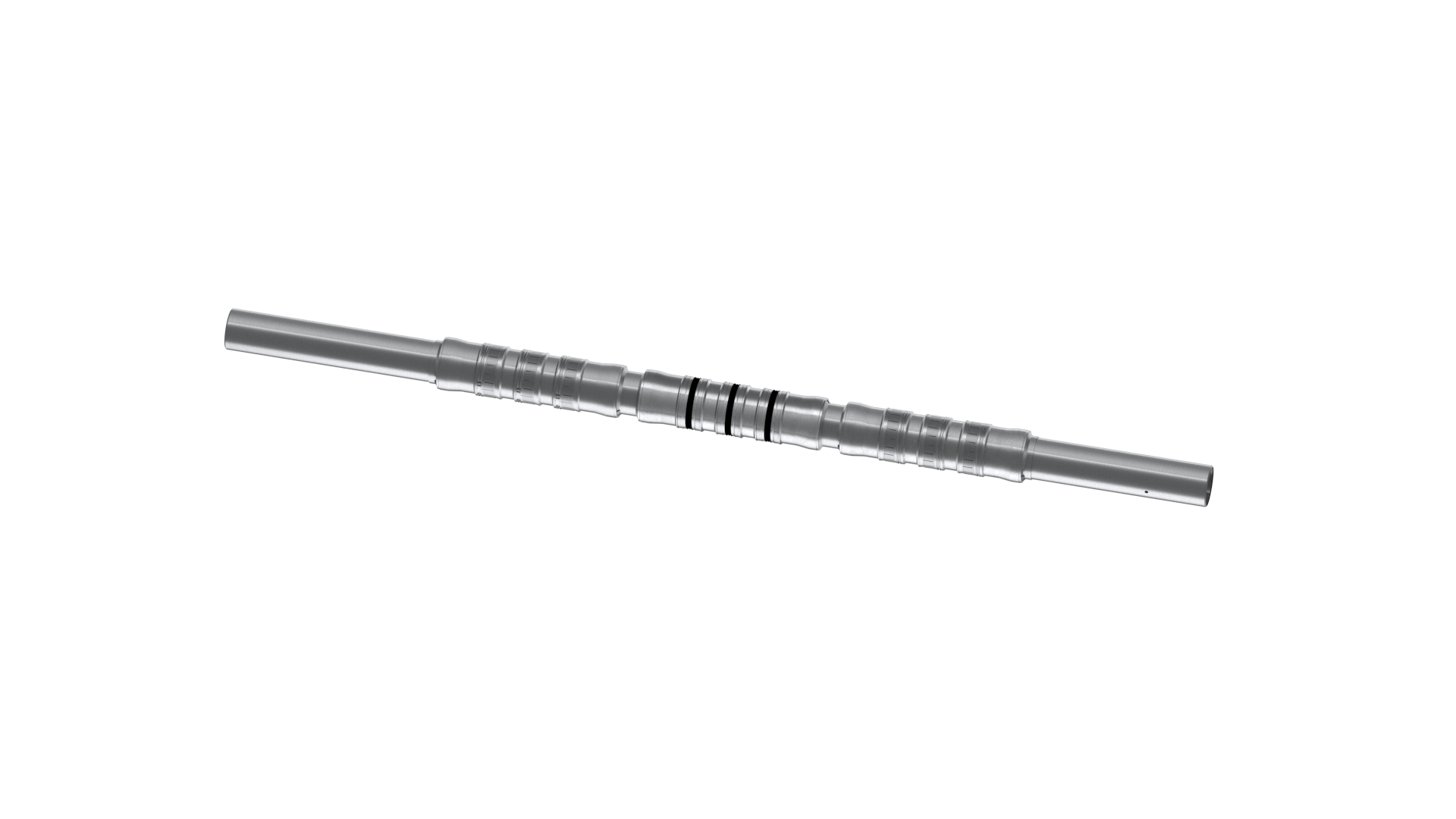

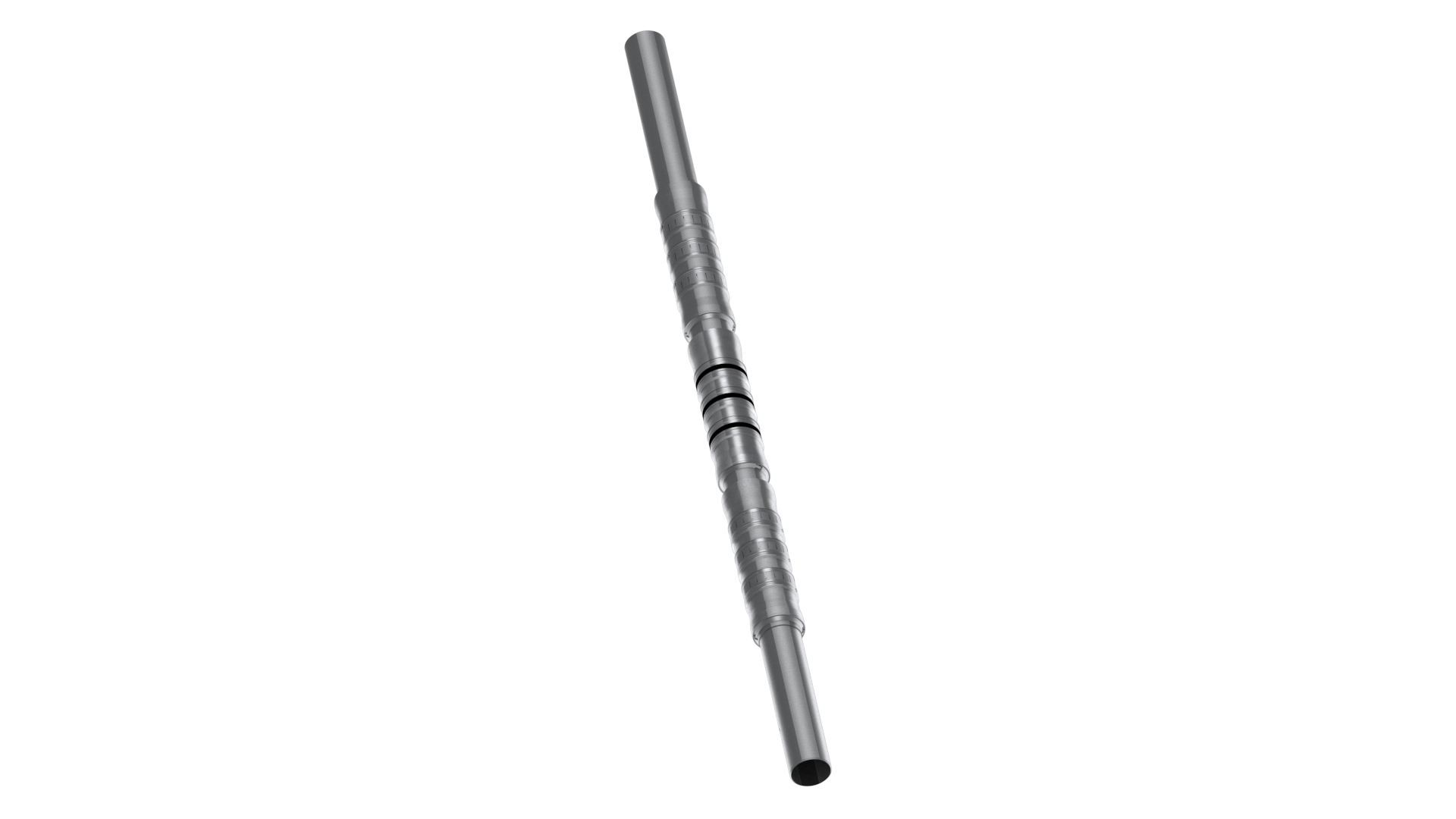

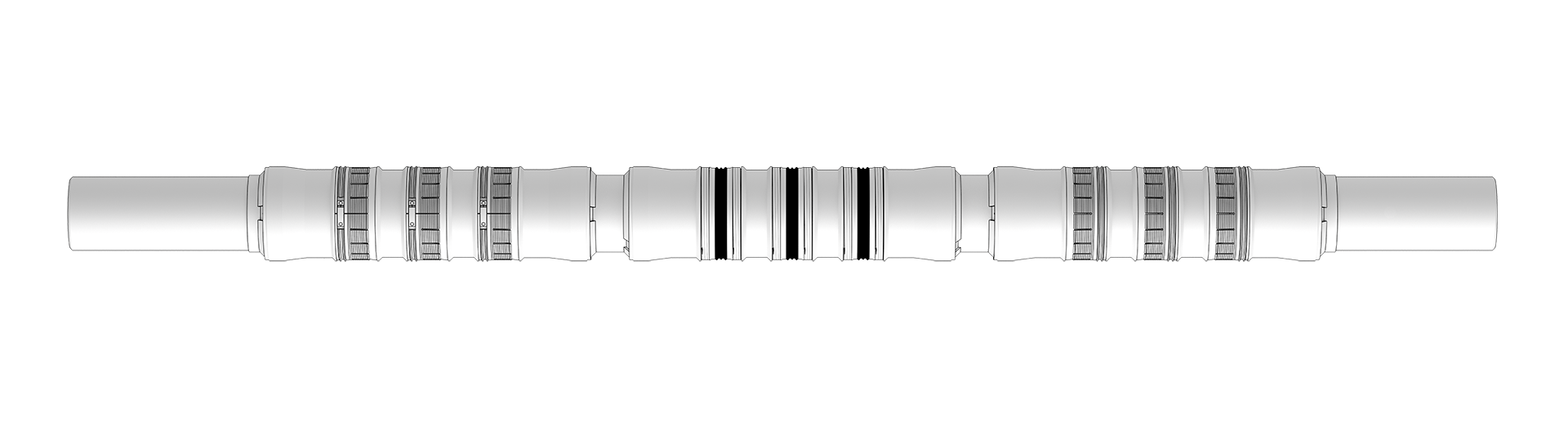

Overview

