Case highlight

A client operating in Offshore Atlantic Canada was having challenges with successfully isolating high water saturation intervals within the reservoir using swell...

WAB® for Zonal Isolation

Extended reach, cementless lower completions via rotatable, metal expandable packers

To increase net present value of their assets, extended reach horizontal reservoir sections are becoming critical to operators looking to increase well productivity and maximize their ROI.

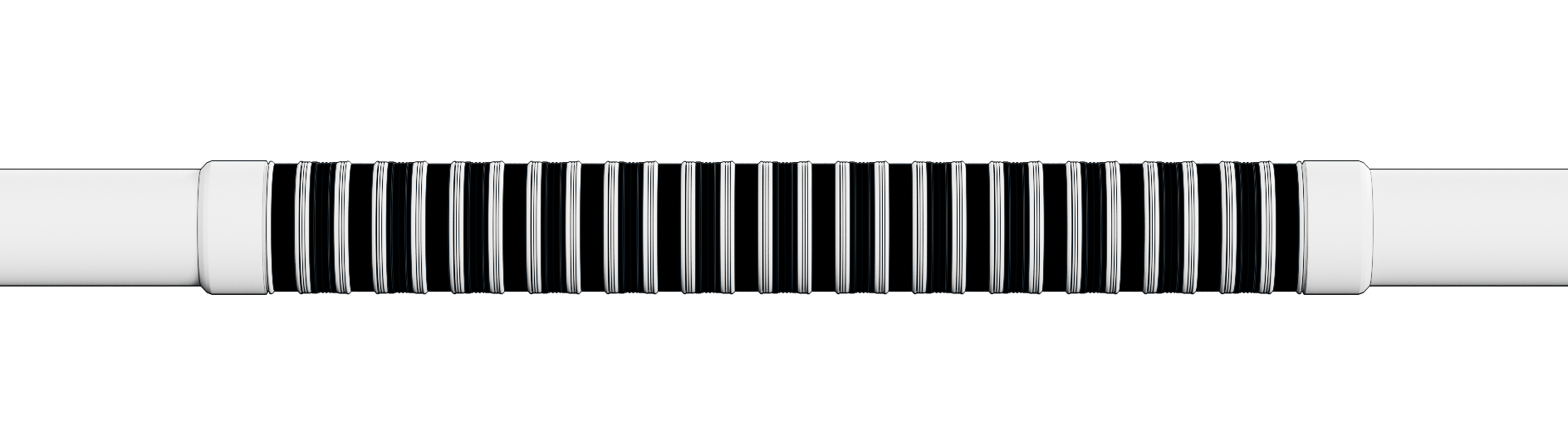

Extended reach lower completion design creates significant concerns over the ability to execute a conventional cement or perforated liner well design due to the high inclination nature of the reservoir section. This is due to the required ability, across these heterogeneous formations, to isolate unwanted water or gas inflow by isolating and compartmentalizing the reservoir. To achieve this it is critical to design the well with reliable isolation between lower completion and open hole without the need for cement.

A client operating in Offshore Atlantic Canada was having challenges with successfully isolating high water saturation intervals within the reservoir using swell...

A client desired zonal isolation within a horizontal well with an open-hole completion. The client chose the Welltec Annular Barrier (WAB)...

