All-metal WAB restores production in high temperature geothermal well

- Well type Geothermal

- Temperature 482°F (250°C)

- Depth 7218 ft (2200 m)

Background

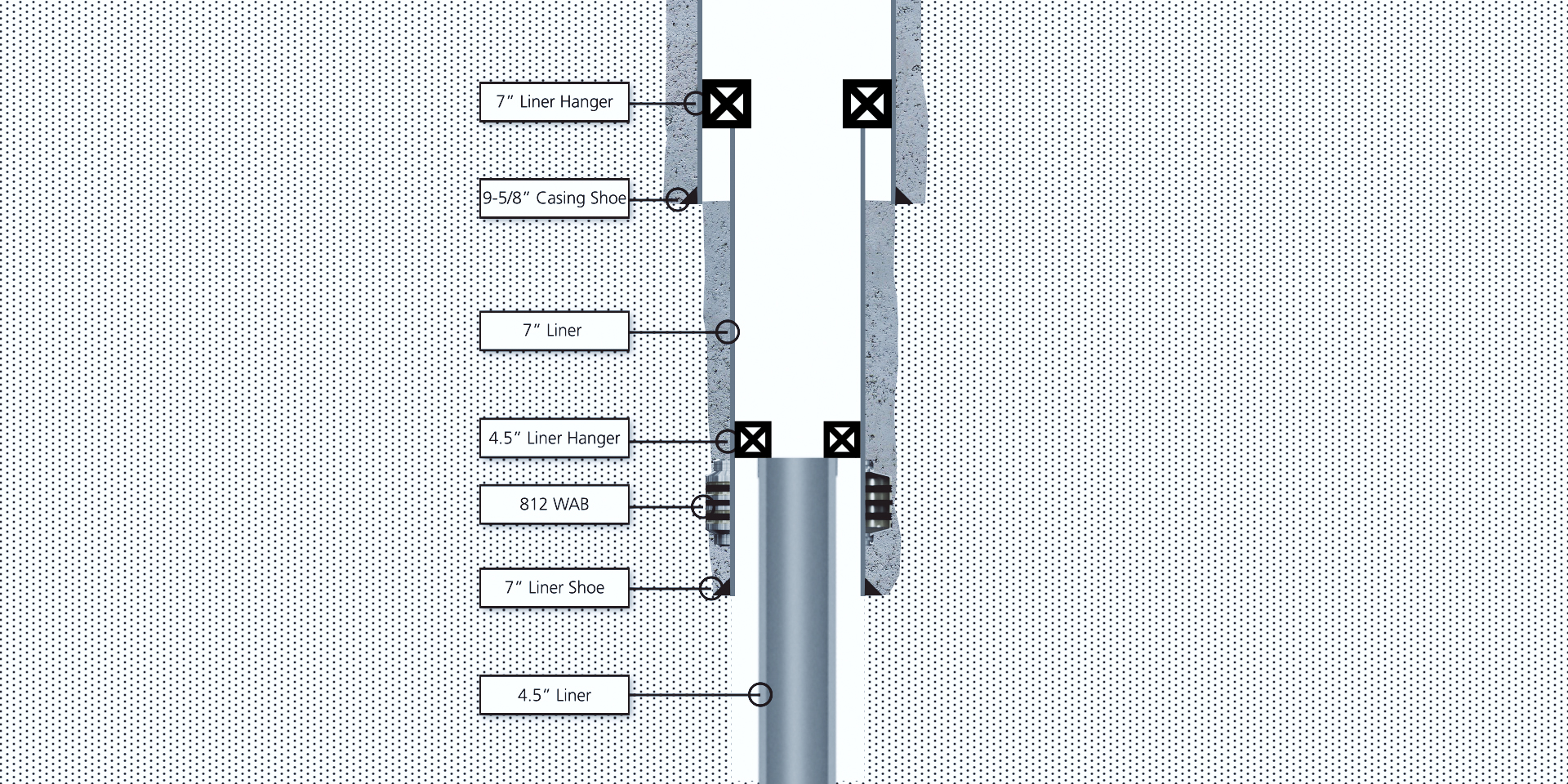

A client in Japan drilled a high temperature (HT) geothermal well that produced hot steam up to 482°F (250°C). However, the well encountered cold water invasion during production from fault-and-loss zones on top of a section of the hot rock. A side-track was planned to land 7” casing into the fault-and-loss zone at a depth of approximately 6234 ft (1900 m) to isolate the cold-water zones. Squashing the well with cold water could cool it to 302°F (150°C).