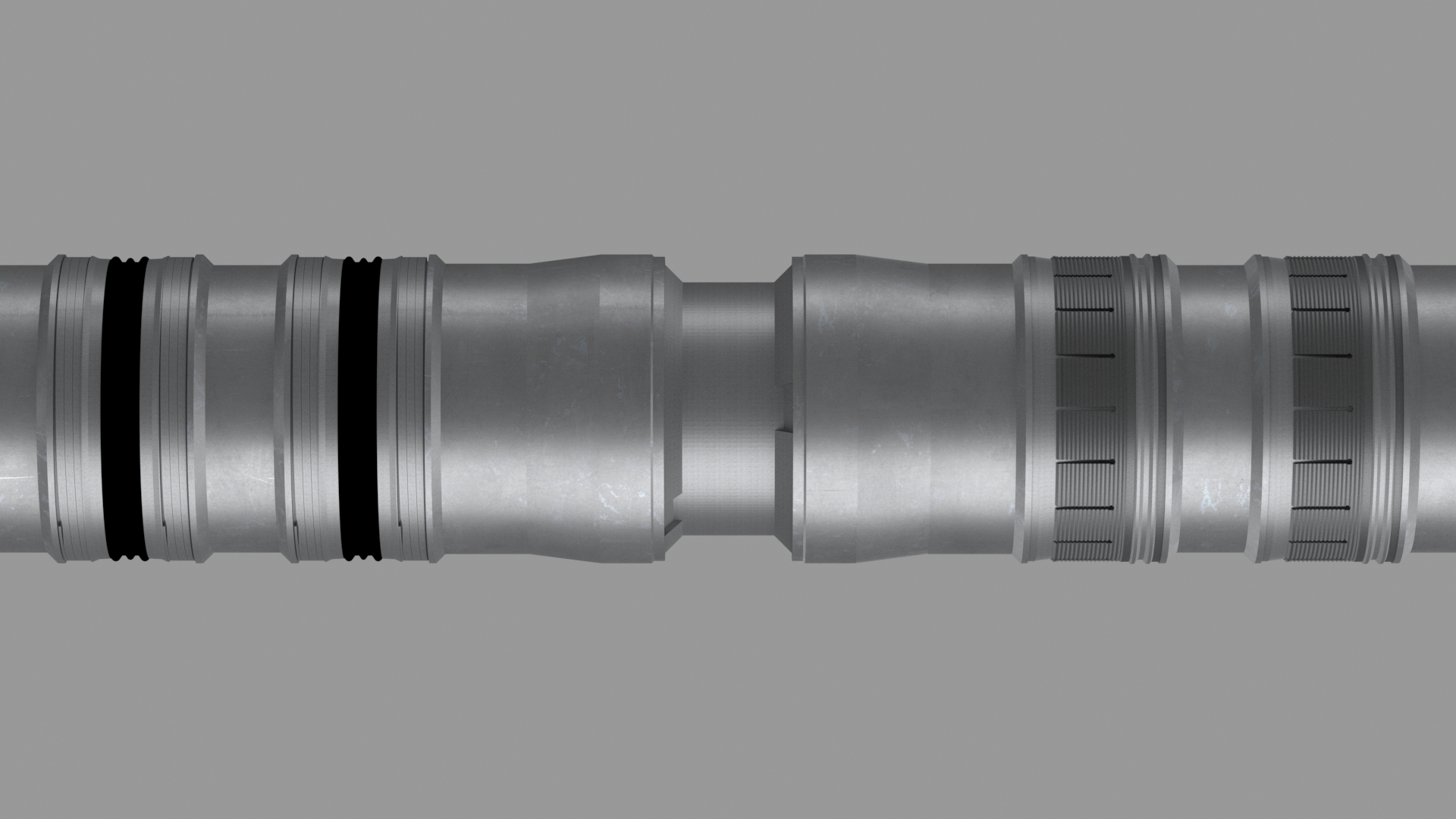

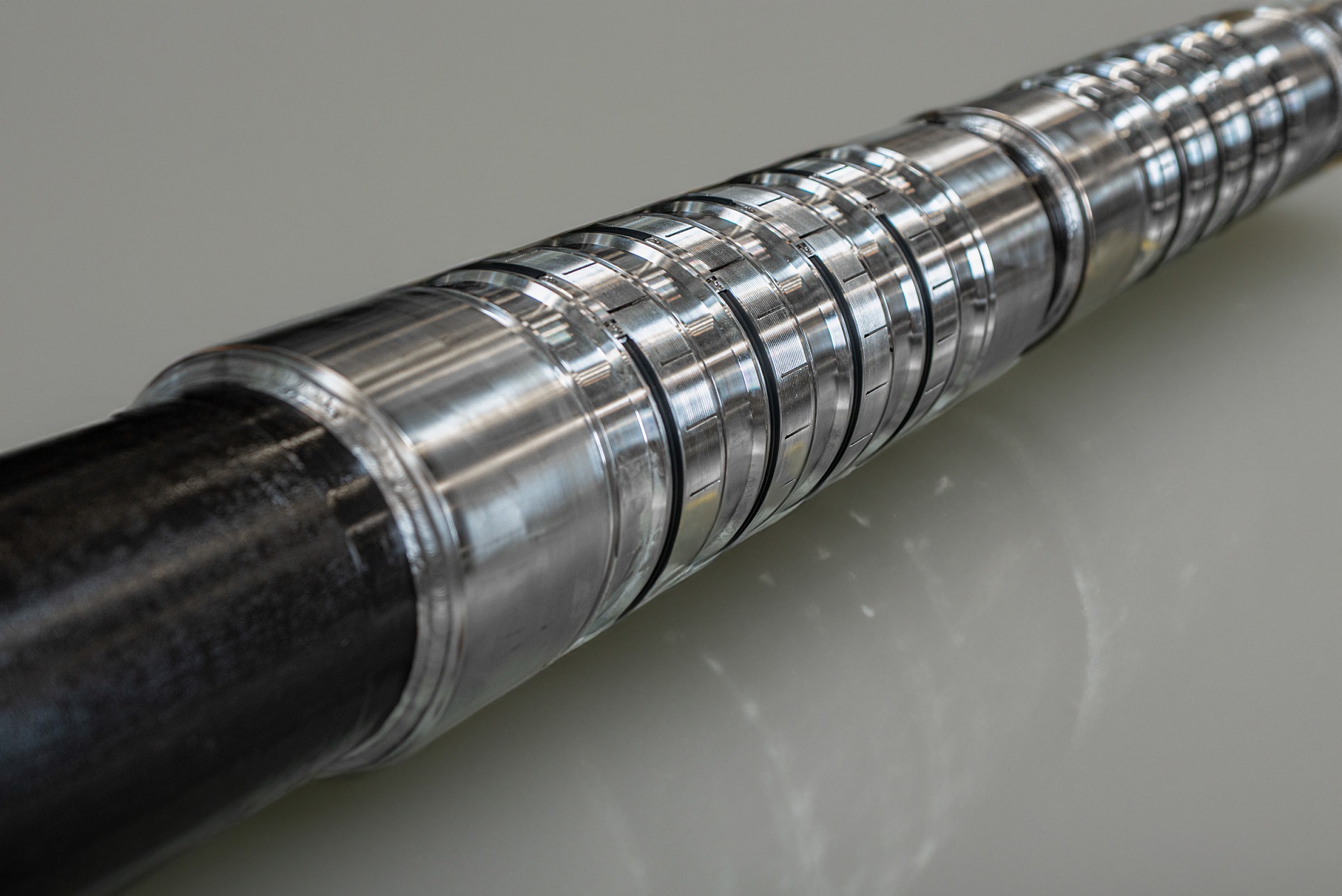

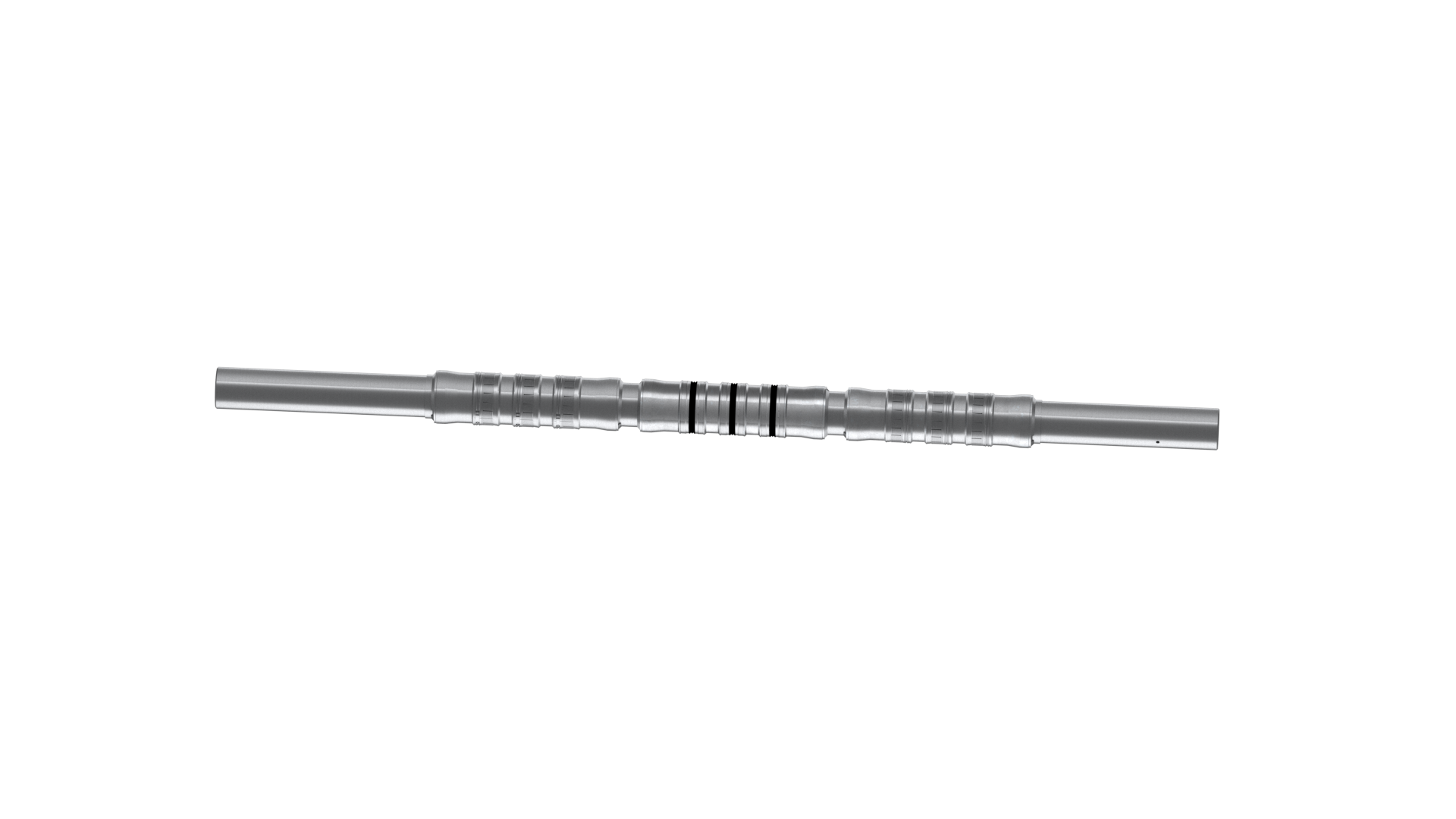

