Maximizing workover operation efficiency in Africa

- Type of well: Oil producer

- Depth: 3200 m / ~ 10,500 ft

- Pressure: 3200 psi

- Temperature: 135°C / 275°F

Background

An operator in central Africa needed to perform a workover on an oil producer that involved pipe recovery. Prior to this operation, though, the operator needed to take preliminary steps to establish circulation and facilitate retrieval of the tubing.

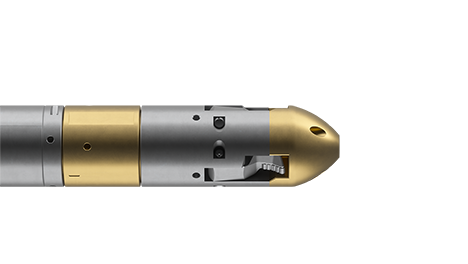

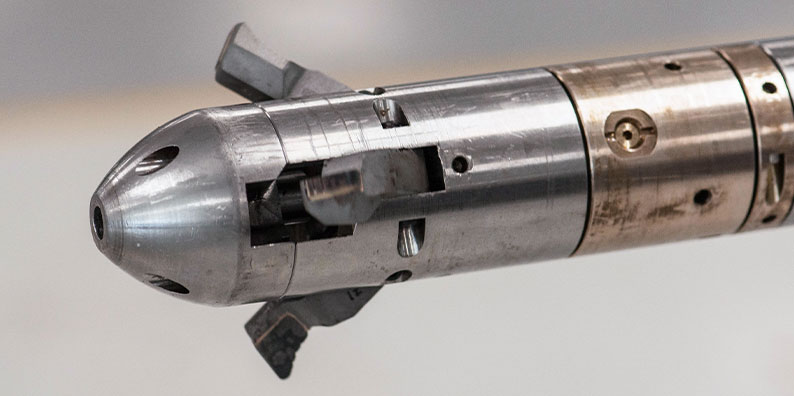

Welltec® was selected as the primary solution for this operation because of its past successes and innovative interventions. The client needed to perform several operations, including a tubing punch to deliver a maximal pumping rate through the punch and a clean cut to enable retrieval. The Welltec® Puncher and a Well Cutter® could be run in combination to optimize the job and make efficient use of rig time. Furthermore, the Well Cutter’s ability to cut in compression would produce a clean cut, making it easier to grapple the lower part of the well/casing.

Operation

The Welltec Puncher and Well Cutter were run in combination, as planned.

The puncher created six uniform holes in a single run, and the cutter provided an efficient and clean cut to the pipe. To reduce operational expenditure, rigless intervention was used for the well.

The expected circulation rate was achieved, and the completion was safely retrieved without overpull.

Achievements

Welltec’s innovative tools and solutions led to several efficiencies for this operation. Performing the operation on e-line enabled the client to opt for a rigless intervention, saving both time and cost. Combining the Welltec Puncher and Well Cutter enabled both the punch and cutting operations to be completed in a single run.

Completing these two operations in a single run ultimately saved 24 hours of operational time for the client. Additionally, running the operation on e-line enabled the client to opt for a rigless intervention, saving both time and cost.

The client’s primary goals were successfully met 24 hours faster than alternative solutions. The expected circulation rate was achieved, and the completion was safely retrieved without overpull.