Well Miller® demonstrates novel geothermal intervention by milling silica scale

Background

In recent years, Welltec® has offered geothermal operators an innovative life-of-well solution with the Welltec Annular Barrier (WAB®) for zonal isolation. Welltec has continued to innovate in this space by testing interventions to maintain ideal and efficient production within these wells.

In terms of maintenance and intervention, silica (SiO2) scale is one of the primary causes of flow production restriction in geothermal wells. In particular, the challenge faced with this type of scale build-up stems from its strength and high level of resistance, making it incredibly difficult to mill. Innovative cleaning tools from Welltec have proven highly successful during testing for geothermal well cleaning applications.

Operation

To simulate the kinds of SiO2 scale found in geothermal wells, a cured blend of SiO2 pieces, sand, and epoxy resin were used. This kind of scale plagues geothermal wells and chokes production of the highest capacity energy within the renewables market.

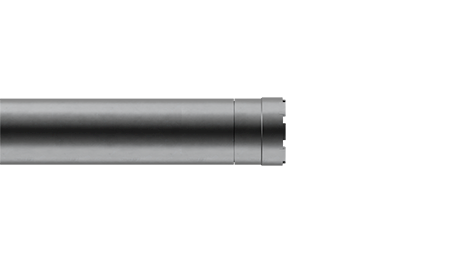

The Well Miller® Reverse Circulating Bit (RCB) was used to address this scale buildup in the test. The Well Miller RCB is a combinable milling tool that enables the simultaneous milling, break-up, and extraction of scale. The RCB also features a turbine section that circulates well fluid through the milling bit and collects any cuttings or debris into bailer chambers for later recovery once tools are rigged down at the surface.

During the test, the RCB successfully removed the SiO2 scale buildup. Even more impressive, the mill bit—composed of highly resistant tungsten carbide milling teeth—showed almost no signs of wear following the test.

Achievements

The success of the Well Miller and RCB in removing SiO2 scale build-up is a boon to geothermal operators, offering them the same lightweight interventions that oil and gas operators have used for years. The Well Miller offers significant capabilities for the geothermal market, including SiO2 removal, rigless intervention, minimal operational footprint, and savings in time and cost through a fast intervention operation.

Welltec continues to collaborate with industry experts and academic researchers to provide technology for research projects with allocated funding from the U.S. Department of Energy. With the ongoing development of Enhanced Geothermal Systems (EGS), Welltec’s geothermal options expand the potential to facilitate more efficient and sustainable methods that harness the Earth’s renewable natural energy sources.