The well contains slight deviation and has a total depth of 7218 ft (2200 m). Pressures within the fault-and-loss zones were minimal. The well was shut-in until a solution could be determined.

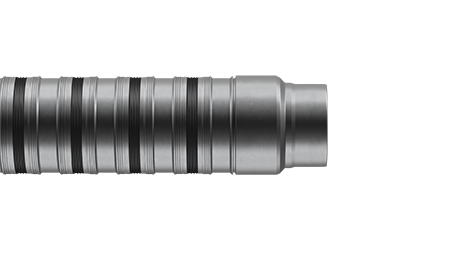

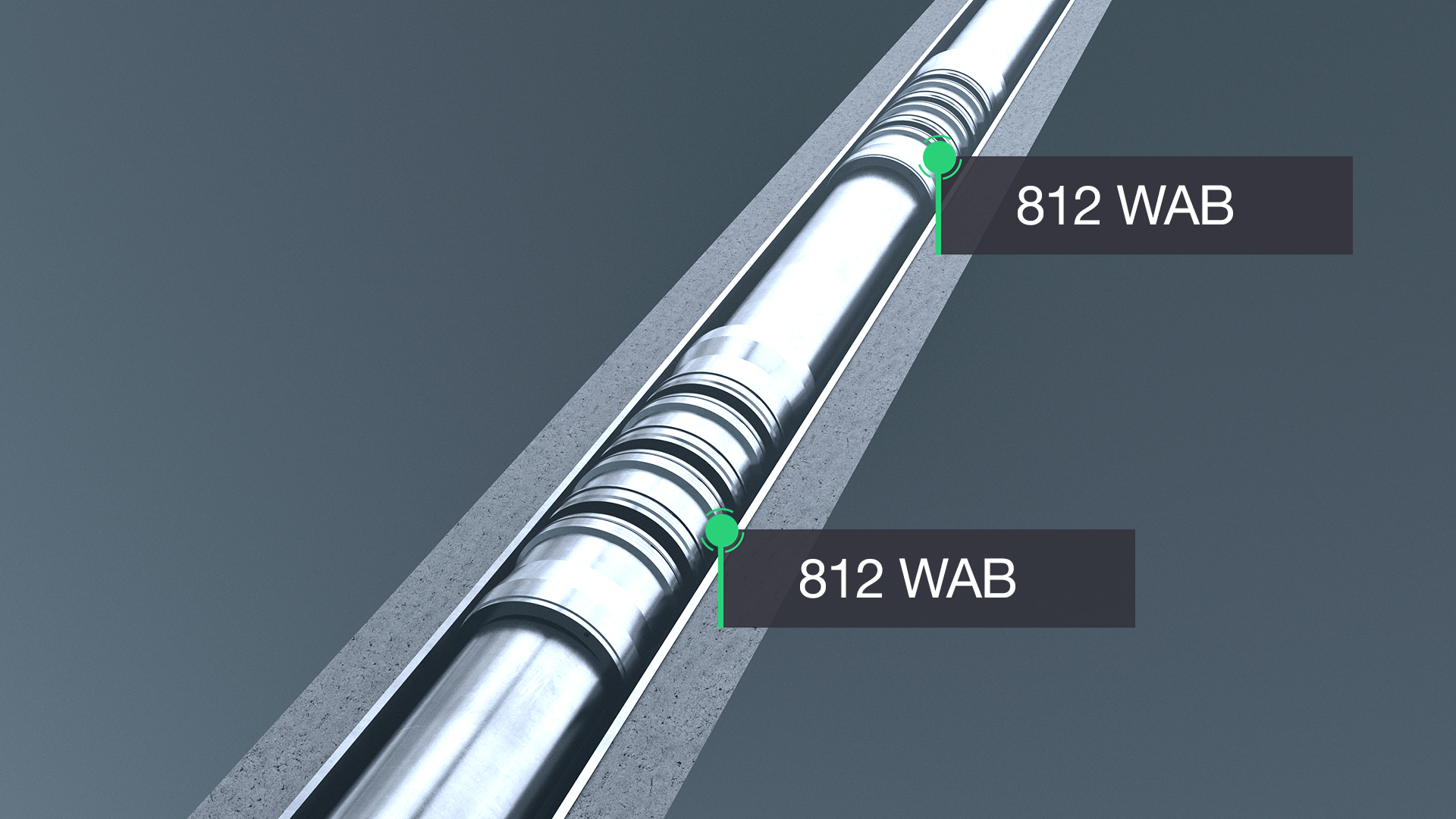

As a solution, Welltec® suggested using the Welltec Annular Barrier (WAB®) in conjunction with cement on the 7” liner section to isolate the fault-and-loss zones that produce cold water. The WAB maximizes sealing length with full-metal seals and the sleeve while minimizing outer diameter (OD), providing a solution suitable for a HT geothermal well.

