Innovative approach to zonal management increases production in Caspian Sea

- Well type Oil Producer

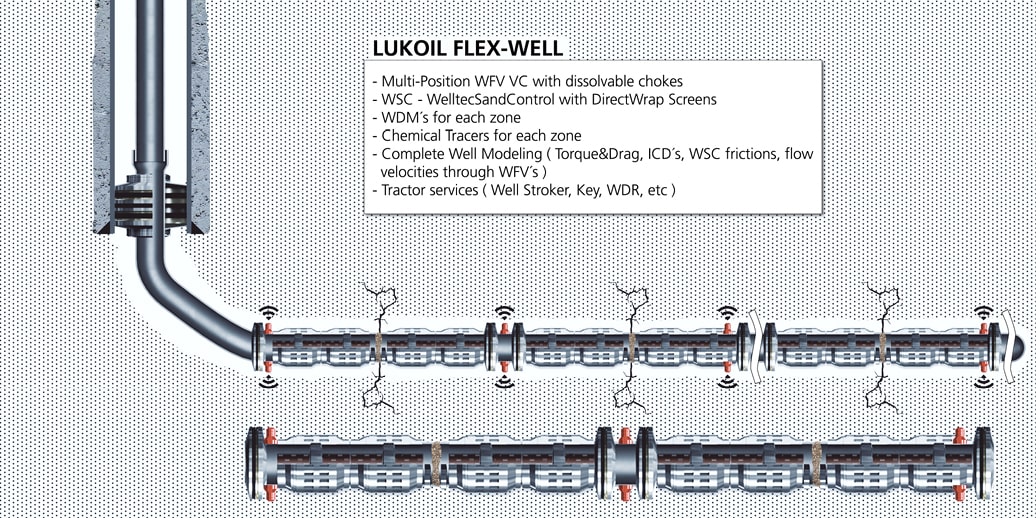

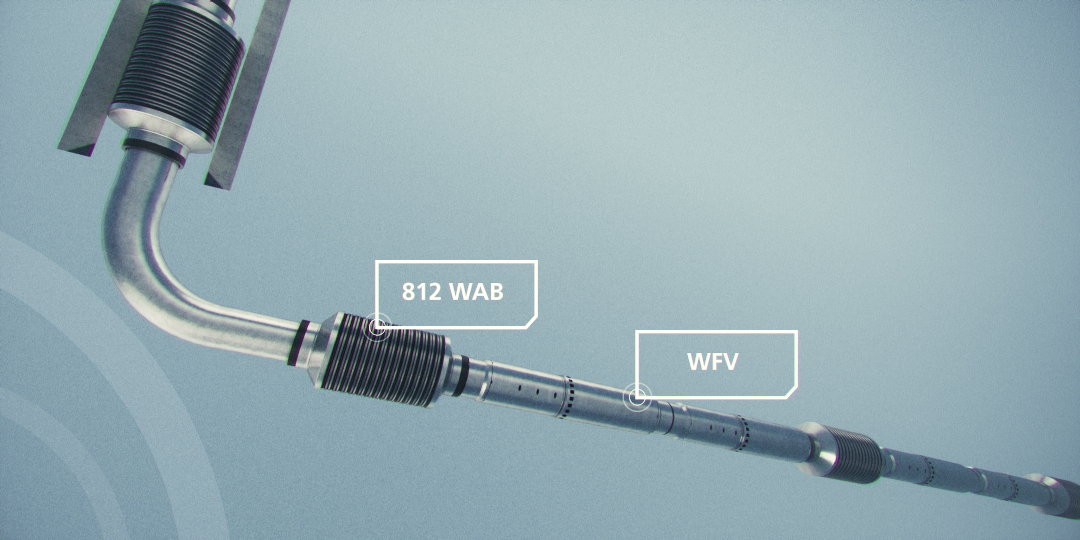

- Pilot well To provide Welltec Sand Control together with WFV

- Location Russia

Background

An operator in the northern Caspian Sea needed to complete an extended-reach drilling (ERD) well with robust, intelligent lower completions. The 2,200 m of open hole and shallow vertical depth of the ERD well required rotation with the ability to circulate and displace the open hole to completion fluid to reach the lower completion.

