Case highlight

An onshore well in Trinidad & Tobago had to be shut in due to a corroded 6-5/8” production casing at 355 ft, and as a consequence, Heritage Petroleum Company lost production from the asset...

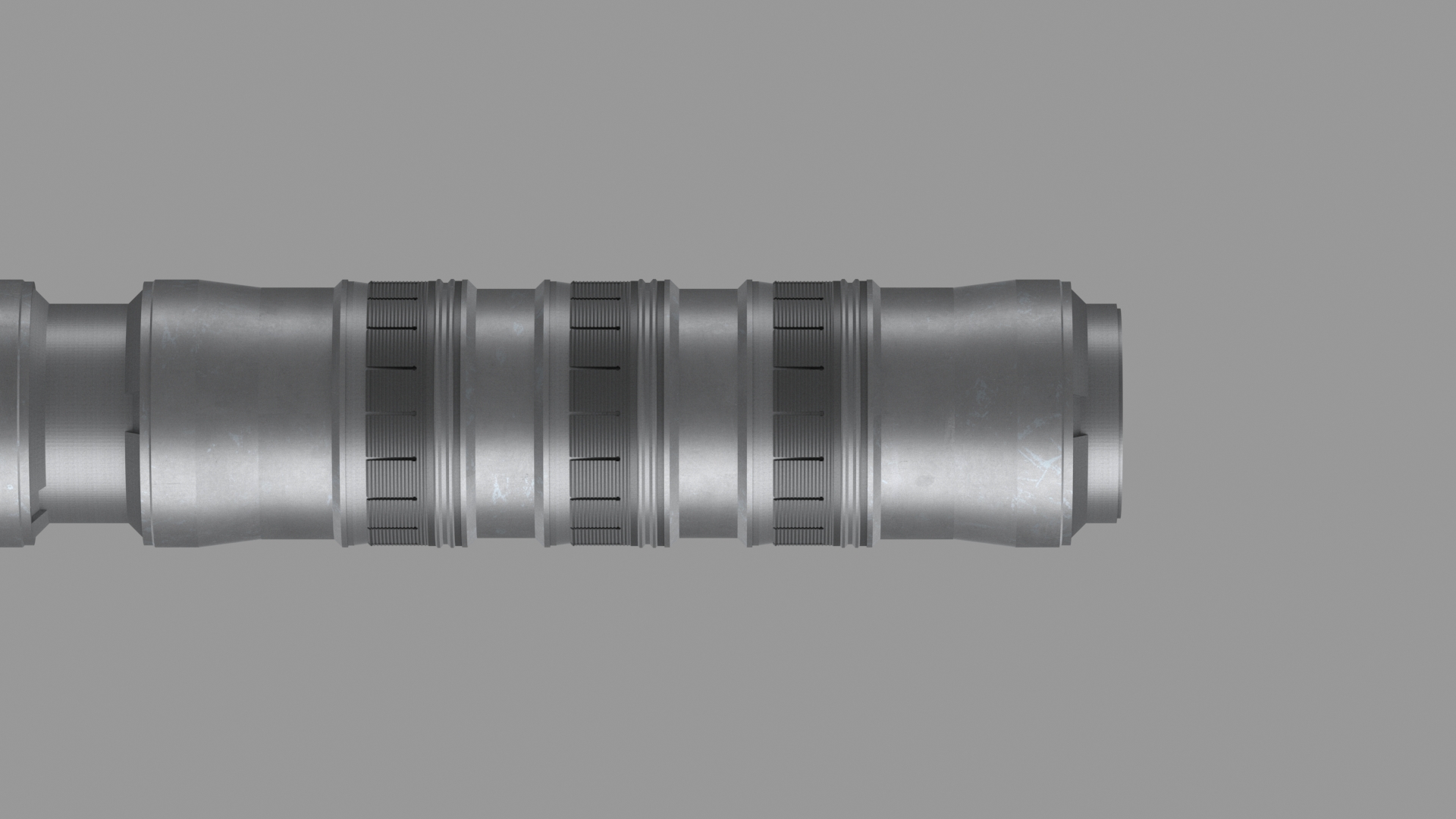

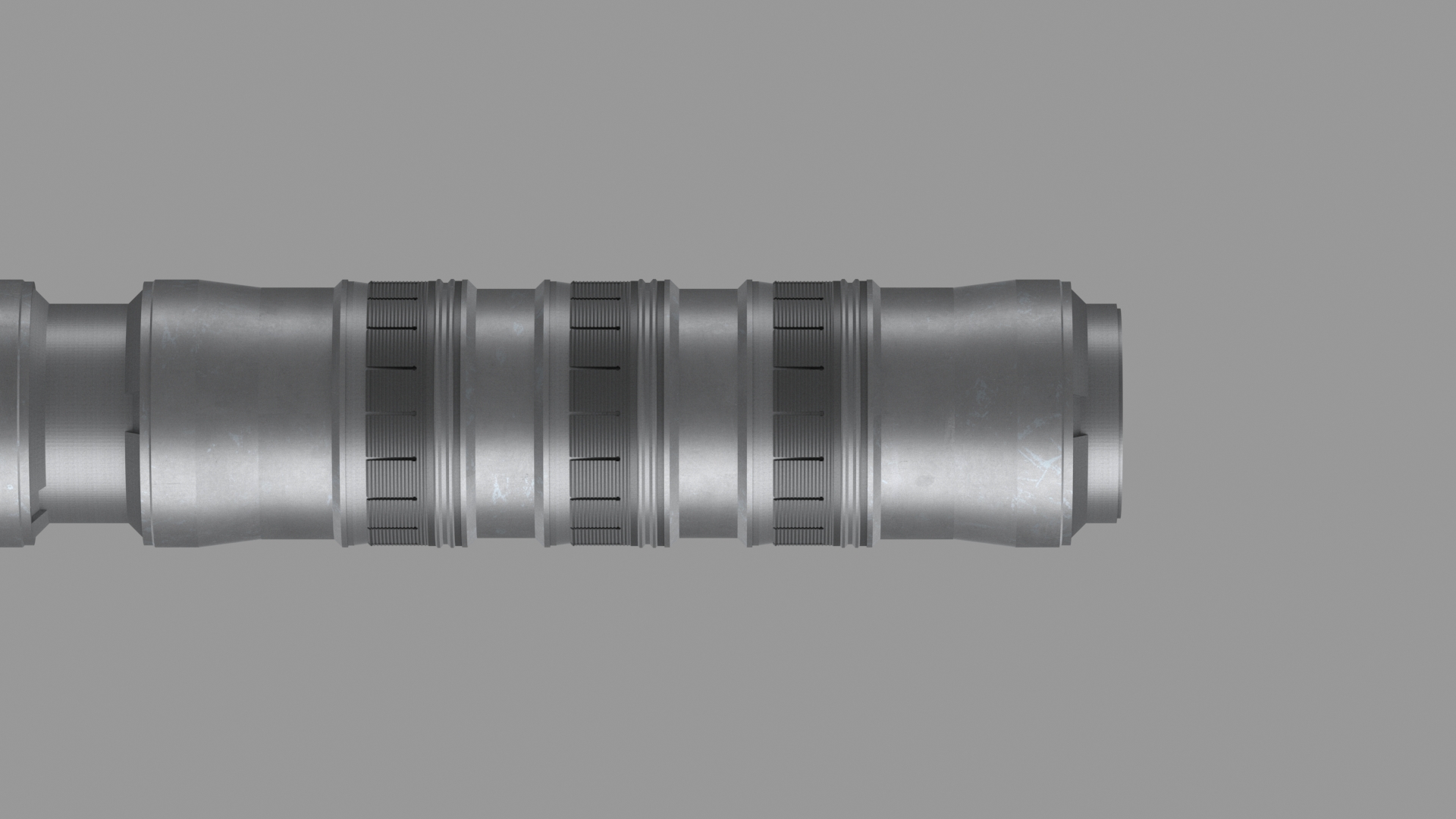

Welltec® Expandable Anchor (WEA) for Tieback Liner

Anchoring in cased hole

The Welltec® Expandable Anchor (WEA) for Tieback Liner is qualified for life-of-well, delivers maximum running clearance, and eliminates the need for further intervention runs, cementing, or waiting on swell time. Surface-controlled hydraulic expansion ensures bidirectional anchoring and sealing.

The solution is qualified in accordance with the highest-level API 19LH-V1 standard.

The development of the WEA as a Tieback Liner minimizes subcomponents, ensuring reliability and efficiency while simplifying well construction. The WEA enables reciprocation, circulation, and/or rotation during deployment.

