Well Miller ® CVF removes stellite-coated flow target operating from semi-submersible rig

- Well type: Producer (scheduled for P&A)

- Challenge: Downhole hardware

- Formation temperature: ~150°C

- Other: Flow Target Milling at sea level, not high temp

Background

TotalEnergies faced a significant challenge with a subsea Christmas tree in the North Sea, where downhole access was being blocked by a flow target lying in an upside-down position – this was also preventing the continuation of plug & abandonment activities.

The inner diameter going through the Christmas tree made it impossible to fish the stainless-steel flow target, which was also coated with an incredibly resistant layer of stellite. The only viable solution was to mill the flow target, but due to its highly resistant composition and the fact that the operation would need to be carried out from a semi-submersible rig, the situation demanded an incredibly accurate solution which could deliver fine levels of control and required weight on bit.

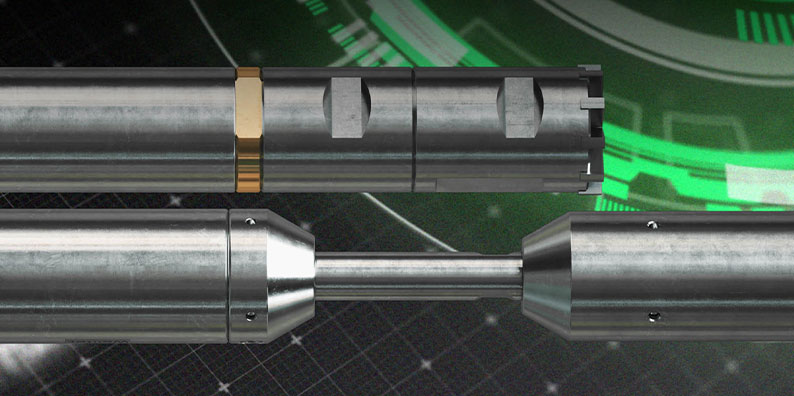

Welltec proposed an advanced hardware milling platform: Well Miller® CVF – Continuous Variable Force, offering industry-leading levels of precision and control. Due to the CVF platform’s ability to provide dynamic weight on bit with up to 5,000 lbs of force, the operation would be fully optimized against the challenging stellite material.

Operation

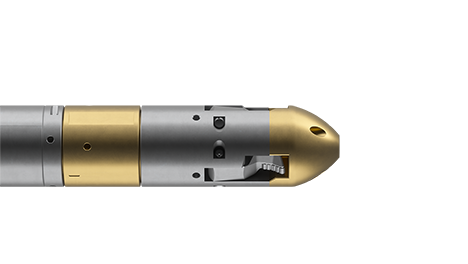

Before the operation, extensive testing led to the development of a custom-made two-stage bit (pilot and core) to ensure the retention of the milled-out coupon.

A specially designed sleeve was first set above the flow target, and this ensured that the Well Miller CVF engaged off-center, thus preventing the flow target from simply rotating upon contact. The stroker (actuation) section of the toolstring was anchored above the Christmas tree, with a shearable spacer bar between this and the mill bit, i.e. shearable across the subsea XT shear rams.

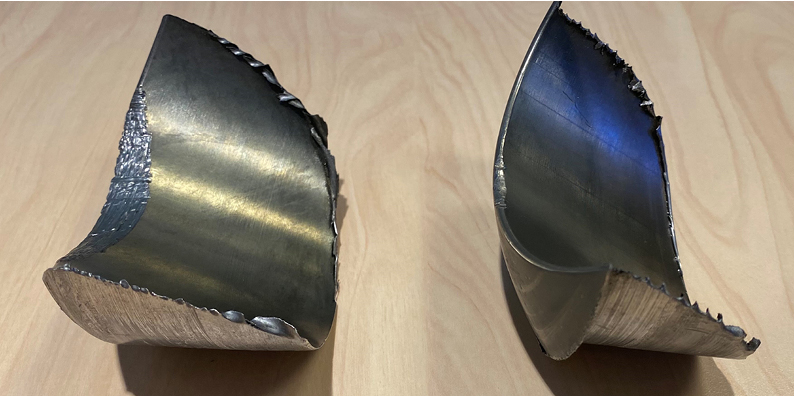

After the pilot section of the mill bit breached the flow target, weight on bit was increased in increments of 100 lbs, with Surface Readout (SRO) data enabling the precise monitoring of the stroker extension. Over two runs, a 4.4” hole was created through the flow target, and to the client’s considerable relief, the coupon was recovered back to surface. This allowed the setting of a 3” ID conduit sleeve to ensure safe access for subsequent runs into the well with a Deep-Set plug, after which a Well Cutter® 238 was utilized to cut the 4 ½” completion.

Achievements

Not only did TotalEnergies regain access to the well and therefore the ability to continue P&A operations, but savings in the region of $2 M (USD) were made by utilizing Welltec’s e-line deployed Well Miller CVF.

Rig-up time was just a few hours in comparison to entire shifts which would have been required for a coiled tubing solution, and the stellite-coated stainless steel flow target was milled in ~10hrs, with the milled coupon recovered to surface.

Utilizing the controlled force, accurate piston reading and precise weight on bit provided by the Well Miller CVF platform, a 4.4” hole was milled through the flow target, whereas the only ballistic alternative that had shown any potential in prior testing would have created a much smaller 1” hole, whilst presenting additional safety challenges.

This highly successful operation is further testament to Welltec’s track record in advanced e-line milling.

Client feedback:

“...a great achievement in milling [the flow target] and gaining access.”

.