Well Cutter® performs critical cut

- Well type Water injector

- Pressure 5,076 psi @ 11,460 ft

- Temperature 215°F @ 11,460 ft

Background

An operator in Canada attempted to set a bridge plug below the Polished Bore Receptacle (PBR) during abandonment operations on a water injector to isolate the reservoir. These steps were being taken prior to drilling a sidetrack. While setting the plug, wireline was correlating and pulled up out of the tailpipe but could not place the plug back into the tailpipe to be set. The operator then decided to set the bridge plug higher up in the completion.

Since the plug was set in the tubing, everything below the plug needed to stay in place. Without the bridge plug in its proper place, the tubing potentially could be pulled out of the PBR, leaving no barrier to the formation – as such, the 7” tubing needed to be cut. The rig would not be able to provide tension or confirm the cut through pulling, so the operator required multiple ways to confirm the cut before pulling the tubing.

Welltec® had recently completed a cutting job on another well, and with the Well Cutter® still locally available, Welltec quickly mobilized tools to the rig.

Operation

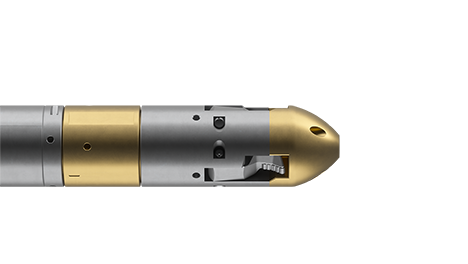

During the operation, Welltec provided a casing collar locator and gamma ray tools that worked with the wireline provider’s data to correlate depth. Once at depth, cutting commenced and lasted for approximately 20 minutes before the Surface Readout (SRO) data indicated that the Well Cutter had cut past the Outer Diameter (OD) of the tubing.

After pulling the tools out of hole, Welltec confirmed the cut by inspecting the mechanical indicator on the Well Cutter. The indicator confirmed the SRO data, in that the Well Cutter had cut beyond the OD of the tubing.

Achievements

Welltec delivered a successful cutting solution within hours of the client’s call. Initially, the operator was unsure if the tubing would be in tension or compression but knew of the Well Cutter’s capabilities to cut in a variety of environments.

Additionally, with the bridge plug set in the completion, the cut’s location and effectiveness was essential. If the tubing was pulled with an incomplete cut or cut at the wrong location, the formation could be exposed – a health and safety risk as well as a costly mistake. Welltec’s solution provided the client with greater peace of mind by providing SRO data as well as a mechanical indicator to confirm the cut.

With confidence in the tools and data, the client was able to pull the tubing successfully after the cut and complete abandonment operations.