Overview

General information

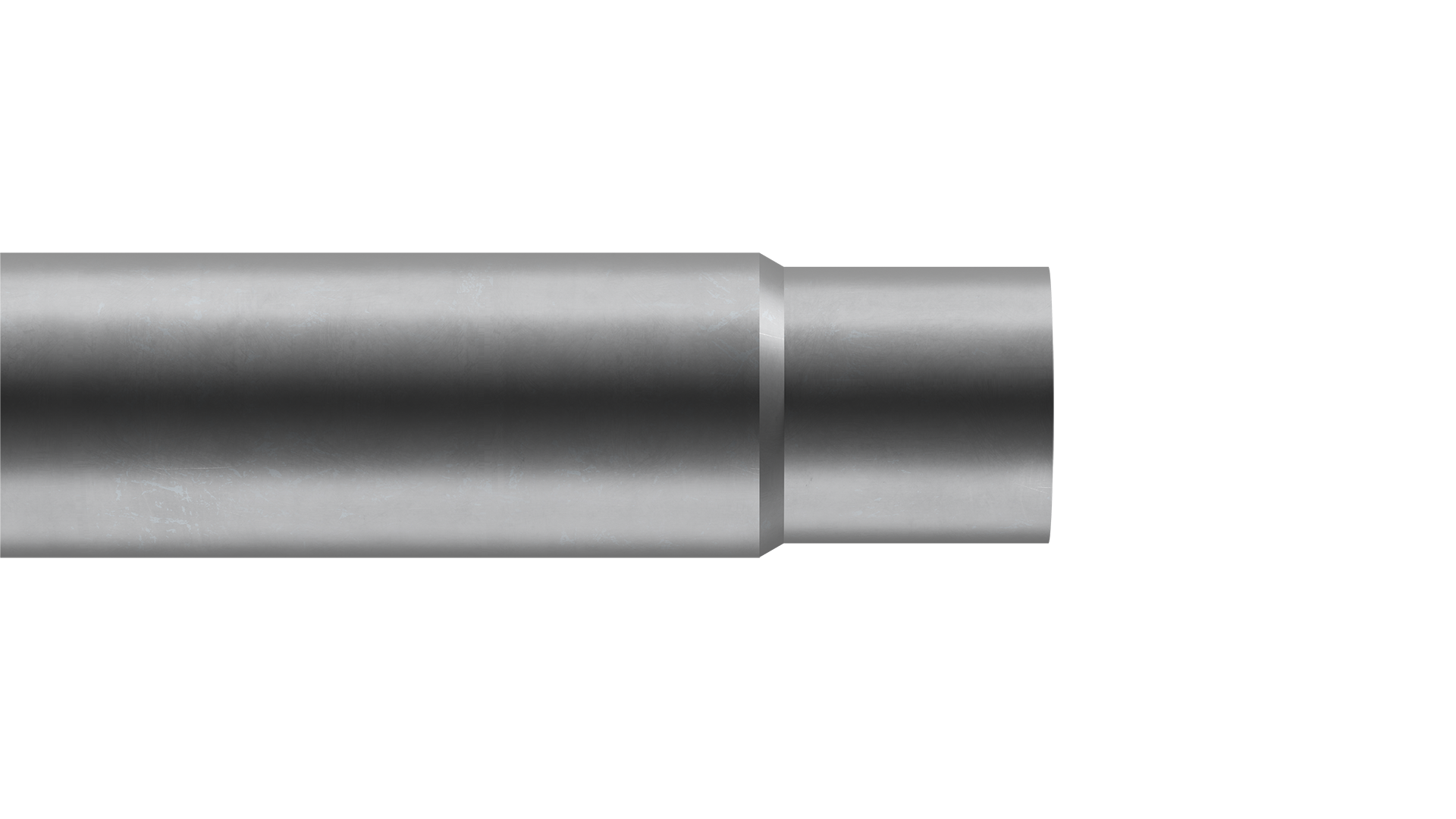

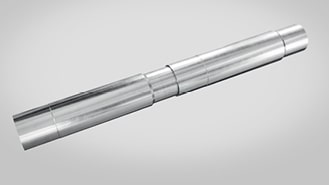

Product name: WIV (Welltec Isolation Valve).

Product structure: ball-drop activated, bi-directional seal

Base casing: compatibility with all standard casing material / weight / threads

Metallurgy: 4140 / S13 Cr / 25 Cr / Inc 718 / 925

Primary seal type: o-ring

Standard elastomers & seals: HNBR (160°C) / Aflas (200°C) / FFKM (260°C)