not only poses a risk of aquifer water contacting the carbon steel of the casing but also introduces the potential for methane emissions as the compromised casing interacts with subsurface fluids.

Solution

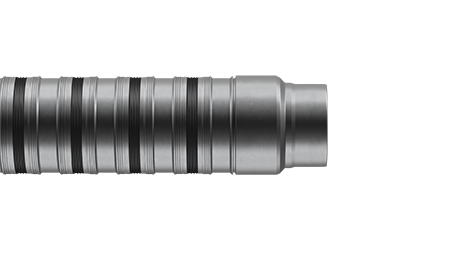

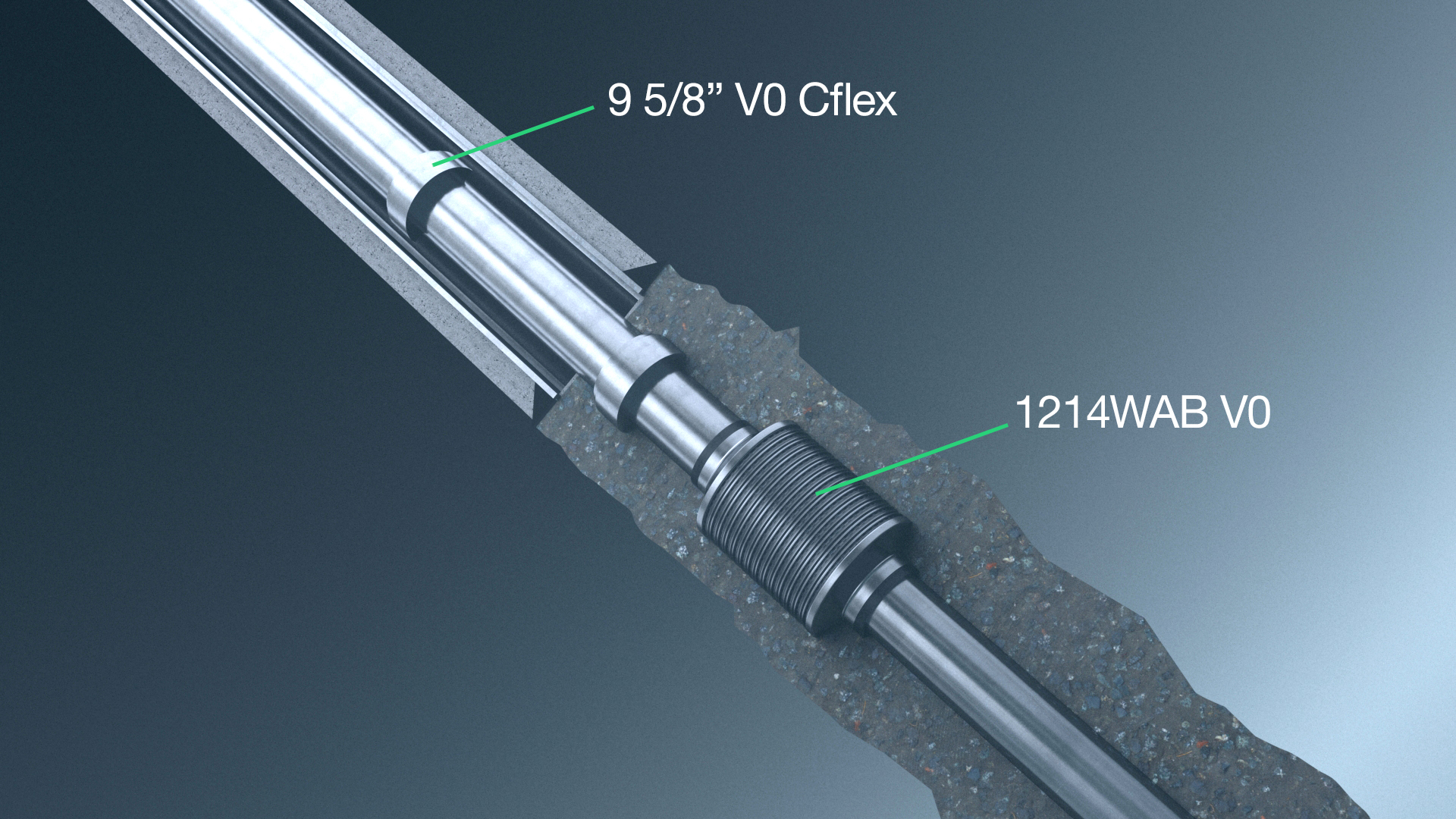

To address this challenge and prevent both well integrity issues and potential methane emissions, ADNOC collaborated with Welltec® to deploy the Welltec Annular Barrier (WAB®) with a two-stage cementing system. The goal was to assess the effectiveness of a metal expandable packer in preventing corrosion in wells experiencing severe loss scenarios.

