Reducing environmental impact in O&G Completion

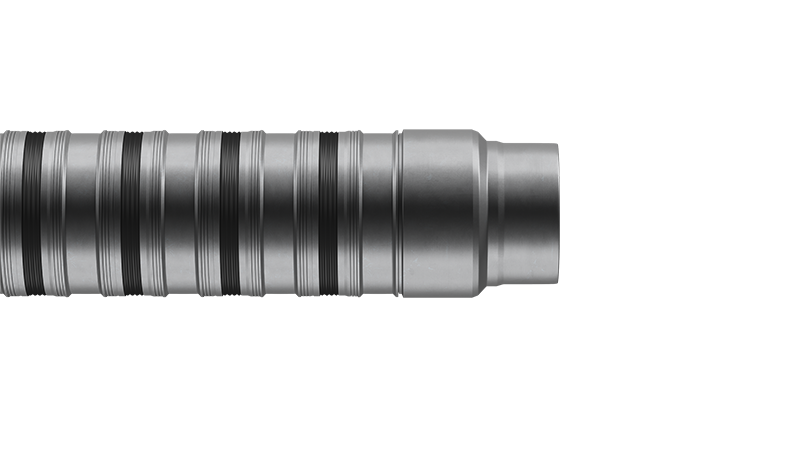

Welltec continues to develop innovative solutions and technologies that help our clients to optimize their production and reduce their environmental impact.

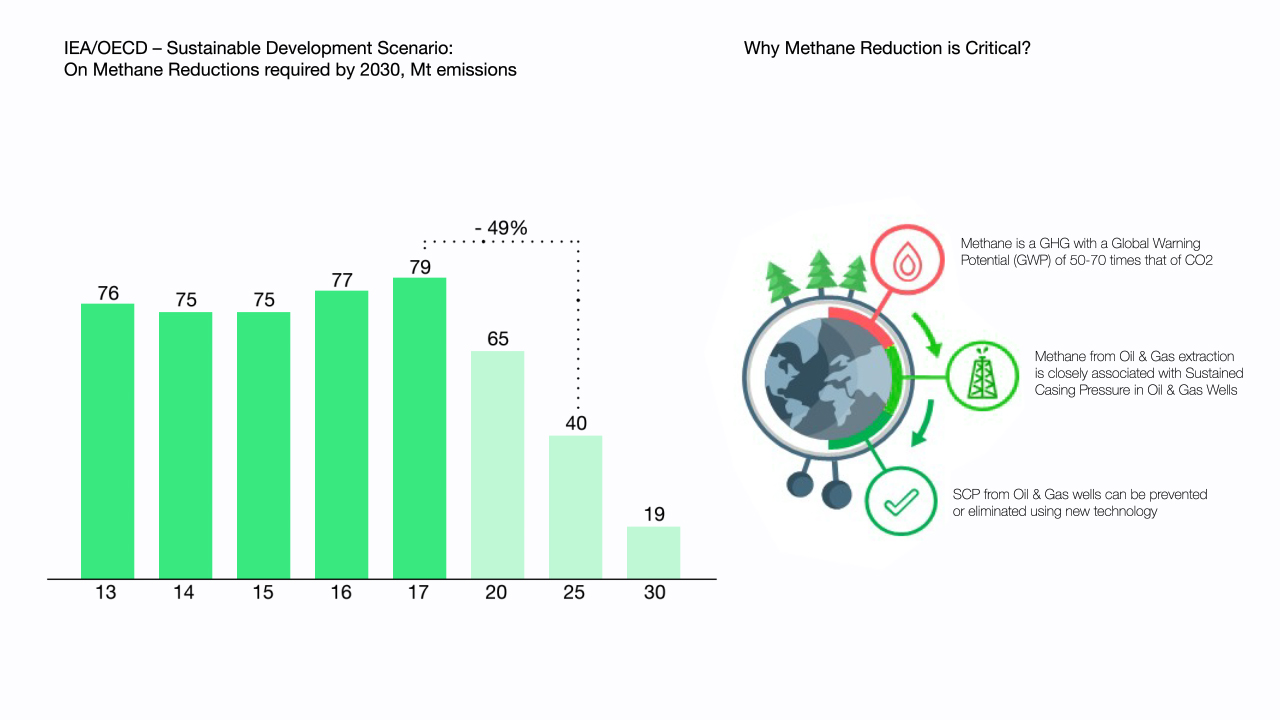

We cannot change chemistry. There is an inherent amount of carbon within the hydrocarbons that are produced from the Earth but reducing the industry’s carbon footprint in operations is now in focus more than ever and Welltec plays a key role in this greenhouse gas (GHG) reduction drive.