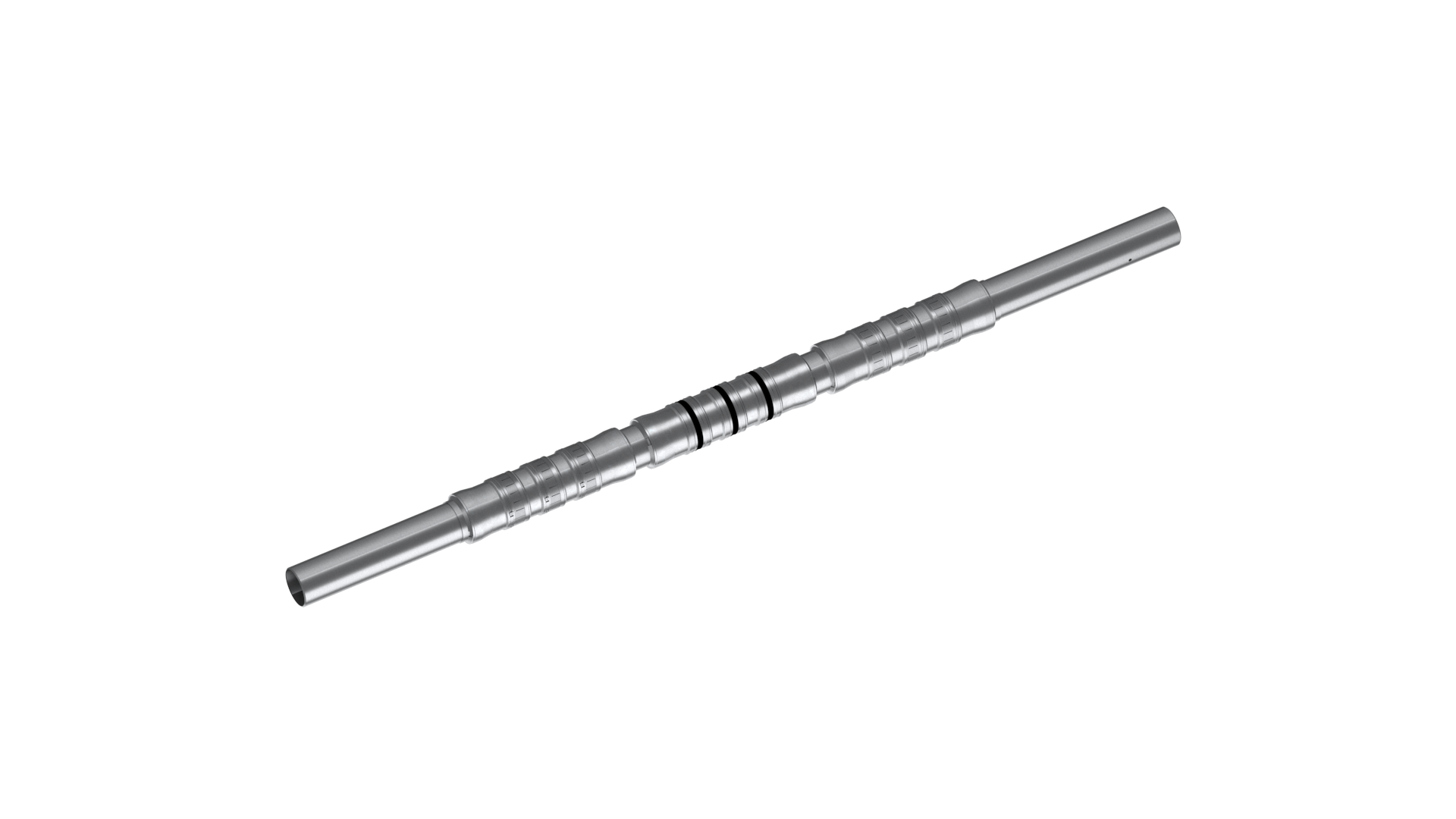

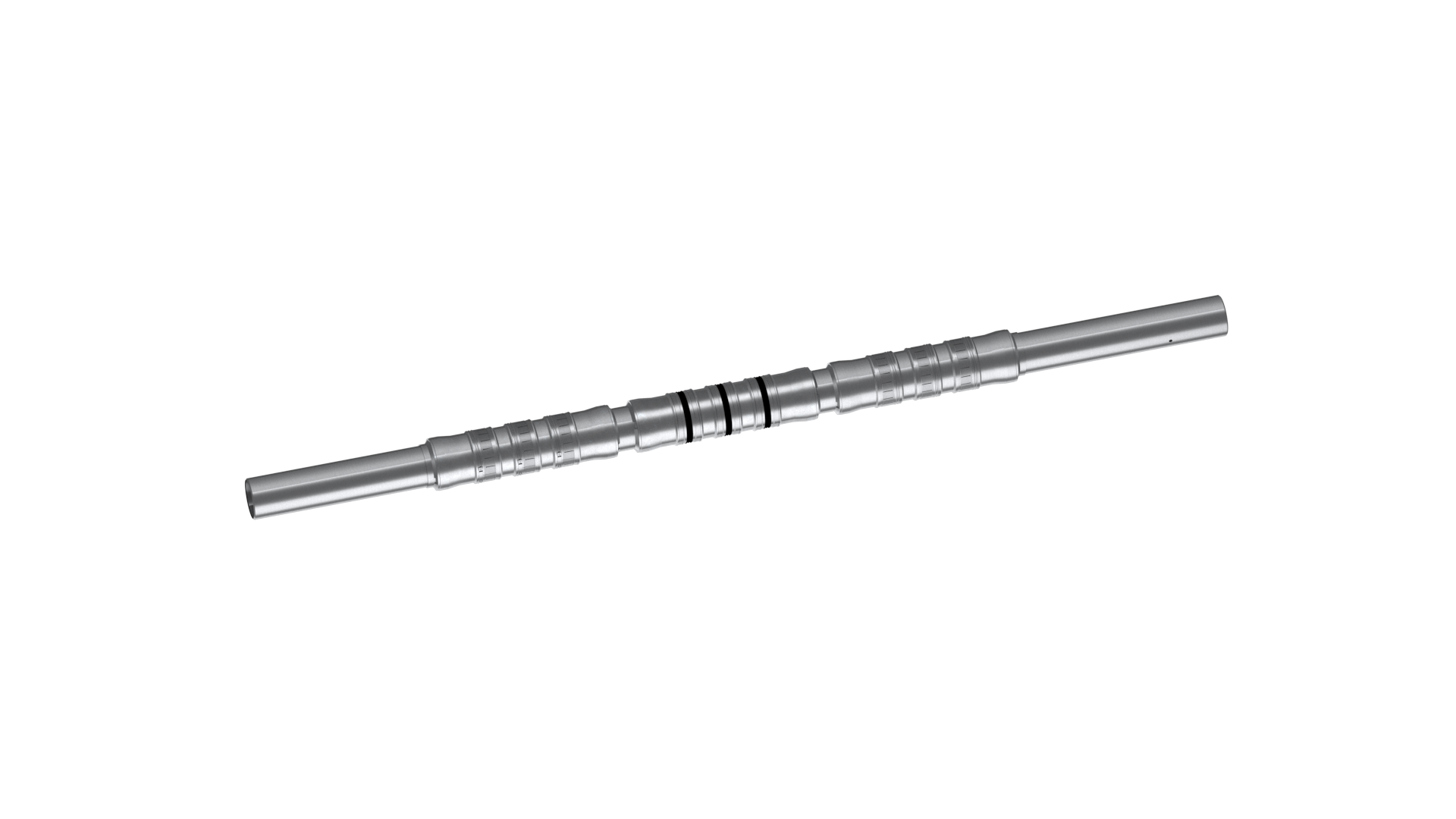

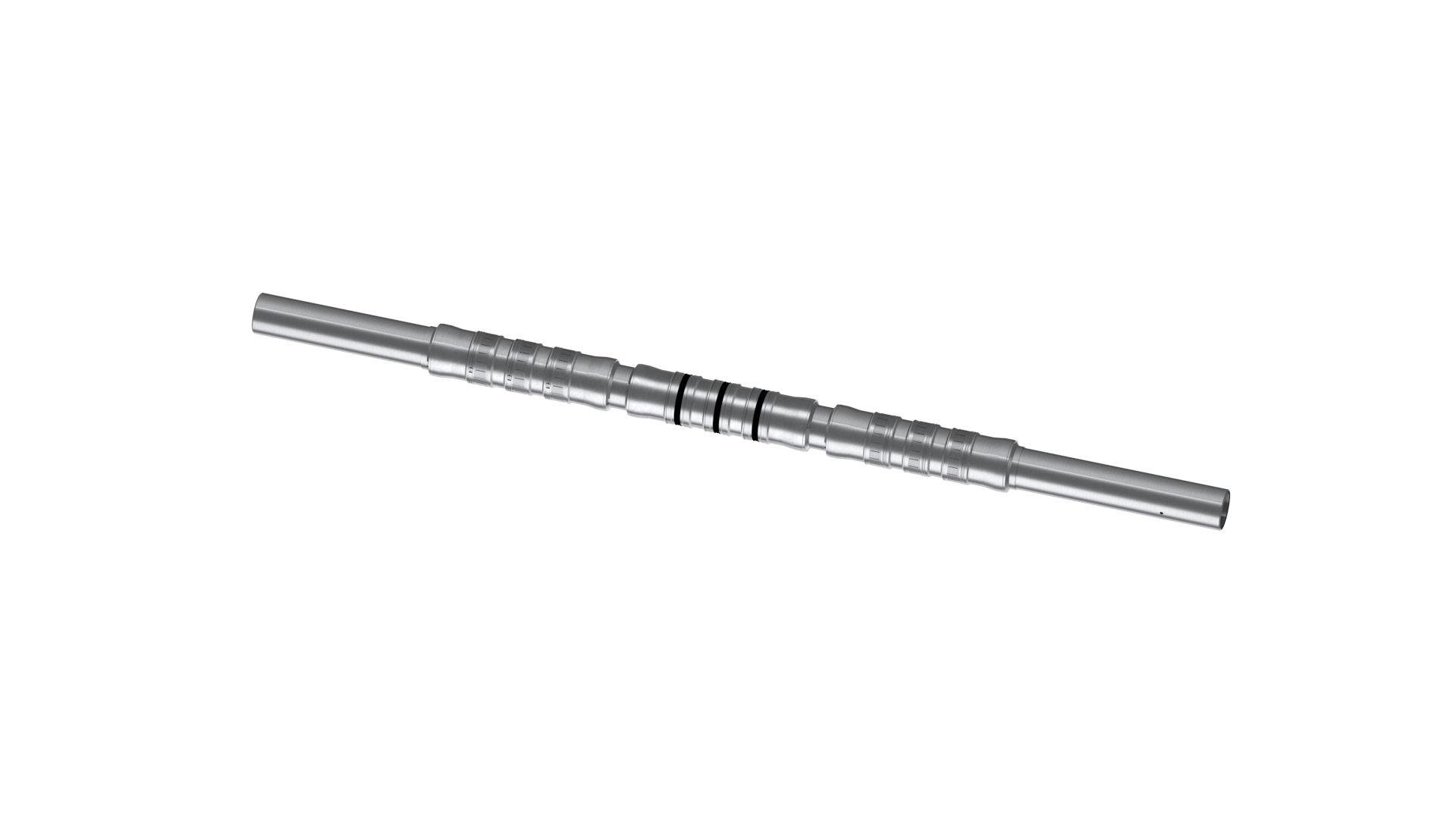

The WEA is a single-piece machined sleeve, fully welded to a base pipe. The main anchor section is a machined slip that is mounted over the expansion sleeve.

The functionality and characteristics of the expansion sleeve are similar to that of Welltec’s metal expandable packer range. As the sleeve expands, the anchor rings engage with and grip the liner/casing ID. As the load is applied, the grip is increased, and increased load anchoring can be provided via additional sleeve assemblies.

The WEA range is fully compatible with Welltec® Metal Expandable Packers and WIV® technologies.

* Custom specifications and control line feedthrough options available on request.