Operation

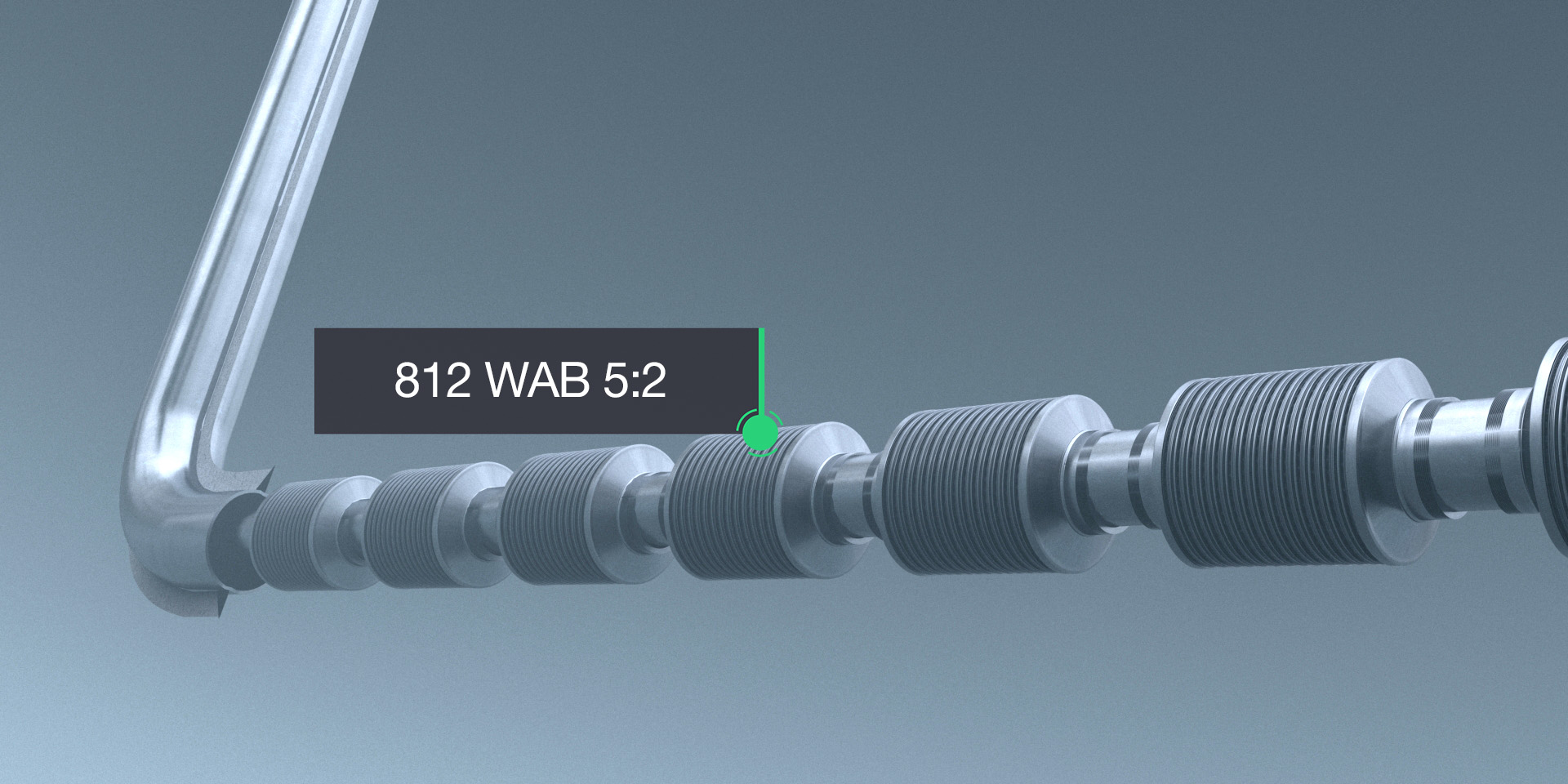

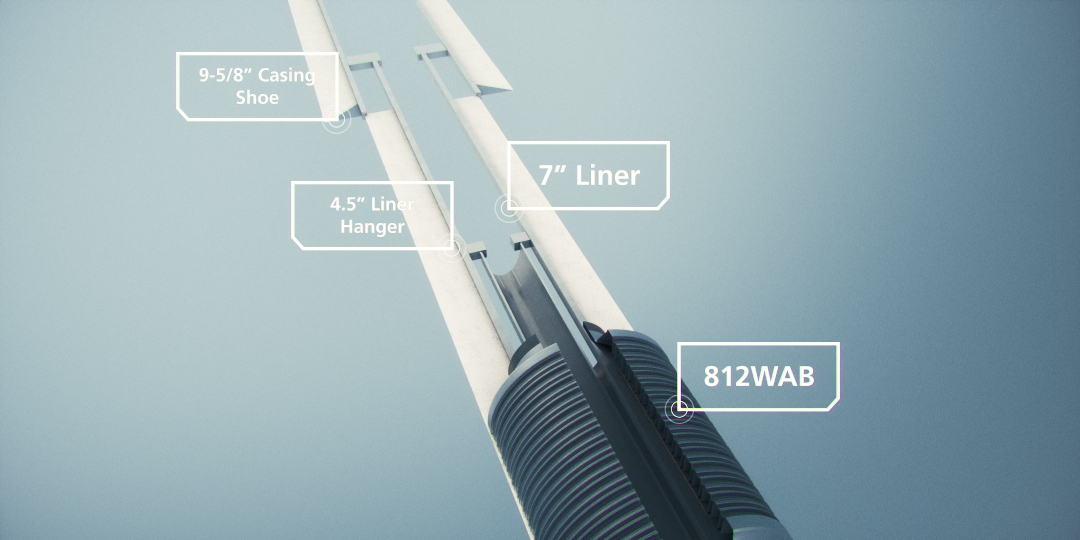

The 812WAB HT, with a run-in-hole OD of 8.2”, can expand out to 10”, which is compatible with the possible wash-out hole on the new side-track section. Additionally, the WAB’s design could be integrated with the client’s cementing program without requiring significant modification.

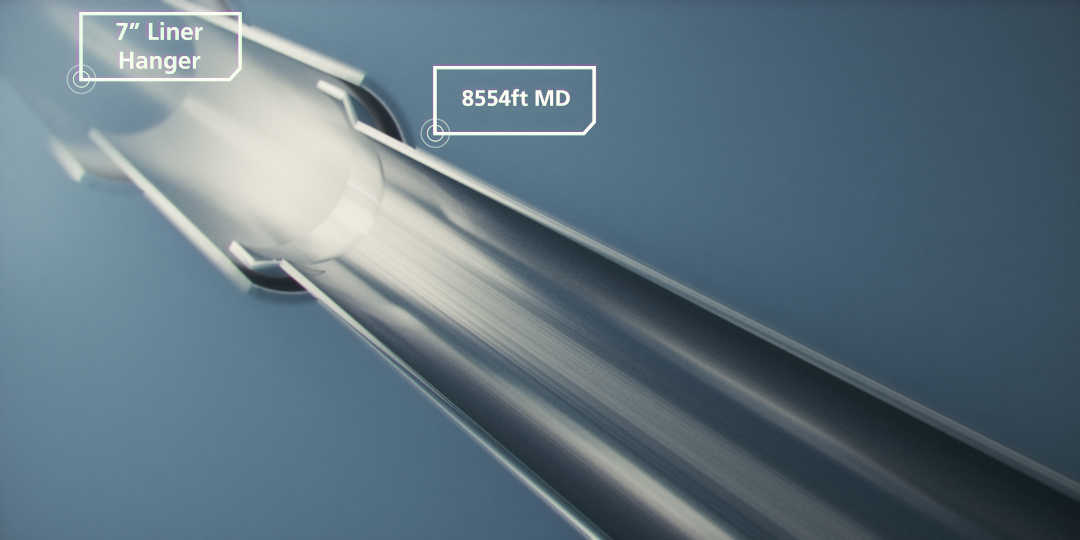

At the well, the 7” liner was deployed with the 812WAB5:2 HT at 6398 ft (1950 m) to isolate the fault-and-loss zones close to the toe of the 7” liner. Upon reaching depth, the liner hanger slip was set, and the cementing job was performed. Once the plug landed successfully, pressure was applied to expand the WAB in the wet cement.

Achievements

Even in the hot well environment, the HT rating of the all-metal WAB ensured that operations throughout ran smoothly. The WABs deployed successfully through the HT condition and mill window. Integration with the existing liner design and cementing operation was seamless. A cement bond log confirmed WAB expansion and showed effective isolation of the fault-and-loss zones.

The well has been brought back into production and produces hot steam up to 482°F (250°C). This successful operation was the first install of an all-metal WAB worldwide.