First E-line horizontal fishing in Vaca Muerta

- Well type Horizontal oil producer

- Max. deviation 90.46° @ 12,116 ft (3,693 m)

- Max. achieved depth 13,704 ft (4,177 m), fish depth

- Max. well depth 18,930 ft (5,770 m)

- Temperature 223°F (106°C)

- Pressure 9,400 psi

- Distance tractored 2,959 ft (902 m)

Background

While performing a simultaneous plug-and-perf (PnP) operation in July 2019, an operator in Argentina was forced to halt operations because of an unintentional weak point disconnection. This resulted in 48 feet (14.60 m) of bottom-hole assembly (BHA) lost in hole.

The operator needed to recover the BHA to continue with the fracking program. Because of the simultaneous operations on the five-well pad, fishing with traditional coiled tubing (CT) would require halting fracking operations on the other wells. Additionally, if the operator chose CT, they would lose valuable time waiting for CT availability, mobilization, and rig up/down. The operator desired an intervention that would aid in increasing pad efficiency despite this setback. Welltec® had previously performed successful plug recoveries for the operator and was asked to propose a solution for this fishing job along with possible contingencies.

Operation

The client initially approached Welltec to vertically fish a PnP BHA at 492 ft (150 m). Prior to fishing, the client performed a run to identify the BHA depth and possibly get a lead impression of the fish neck. The e-line run with the impression block reached a maximum depth of 558 ft (170 m), but upon recovery at the surface, no impression was found. As a contingency for another disconnection, Welltec added a Welltec® Release Device (WRD) below the Well Stroker® and also above the fishing overshot.

For the first run, personnel estimated the target depth at 558 ft (170 m) based on the failed first run and on the assumption that the plug on the fish was activated. For this reason, only the Well Stroker and WRD were used. The toolstring descended to 2,461 ft (750 m) but did not locate the BHA.

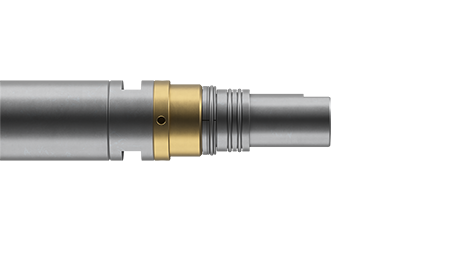

For the second run, a Well Tractor® was added, so the toolstring could be conveyed throughout the high angle well. To keep the toolstring as short as possible to fit inside the lubricators, a two-wheel section of the 3-1/8” Well Tractor was used. The fish was located at 10,764 ft (3,281 m) at an 80° inclination. After several attempts to push the fish with the Well Tractor and latch it with the Well Stroker, the fish began to move. The Well Tractor pushed the fish to 11,460 ft (3,493 m) where it no longer went forward, possibly due to sand residues from previous fracking. The client next pumped a cleaning batch.

For the last run, a wheel section was added to increase the Well Tractor’s pull force after the client approved using part of the frac stack as a pocket if the BHA was recovered. The Well Tractor was activated at 10,745 ft (3,275 m) and pushed the BHA against a plug at casing collar locator depth of 13,704 ft (4,177 m). At this point, the Well Stroker was activated and stroked down to hook the fishing tool to the BHA. A tension test then confirmed that the BHA was attached.

Achievements

The Well Tractor successfully conveyed the loose BHA with an unactivated plug to a depth that permitted force where the Well Stroker actuated with the overshot and latched onto the objective. Additionally, the WRD was available as a contingency if needed.

Running this horizontal fishing operation on e-line reduced the rig-up/down time, left a smaller operational footprint, and provided quicker logistics than a traditional CT operation. Furthermore, simultaneous operations were performed and five fracking stages were completed during Welltec’s operation. Finally, despite two additional runs—due to the initial assumption that the toolstring was in the vertical section—this operation saved 24 hours when compared with CT.

The clientThis sets a positive precedent that will allow further flexibility in our contingency operations of PnP and will for sure trigger a change in our workflow.