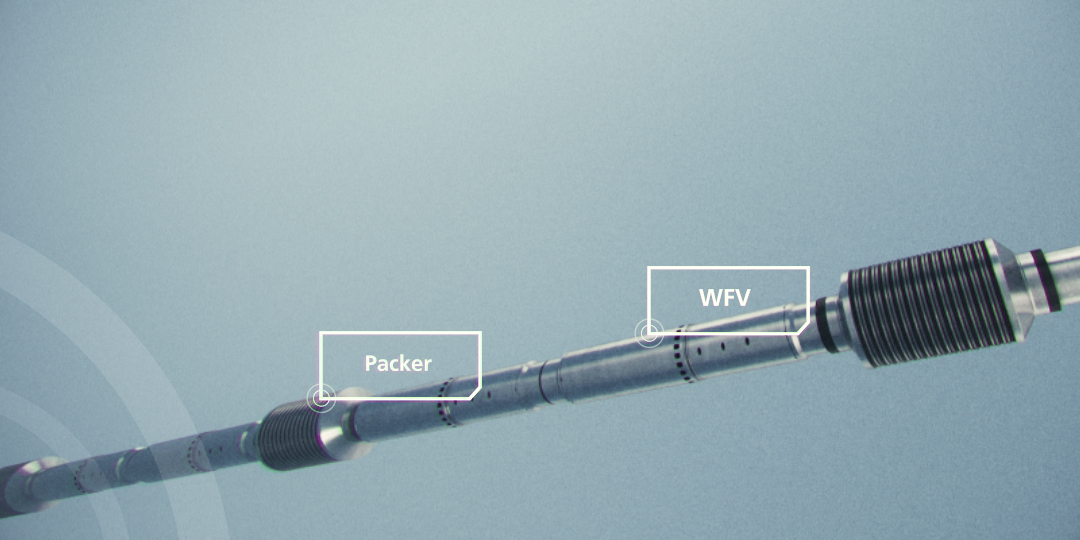

Owing to a massive gas cap above the reservoir with water below, the operator needed zonal isolation for future flow management, specifically inflow control devices (ICDs) for passive management and flow valves for active management. The operator wanted to lower future risk by reducing the number of flow valves and manage zones with an e-line tractor in a single run.

The operator had tried solutions from several service providers on prior wells but was unhappy with the cost of their lower completions. In addition, each service provider faced significant challenges in deploying lower completions or intelligent completions to the desired depth.