A metal expandable annular sealing system proved to be a reliable isolation mechanism for effective cementation behind aquifers. The two-stage cementing system, operated by an inner string, placed cement above the metal expandable packer while maintaining casing integrity. This combination of technologies not only ensured zonal isolation but also offered a cost-effective life-of-well solution compared to traditional cementing methods.

Operation

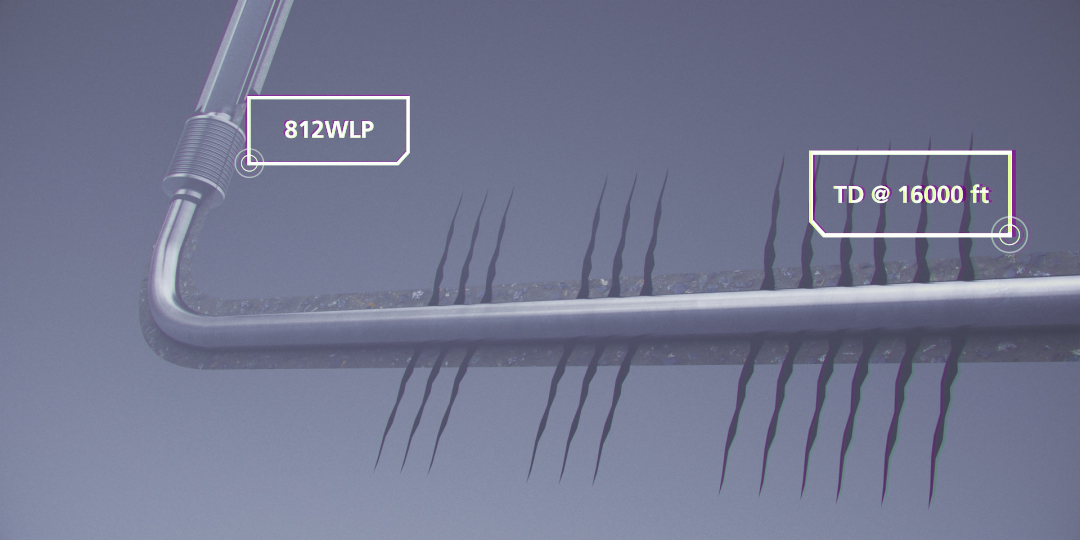

The 1214WAB was selected for the trial, and the tools were mobilized to the wellsites. The WABs were run in hole with a stage cementing port positioned above. The inner-string cementing system was deployed, and after the primary cement job, the WAB expanded.

The cementing port was shifted open, and cement was pumped above the WAB back to the surface. This efficient two-stage cementing operation was crucial for preventing methane emissions and ensuring the robustness of the well barrier envelope.

Achievements

Post-execution of the two-stage cement job, cement bond logs confirmed satisfactory isolation of the aquifer zones behind the 9-5/8” production casing. The pilot trials demonstrated enhanced cement quality across the aquifer zones, preventing potential methane emissions from compromised casings.

Beyond zonal isolation, the technology allowed a conversion from a heavyweight to a lightweight casing design, saving significant rig time and costs. The WAB, utilized in conjunction with the inner string and two-stage cementing, resulted in quicker deployment and well construction.

The true value, however, lies in Health, Safety, and Environmental (HSE) considerations. The robust well barrier achieved through this technology prevents process safety events, reduces the likelihood of production deferrals, and enhances profitability.

By preventing methane emissions and addressing well integrity issues, the technology showcased huge value for ADNOC Onshore, both in terms of operational efficiency and environmental responsibility. The approach not only safeguards against potential methane release but also contributes to the bottom line by avoiding costly shut-ins and lost production.

Well schematics