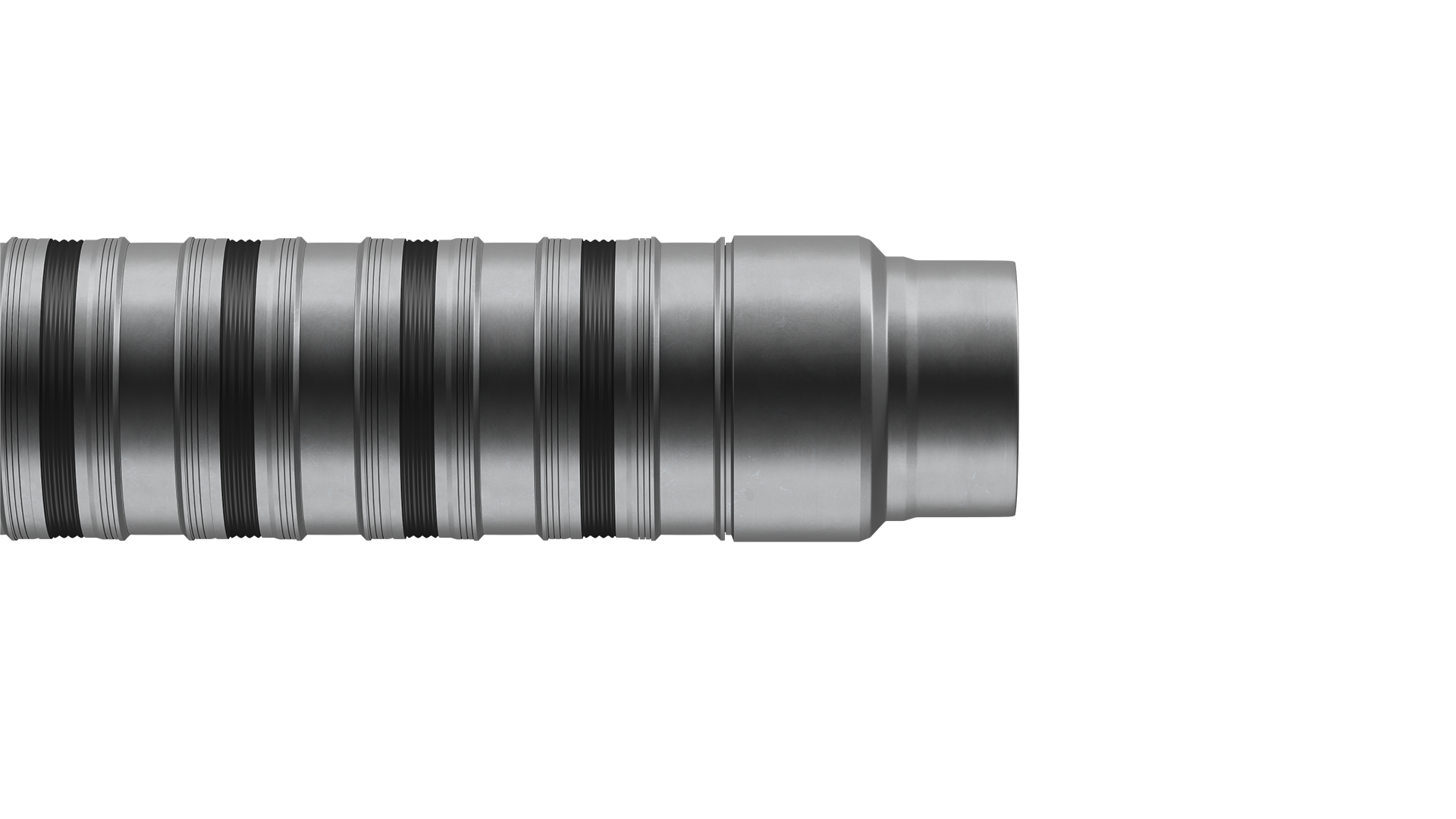

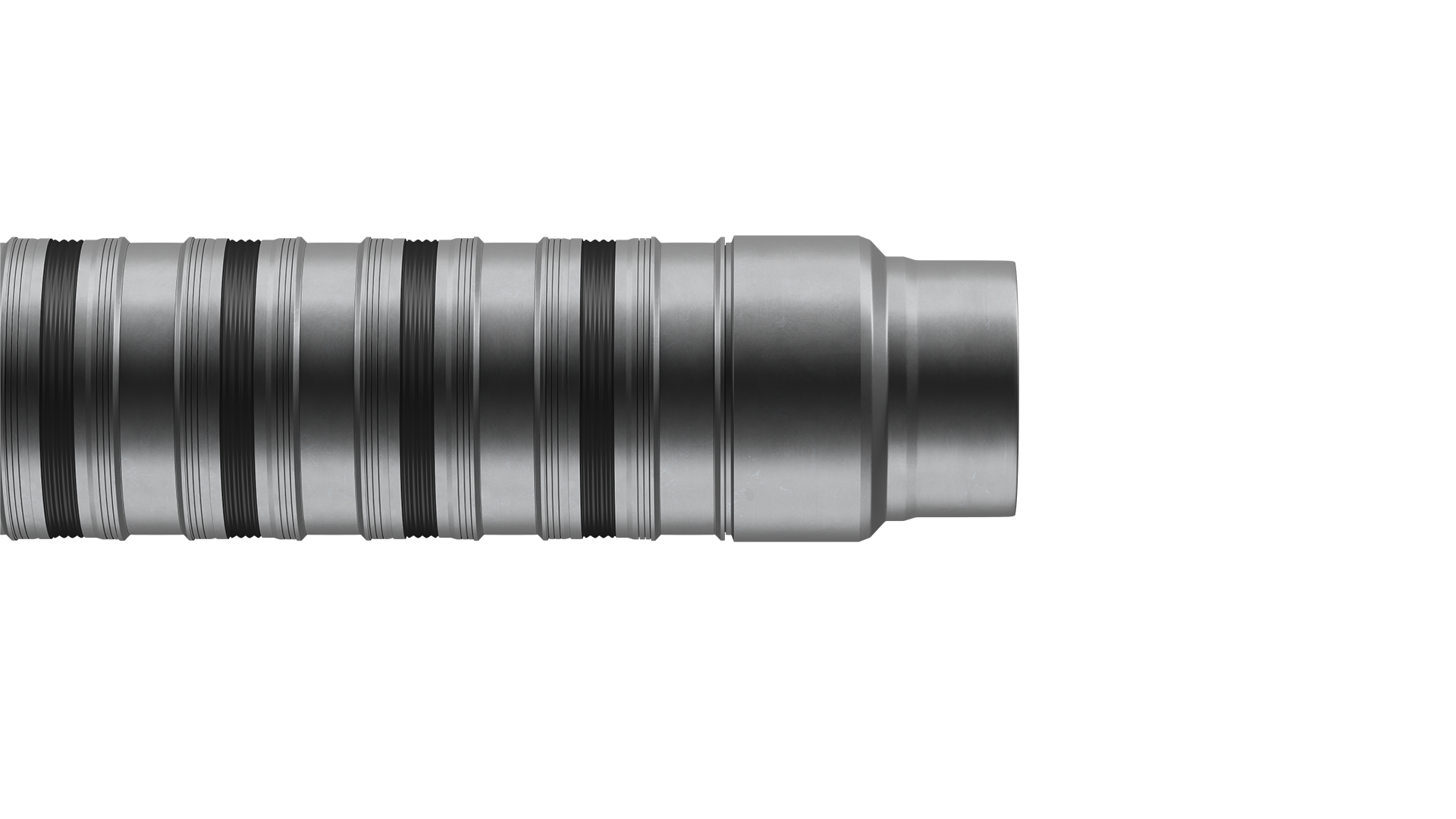

Our ISO 14310 rated, metal expandable WAB (Welltec Annular Barrier) for open hole zonal isolation, facilitates the ability to deploy ‘cementless’ extended reach, multi zone, horizontal, lower completions.

The WAB provides the on-demand, high pressure zonal isolation across varying borehole geometries unaffected by thermal changes in the wellbore, so often a problem in conventional open hole reservoir isolation.

| Expansion range | 5.75" 10.00” |

|---|---|

| Min. running OD | 5.56” 8.240” |

| Max. working pressure | 5,000 psi 15,000 psi |

| Constant element ΔP across expansion range | 5,000 psi >15,000 psi |

| Base pipe range | 4-1/2” 7” |

| Standard element length | 7.2 ft |

| Temperature | 500°F |

| ISO14310 Standard | Up to V0 |

| ID | Full bore (as per base pipe) |