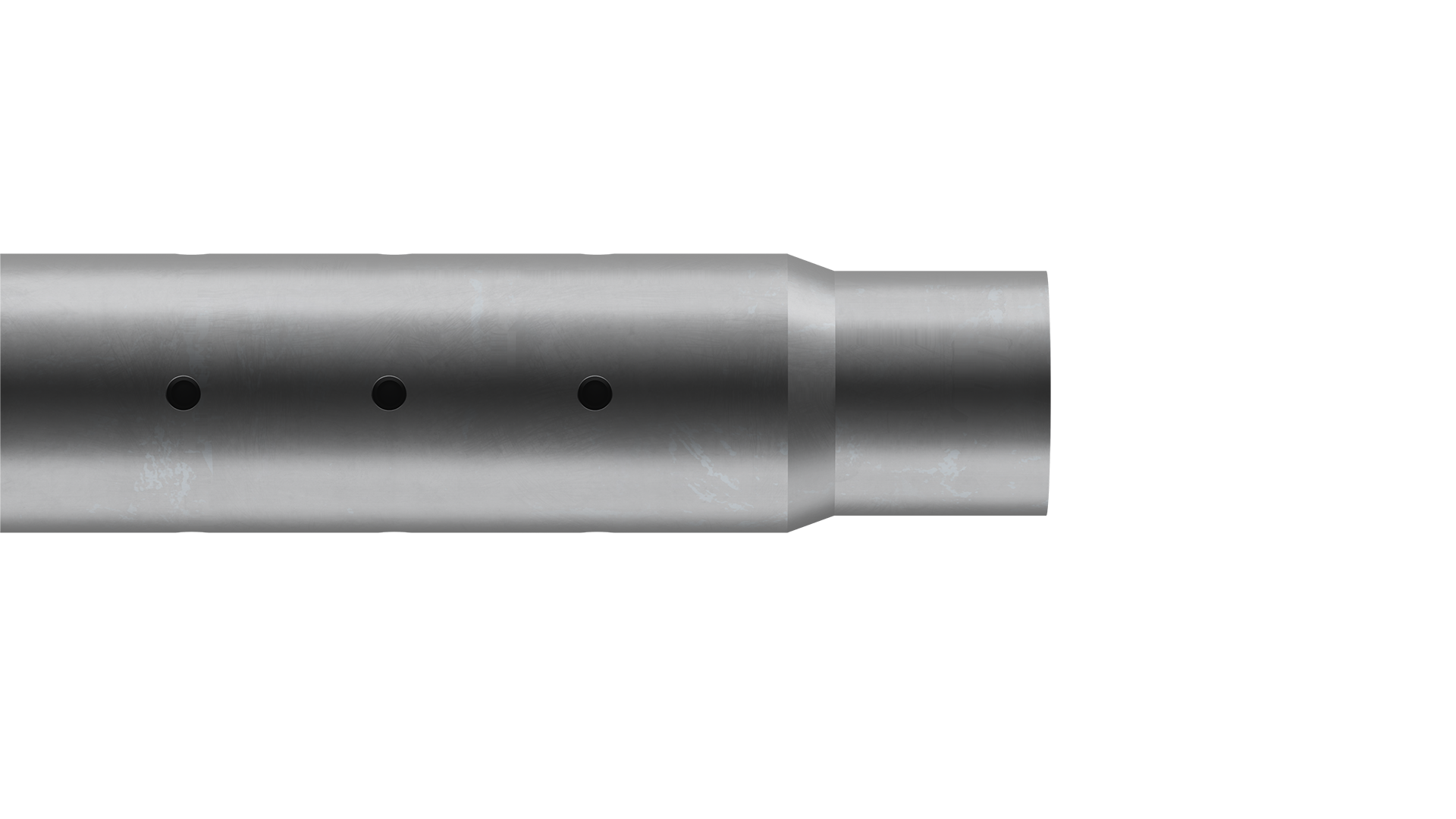

Welltec® proposed a solution consisting of Direct Wrap Screens and Multi Position Welltec® Flow Valves. The assembly can be rotated to reach the bottom. Although other providers can rotate screens, the Welltec solution is more robust because it has shrouds and centralizers at each sand screen connection

Operation

Welltec began by building a test well at the manufacturing facility to test the assemblies and then performed a successful systems integration test for the client to demonstrate the reliability of the Flex-Well. Additionally, ICD modeling evaluated zonal splits, flow valves, and production scenarios to justify the number of flow valves and assure the client that the required production would be met. Welltec then mobilized to the well and ran in well the Flex-Well, rotating for the last 100 m and displacing the open hole to completion fluid. Surface readout confirmed that the flow valves were in position.

Six months later, after analyzing results of a production logging tool, the client determined that the well required further intervention to reconfigure the flow valves and optimize production. The client decided to access two main zones—the well’s toe and middle section.

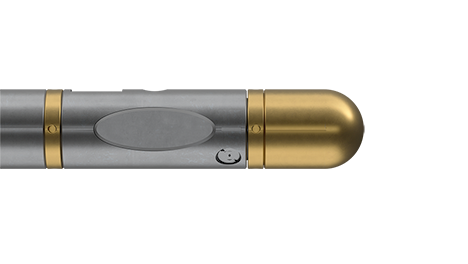

The Well Tractor® conveyed the Well Key® and Well Stroker® to the flow valves. A high-expansion stroker was used to perform the shifts, and an internal limiter was used to achieve the exact travel distance for each stroke. The stroker made 64 strokes in one run to manipulate the flow valves. Three full open-close cycles were made for the toe flow valves. The final shifting increased crude oil production (+100 tons of crude) and reduced gas production (-70,000 m3 of gas).

Achievements

The client considered this pilot operation with the Flex-Well an absolute success. This novel completion design has not been used prior to this operation. The Welltec® Sand Screens were implemented to minimize the number of flow valves. Only 20 flow valves were used in this completion, compared to an average of 80 in other providers’ completions. The operation incurred zero non-productive time during the Flex-Well installation. The well achieved target oil production from the start.

As seen in this case, the Flex-Well is easily operated by the Well Tractor to achieve production targets. The Multi-Position Welltec Flow Valves give clients flexibility for their zonal-isolation needs, and the reduced number of flow valves in the well allow the client to shift valves and monitor production in real time before pulling the intervention assembly out of the hole.

During the intervention to adjust flow valves, the Well Stroker achieved a world record by making 64 strokes in one run. This intervention resulted in increased oil production—to 30% of crude oil—and decreased gas factor and free gas in production.

Welltec offers operators the ability to run long assemblies of Flex-Well lower completions with little risk to manage any zone at any time using the Well Tractor.

Well schematics