Reservoir management

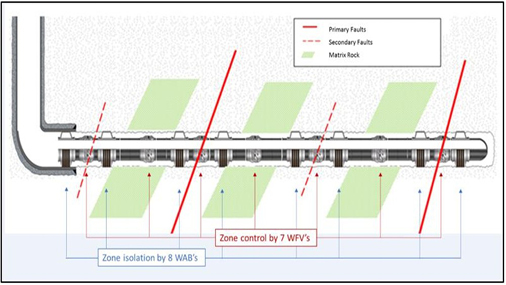

Oil and gas reservoirs with a high degree of rock heterogeneity created through complex depositional environments, diagenetic or structural overprint, demand well completion solutions enabling response to changing reservoir conditions over the life of well to maintain maximum well delivery.