HIROS retrieves multiple fish to get important producer back online

- Well type Oil producer

- Max. deviation 76° at fish depth

- Max temperature 124°C / 255°F

- Max pressure 1,450 psi / 100 bar

- Pulling force applied 70,000 lbs

Background

A Norwegian offshore operator had an important producer well offline due to a stuck plug with a bottomhole assembly (BHA) attached to it. The problem was exacerbated by the accumulation of debris on top of the fish neck, and despite 18 runs including clean-out services, latching onto the BHA/fish proved impossible for a third-party service provider, leaving the best producer in the field in a state of impasse.

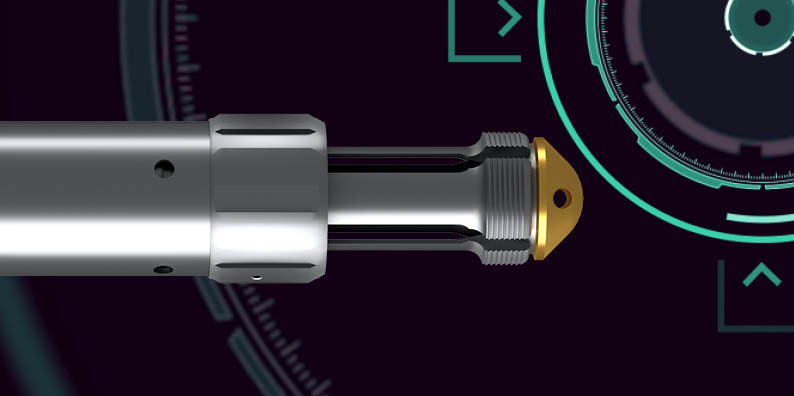

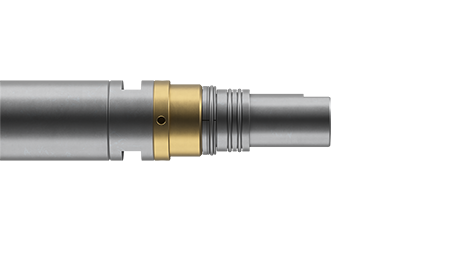

Mid-way through the fishing operation, which had now been awarded to Welltec, a new solution was added to the Wellgrab range: the Hi-Range Overshot and Spear (HIROS). HIROS is specifically designed to overcome situations where debris is impeding the latching process, utilizing an independent motor-driven grapple engagement system with up to 13,000 lbs of force available. Once latched, HIROS then has up to 100,000 lbs of push/pull force at its disposal.

The client’s prior first-hand experience of the excellent track record associated with Welltec’s downhole fishing solutions gave the impetus to the first-ever HIROS operation.

Operation

Welltec mobilized a complete tool suite to accommodate all aspects of the operation, including conveyance, clean-out, and fishing solutions.

The top of the BHA was latched on the first attempt, but after a downstroke of 8,000 lbs there was no indication of sheared pins. After one more stroke down, and three up (10,000 lbs), there was slow movement on the piston before an increase in speed, and tension dropped to 4,000 lbs after approximately 10 cm movement. The top of the BHA was retrieved, leaving the pulling tool and the plug it was attached to still to be fished.

Next, multiple clean-out runs were carried out due to the extent and variation of debris that was present at the top of the pulling tool and the plug, some of which had previously accumulated, and some of which fell during prior runs. After recovering ~12 liters of sand and scale debris back to the surface within the integrated bailer sections of the Well Cleaner®, subsequent attempts to latch onto the pulling tool were now within a few millimeters of success.

It was at this point that the HIROS solution was introduced, providing a range of configurable overshots and spears. Running in hole with the HIROS solution, the tool’s ability to run through scale to engage with the fish made the crucial difference, as the crew switched between different engagement settings to benefit from the different grapple extension. The comparison between the travel of the motor and the known distance required to latch (from surface testing) confirmed that the overshot fixture had latched, and the original pulling tool was finally recovered via 20,000 lbs of pull force.

Following a quick change from an overshot to a spear, HIROS was run back in hole to repeat the process of running through any remaining scale debris to latch onto the plug, which was retrieved via 70,000 lbs of pull force.

Achievements

This first-ever HIROS deployment brought an 83-day shut-in period to an end, reinstating the best producer in the field, succeeding where other technologies had been unable to do so.

The introduction of HIROS, mid-way through an ongoing operation made the crucial difference to achieving success, with the user-specified engagement force settings helping overcome continually falling debris which was impeding the latching process on two separate fish.

Through the deployment of advanced tools and meticulous execution, Welltec demonstrated its ability to overcome complex well challenges and deliver tangible results for its clients.