Well Cutter® Performs Reliable Tubing Cut in HPHT Environment in USA

- Well type: Water injector

- Water depth: 7200 ft (2195 m)

- Cutting depth: 25,200 ft (7681 m)

- Pressure: 15990 psi (1103 bar)

- Temperature: 289˚F (143˚C)

Background

An operator in the Gulf of Mexico observed anomalies in a water injector after setting the production packer. After troubleshooting, the client identified a likely leak in the production casing.

Testing revealed a potential connection to the 12-1/4” shoe, and an acoustic noise log performed throughout the production tubing verified a leak at the production liner top packer. Unfortunately, this issue indicated that the production tubing needed to be removed to remediate the liner top leak.

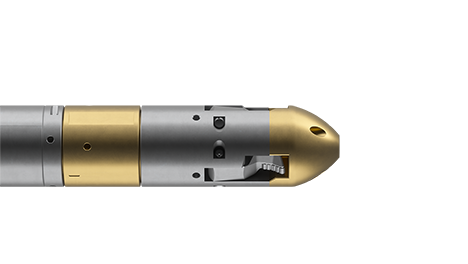

Welltec® was the client’s first choice to make the cut. The Gulf of Mexico has many high-pressure, high-temperature (HPHT) wells with maximum temperatures over 350˚F (177˚C) and maximum pressures over 15,000 psi (1034 bar). The HT Well Cutter® was developed specifically for this kind of work in these HPHT environments. Additionally, the client had worked with Welltec multiple times in the past, and the Well Cutter had a 100% success rate.

Operation

The leak was discovered in a new completion, and the operator began planning for remediation work in late January.

The Well Cutter’s precision cutting was desired in this situation to solve the issue and bring the well online as soon as possible.

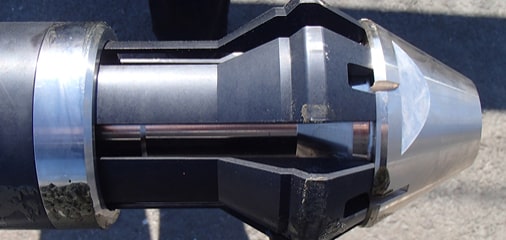

Welltec mobilized to the drillship in early February and set up to run the operation on e-line. The tool was run in hole, and the Well Cutter performed the cut successfully on the first run. The clean, beveled cut made retrieving the production tubing an easy task.

Achievements

With the rig spread at $1 million USD, the client needed to limit the time the rig was nonfunctional.

Alternative cutting options are simply not as reliable, and, in most cases, carry additional risks. Explosive cutters especially increase risk to personnel, equipment, the well, and the environment, all while increasing the likelihood of imprecise cuts that leave retrieval difficult because of poor quality.

The HT Well Cutter was designed to withstand the extreme HPHT environment of this well while delivering the ability to cut under compression without explosives and leave a clean, beveled shape for retrieval. The success of this e-line operation saved potential lost rig time and maintained the 100% success of the tool in such environments.