Case highlight

A Norwegian based IOC's, previous attempts to isolate and mitigate against SCP (sustained casing pressure) within the B annulus using various means and methods...

WAB® for Well Construction & Integrity

CAPEX effective, enhanced well integrity via metal expandable packers

Sustained casing pressure (SCP) is common in many wells globally (>30%) and present within multiple annuli. Since 2009, well integrity has cost operators over $75 billion. This has provided the impetus for the industry to focus on and rework international standards on well integrity management.

Through the incorporation of the WAB (Welltec Annular Barrier) to the well construction phase, Welltec® are facilitating enhanced well integrity via standalone cased hole barriers, open hole isolation and cement assurance.

At Welltec, we design and test our WAB range in accordance to IS014310, the industry standard which defines packer design validation grades.

Our V0 WAB range for cased hole SCP barrier has been tested to IS014310 V0*, the highest validation level within this industry standard, and provides, a verifiable, life of well barrier against SCP.

Our V3 WAB range for open hole isolation, has been validated to IS014310 V3*, the highest fluid validation level within this industry standard. The WAB provides life of well V3 isolation assurance within the open hole section. Additionally, it can be set within cement or used in combination with 2nd stage cement systems to support HP columns of cement to prevent SCP or production of unwanted gas or water.

*Leak rate criteria

A Norwegian based IOC's, previous attempts to isolate and mitigate against SCP (sustained casing pressure) within the B annulus using various means and methods...

An IOC had issues on the initial three wells of a seven well campaign whereby cross – flow between 2 x water zones was contaminating cement during curing and...

