Reinstating production of a shut-in well by relining and isolating corroded casing

- New completion solution First global deployment

- Restored production Isolated corroded casing

- Cost-effective and assured solution Life-of-well isolation

Background

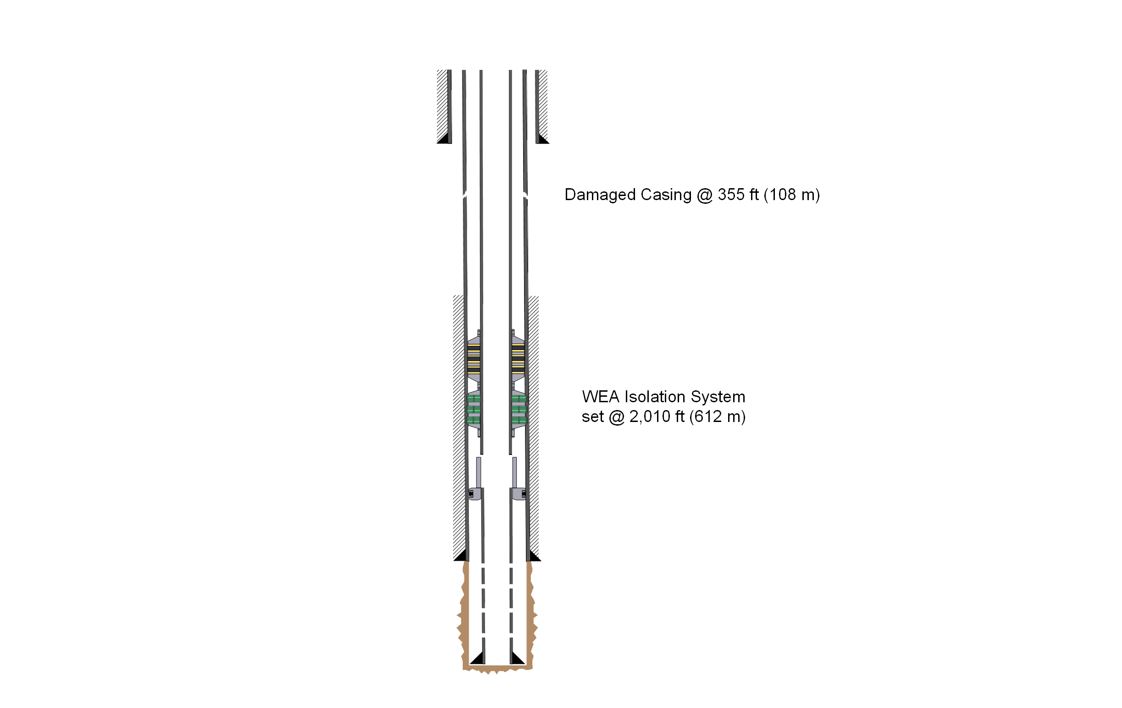

An onshore well in Trinidad & Tobago had to be shut in due to a corroded 6-5/8” production casing at 355 ft, and as a consequence, Heritage Petroleum Company lost production from the asset.

Initial considerations for remediation included: to cement squeeze the leak and run a straddle, or to perform a bottom-up cement squeeze from the scab liner. However, both of these options were considered costly and carried an associated risk with regards to cement placement and the likelihood of achieving life-of-well sealing/integrity.

Welltec® proposed a newly designed and qualified solution incorporating the Welltec® Expandable Anchor (WEA), which among its multiple potential applications served in this instance as a well relining solution in order to isolate the corroded section of casing.

