Well Miller mills FIV and restores access for Aker BP in the North Sea

- Well type: Producer

- Max. depth: 5,775 meters (operation)

- Max. pressure: 1,624 psi.

- Max. temp.: 101°C / 214°F

Background

Milling interventions can resolve downhole problems for a variety of restrictions, not just scale buildup. One such issue is downhole hardware becoming stuck or no longer functioning properly.

In early 2020, Aker BP experienced a significant increase in water cut from a horizontal producer.

Production logging tools found no scale problem, but the run did reveal a half-open formation isolation valve (FIV). An additional caliper log showed the FIV had a clean shifting profile, but, after a failed open-close operation, Aker BP decided to mill the valve to make further logging and water shut off possible.

Welltec® previously collaborated with Aker BP to perform systems testing for just such a scenario in 2018, so the client knew there would be no need for further testing. Aker BP contacted Welltec for help with the operation.

Operation

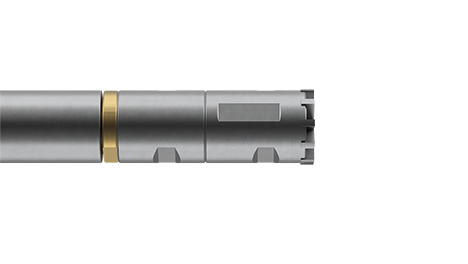

Welltec deployed a 318 Well Miller® conveyed by a 318 Well Tractor®. A 414 Well Cleaner® Power Suction Tool was also mobilized as a contingency for potentially fishing half-moon pieces. The Well Tractor would also facilitate plug setting.

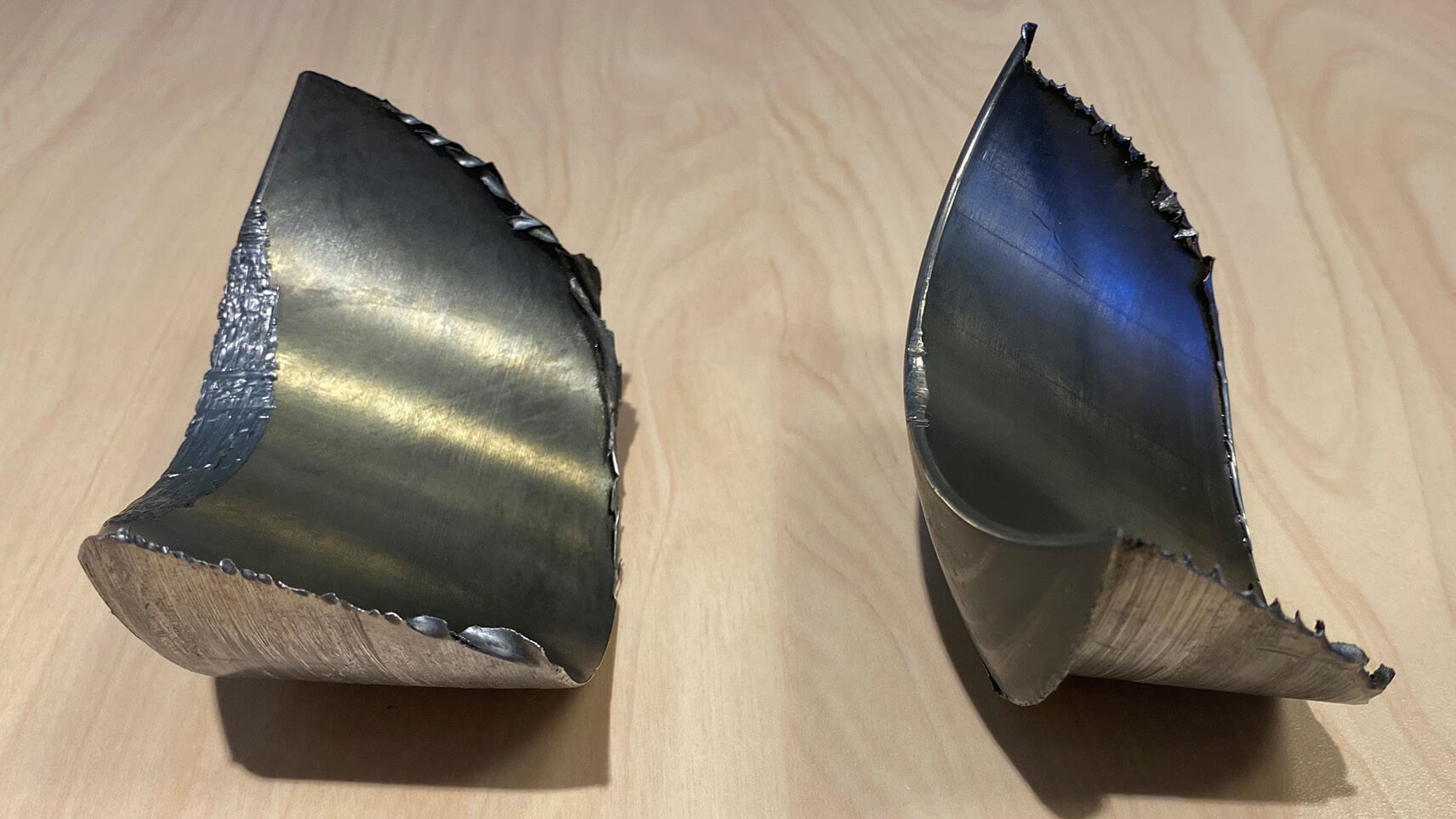

During the milling run, after tagging the FIV, Welltec milled the valve in two three-hour stages, pumping 50L of fluid every 30 minutes. Welltec milled the FIV and collected two half-moons in a single run.

Achievements

Welltec overcame this challenging operation and delivered access below the FIV for Aker BP.

Welltec completed the milling operation in just 8.5 hours, representing cost and time savings for the operator.