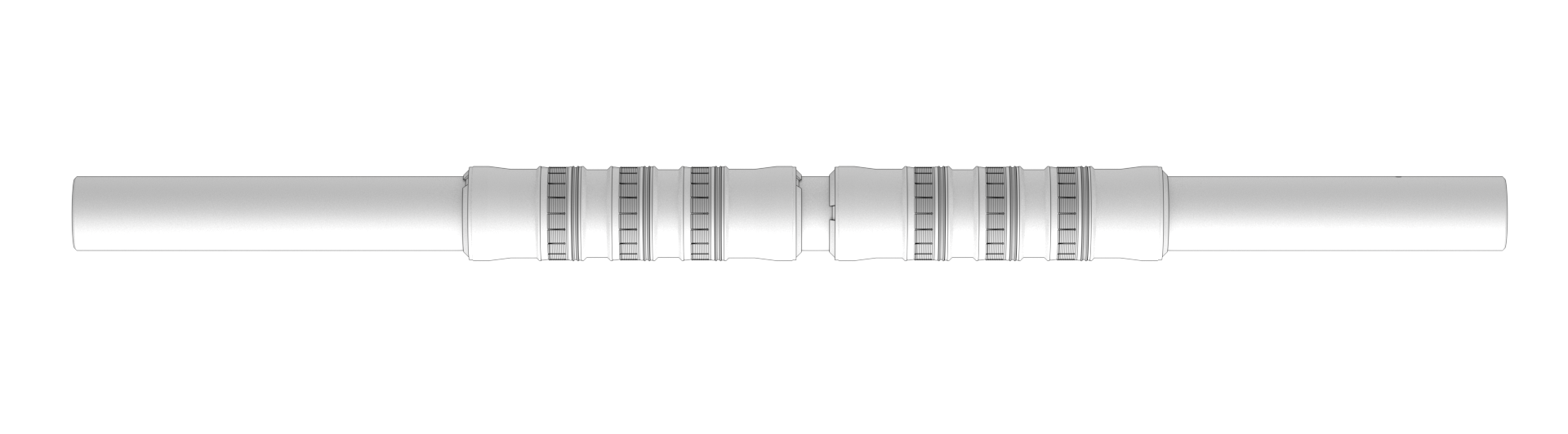

The Welltec Expandable Anchor (WEA) for Tieback Liner can be run standalone or in combination with a Metal Expandable Packer (MEP), the proven hydraulic expansion sleeve. The rapid application of surface-controlled pressure simultaneously expands the WEA and the MEP system, offering an efficient alternative to conventional tieback solutions. The expansion sleeve hydraulically expands the bidirectional anchors, which uniformly engage with the ID of the outer casing. Increased loading/anchoring capacity is achieved via the modular addition of WEA sleeves. The slim running OD maximizes clearance to have minimal impact on ECD during fluid circulation of cementing operations.

An onshore well in Trinidad & Tobago had to be shut in due to a corroded 6-5/8” production casing at 355 ft, and as a consequence, Heritage Petroleum Company lost production from the asset...

The WEA is a single-piece machined sleeve, fully welded to a base pipe. The main anchor section is a machined slip that is mounted over the expansion sleeve.

The functionality and characteristics of the expansion sleeve are similar to that of Welltec’s metal expandable packer range. As the sleeve expands, the anchor rings engage with and grip the liner/casing ID. As the load is applied, the grip is increased, and increased load anchoring can be provided via additional sleeve assemblies.

The WEA range is fully compatible with Welltec® Metal Expandable Packers and WIV® technologies.

* Custom specifications and control line feedthrough options available on request.

| Set within a tubular range | 6 5/8” 13 5/8” |

|---|---|

| Base-pipe range up to | 4 ½” 9 5/8” |

| Expansion range | 5.75" 12.38” |

| Maximum running OD | 5.6" 11.38” |

| ID | Full bore (as per base-pipe) |

| Qualification | API 19LH – V1 |

| Expansion pressure while setting | 4,500 psi 5,000 psi |

| Anchoring capacity | Up to 80% of the tensile strength of the base pipe |

| Differential pressure | 10,000 psi |

| Temperature range °C | 30°C 130°C |

| Compatible with | Metal Expandable Packers |

| *Custom specification and control | line feedthrough options available on request |