Operation

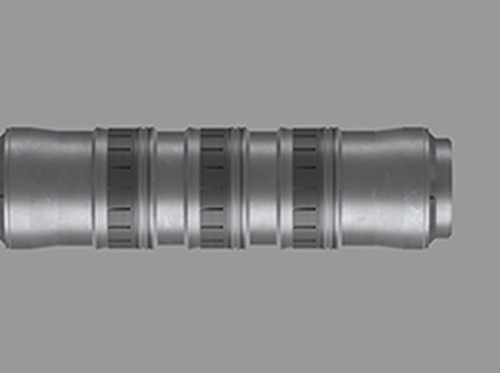

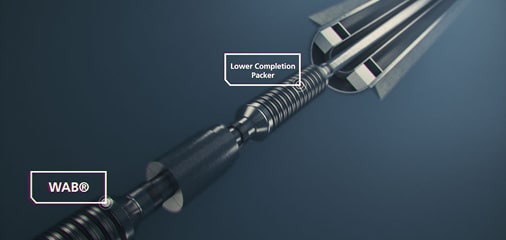

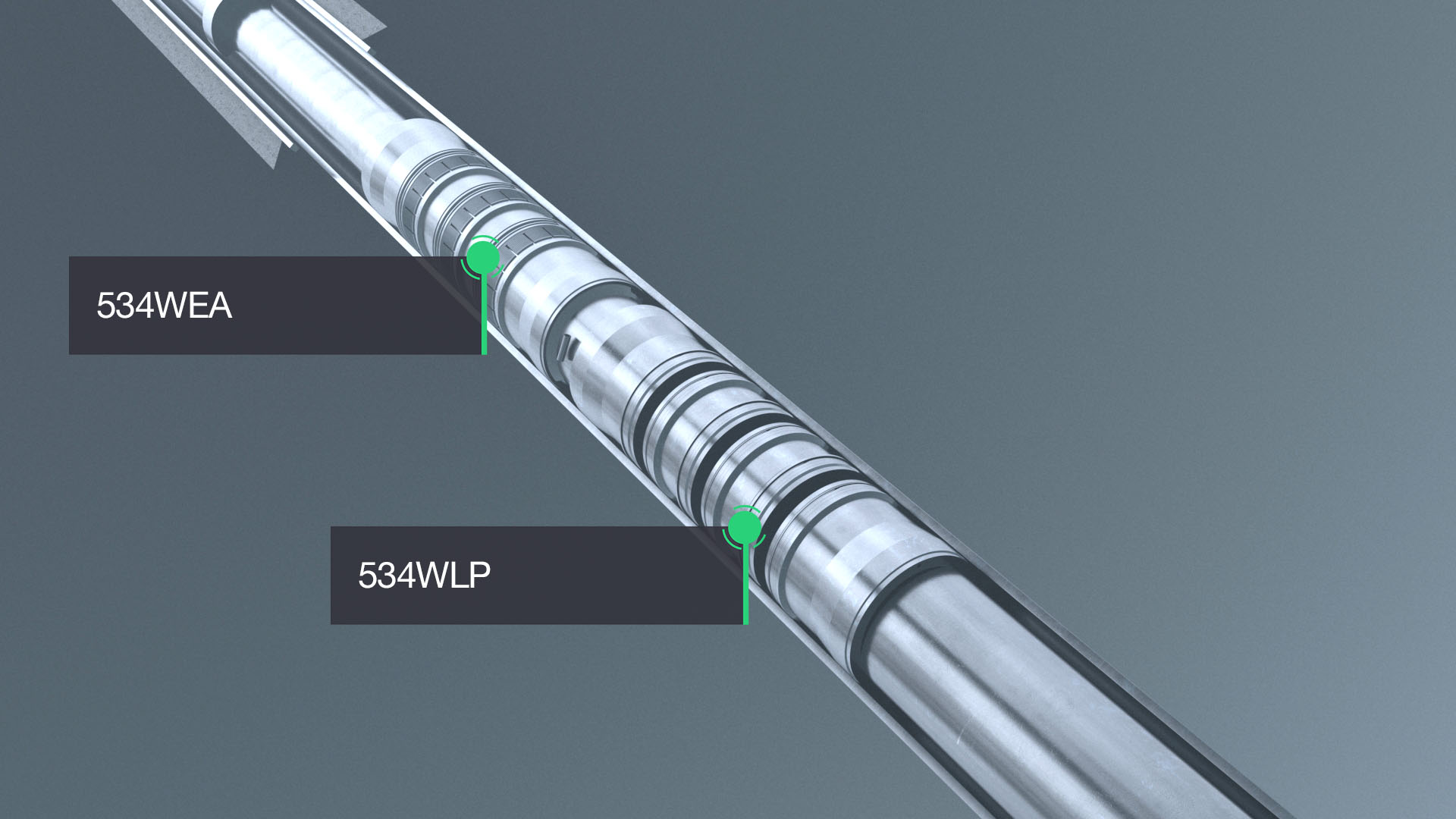

An innovative solution was developed by combining a 534 Welltec Expandable Anchor (WEA) with a 534 Welltec Light Packer (WLP®), providing life-of-well isolation of the damaged casing section, and anchoring the system in place regardless of different pressure scenarios.

The low burst rate of the casing limited the expansion pressure to 4,200 psi (80% of burst). As such, the WEA and WLP products were re-engineered and qualified to expand at a lower pressure compared to standard products. The system was qualified in accordance with ISO14310 V3, and API9LH standards.

The minimal running OD of the WLP and WEA allowed safe transit through the 6 5/8” casing, drifted to 5.75” while maintaining full bore of the 4 ½” scab liner.

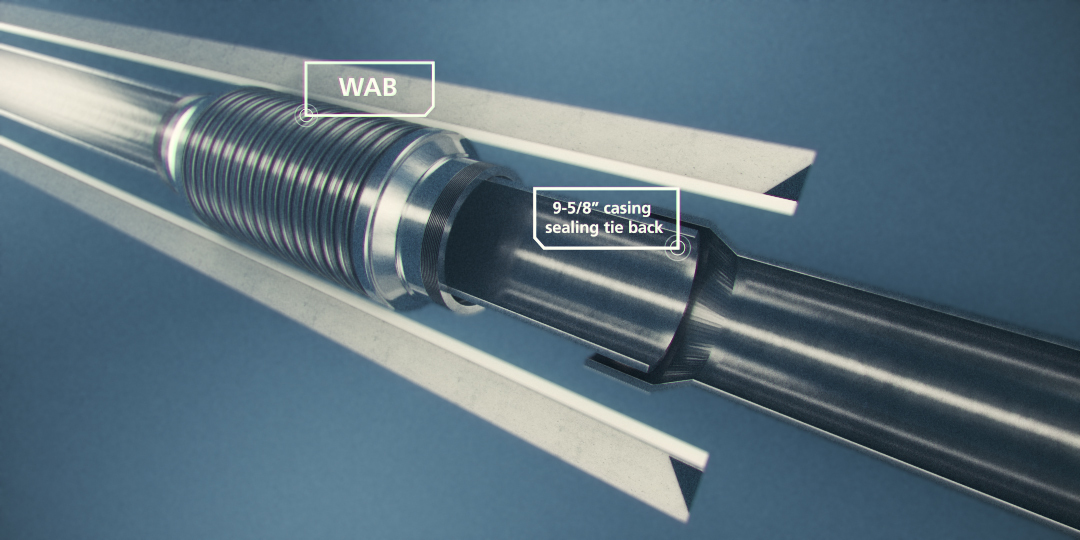

The assembly was run on the 4 ½” tie-back and landed in the wellhead. A Retrievable Test-Treat-Squeeze (RTTS) was run on the 2 7/8” workstring and set within the newly installed 4 ½” casing, below the WLP/WEA assembly.

Surface pressure was applied down the annulus between the 2 7/8” workstring and the 4 ½” ID, and both products expanded quickly, under full surface control.

A plug was set within the 4 ½” liner and a positive pressure test was achieved on the WLP.

Achievements

The client’s primary objectives to re-instate well integrity and isolate the corroded section of the 6-5/8” casing were achieved quickly and efficiently, restoring production with an assured and cost-effective solution.

Utilizing new technology from Welltec, the client was able to avoid the significant cost and risk associated with remedial cement alternatives.

Within approximately a two-month timeframe, Welltec was able to re-engineer and qualify the completion products for job-specific requirements (reduced expansion pressure), also completing the first-ever global deployment of a WEA product.

The damaged casing was successfully isolated, and the completion now features a re-entry guide for future interventions.

Well schematics