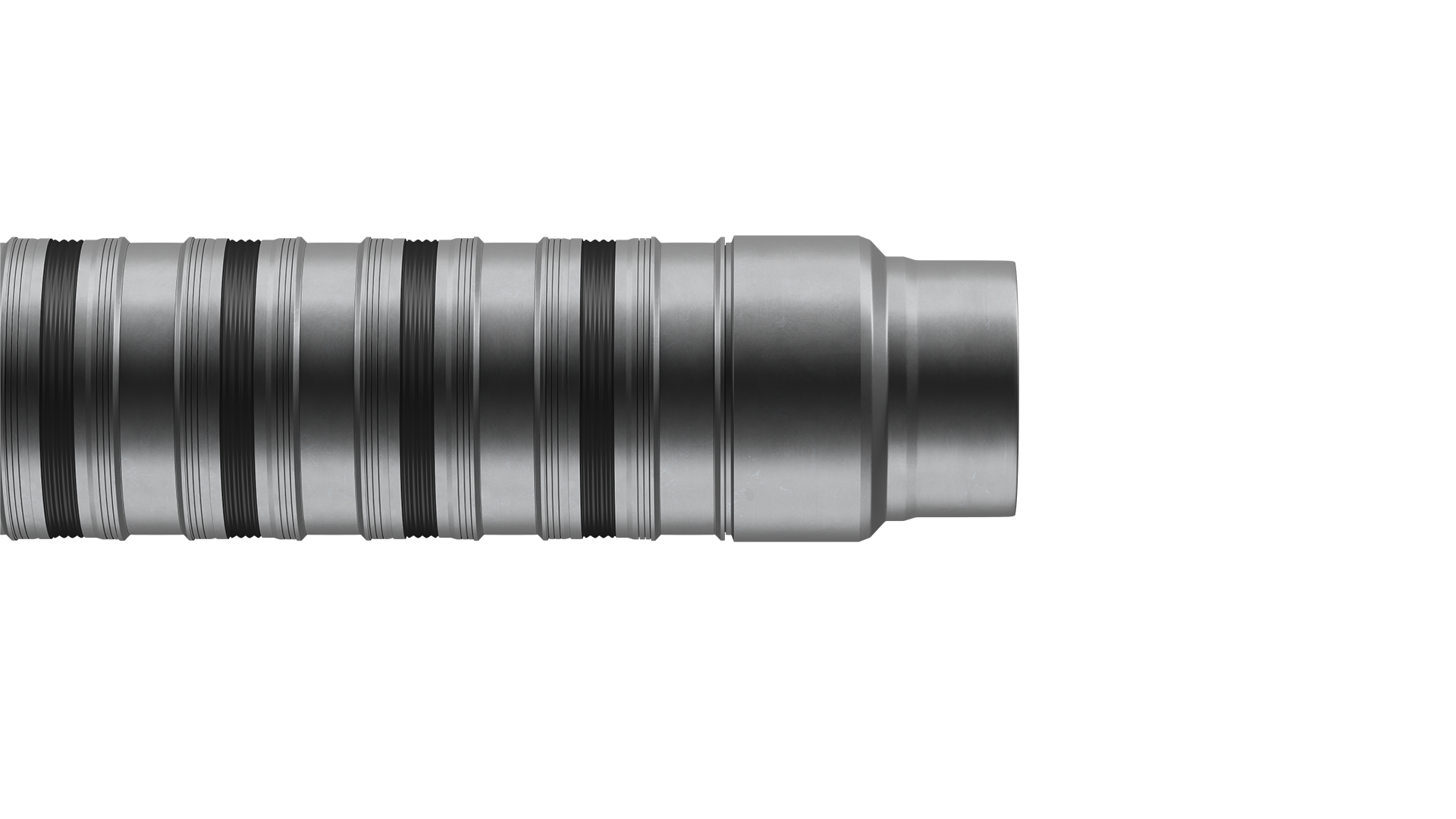

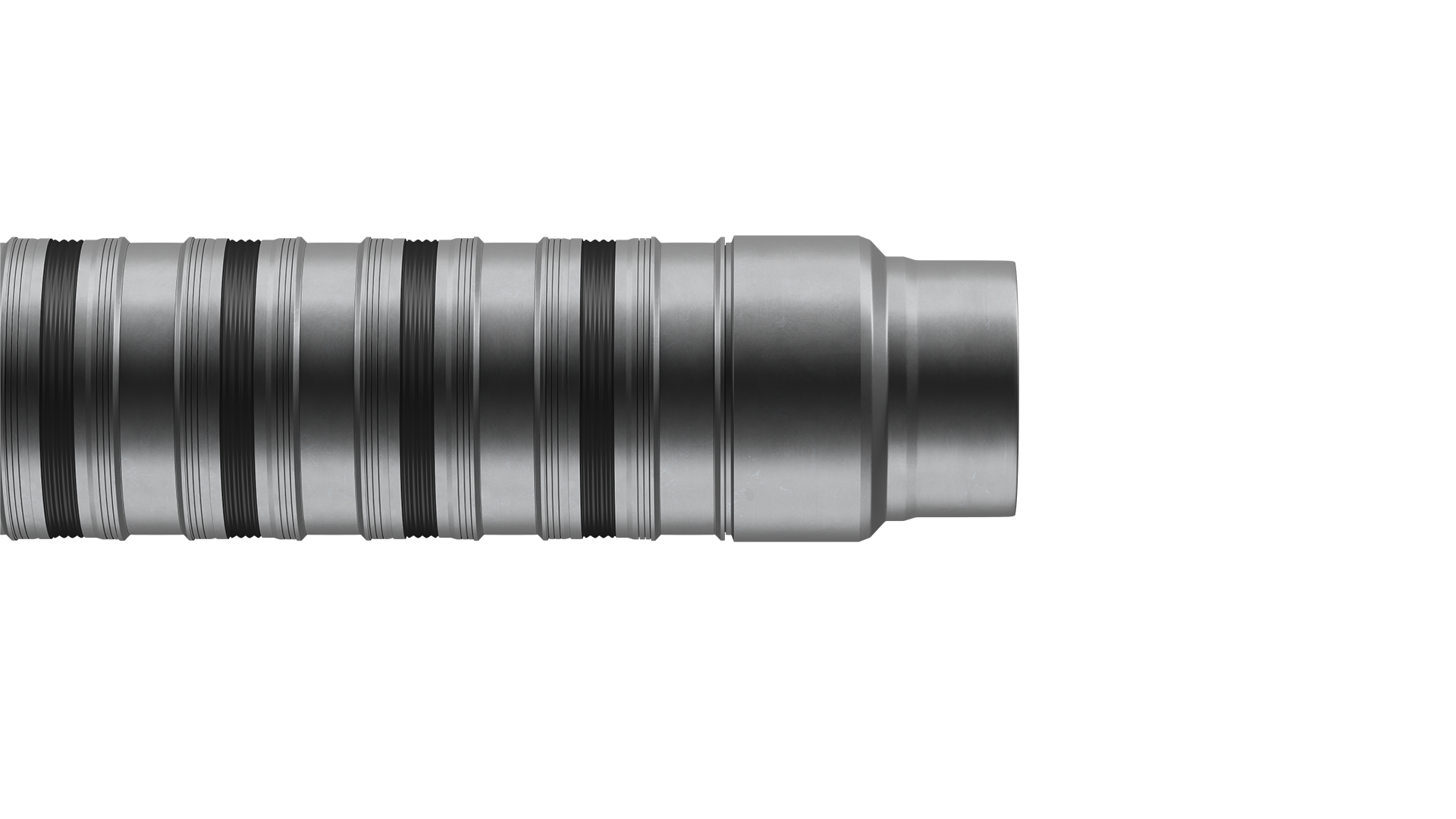

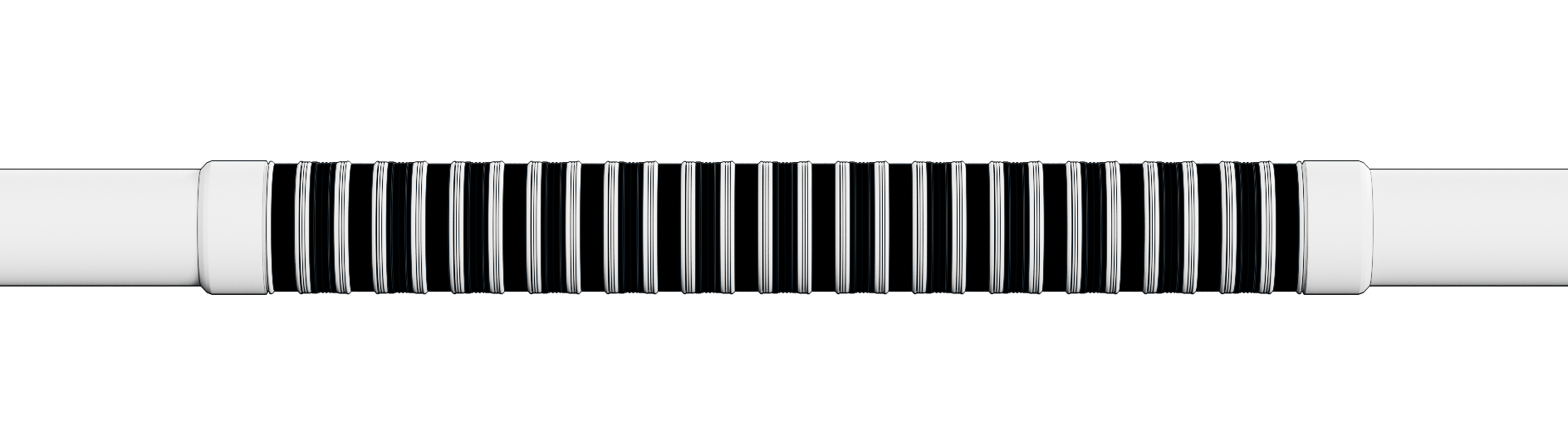

Our ISO 14310 rated, steel expandable WAB (Welltec Annular Barrier) is expanded between the base pipe and the casing or the borehole by applying pressure in the casing. It conforms to the actual well bore geometry or casing internal diameter and primary sealing with the casing or borehole is achieved through a patented series of V0 (cased hole) & V3 (cased or open hole) rated elastomer seals.

The WAB seals are optimized along the length of the steel sleeve, backed up by a series of metal fins that provide metal to metal or metal to rock contact, and high strength anchoring capability.

Once the WAB is set, casing Integrity is re-instated via internal hydraulic isolation mechanism.

The WAB can be mounted and welded onto any base casing in a simple and cost-effective way. Both ends are therefore fixed and provide life of well protection to the expanded WAB sleeve.

| Expansion range | 9.50” 23.50” |

|---|---|

| Min. running OD | 9.00” > 21.00” |

| Max. working pressure | 4,000 psi 8,000 psi |

| Constant element ΔP across expansion range | 4,000 psi 8,000 psi |

| Base pipe range | 7 - 5/8” > 18 5/8” |

| Standard element length | 7.2 ft |

| Temperature | 500°F |

| ISO14310 Standard | Up to V0 |

| ID | Full bore (as per base pipe) |