Removal of hydrate plug and wax keeps North Sea client on track

- Max. temperature 86°F / 30°C

- Max. pressure 1,885 psi

- Location Norway

Background

Rapid response and minimal set-up time are essential to clean-out operations, especially when unanticipated obstacles are preventing scheduled work from continuing.

Welltec® had mobilized to the Barents Sea to provide mechanical services and perform a punch and cut operation on behalf of a North Sea client, this would enable them to retrieve an existing upper completion in preparation for drilling and completion of a new lateral.

However, the discovery of a significant hydrate plug on the first pipe cutting run signaled the beginning of an extensive clean-out operation.

Welltec quickly mobilized its full range of Well Cleaner® tools to arrive on the rig within 24 hours:

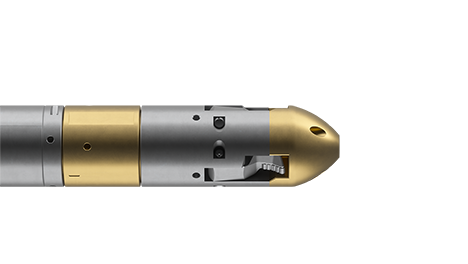

- Downhole Jetting Tool (DJT)

- Reverse Circulating Bit (RCB)

- Power Suction tool (PST) *already on site

Operation

The hydrate plug was met just below the tubing hanger at 441mMD. As the PST was already on site, this was set up to make two initial runs which removed a significant amount of hydrates to make 170 meters of progress, with wax also recovered into the bailer sections of the tool.

With the full range of Well Cleaner options available, the switch was made to the Downhole Jetting Tool (DJT). The DJT was not powered up until reaching hold-up depth.

The DJT delivered MEG/glycol solution to circulate and jet above the hydrate plug, dissolving and breaking up more debris to provide an additional 20 meters of progress.

Further debris (wax) was recovered into full bailer sections from an RCB run, followed by an additional DJT run gaining 10 meters and 216 meters respectively, to finally establish communication with the reservoir; a total depth of 226 meters had now been covered.

With injectivity established, RCB was run with customer continuously pumping base oil to help dissolve more wax. An additional 275m of progress was gained and the target depth was finally reached with 691 meters recovered.

With the remedial cleaning job complete, a Well Tractor® conveyed a ME plug, which was successfully set and tested.

The Welltec® Puncher and Well Cutter® combination was then deployed to mechanically create 10 perforations in the 5 ½” tubing - the cut itself taking just 10 minutes, respectively.

Achievements

When the original operation was unexpectedly transformed, Welltec was able to immediately call upon additional tools within its fleet, and seamlessly continue working.

Thanks to a rapid response and the deployment of multiple cleaning solutions within 24 hours, Welltec was able to minimize the delay to scheduled operations.

E-line conveyed tools were successfully applied to break down and extract significant amounts of debris, with the PST and RCBs integrated bailer sections recovering material to surface.

The planned punch and cut operation was performed quickly and efficiently – 10 perforations and a tubing cut in 10 minutes.