Well type

Oil producer

Depth

670m / 2,198 ft

Pressure

135 bar / 1,958 psi

Temperature

55°C / 131°F

A long-term, shut-in well in the North Sea had developed into a more pressing issue for its operator.

A third-party setting tool had become stuck downhole without completing the setting sequence approximately five years earlier. Fishing with slickline and jarring attempts had been unsuccessful. A downhole camera investigation later revealed that the lithium batteries had fused, rupturing the battery housing, and the well remained shut in.

In late 2020, the operator observed communication from the tubing to the annulus, and it became apparent that the straddle packer from the incomplete setting operation was leaking. With action needed, Welltec and the operator collaborated to devise an intervention plan.

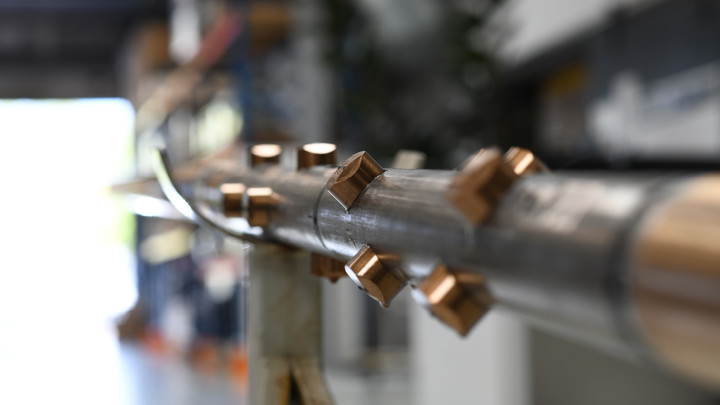

The ideal primary tool for the operation was the Well Stroker® 100k, which was determined to be the best available e-line solution for controlled, downhole stroke force. Crucially, the tool’s hydraulic system can deliver incremental force up to 100,000 lbs. directly to the required location downhole.

Prior to the operation, Welltec conducted a series of tests to replicate the process of retrieving the stuck setting tool, including runs with a Well Miller (RCB) to plan for a scenario in which milling inside the setting tool might be needed to improve the tool’s ability to latch.

The operation included the following tools:

- Well Stroker® 312 (100k) – to apply incremental stroke force up to

100,000 lbs. directly to the straddle.

- Well Miller® 318 (RCB) – to ‘wash-over’ and tackle any debris to the

sides using long-swallow core bit.

- Well Cleaner® 218 Power Suction Tool (PST) – to extract lithium battery

debris.

During the first run, the toolstring unsuccessfully attempted latching. The spear was pulled out of hole and reconfigured with an inclination tool to facilitate a second attempt at deeper latching. For the second run, the Well Stroker was combined with a third-party spear, and the setting tool successfully latched. The Well Stroker then delivered 70,000 lbs. directly to the setting tool, shearing it out from the upper part of the straddle as should have originally happened in the setting operation five years earlier. The Well Stroker and GS pulling tool were run to successfully pull the upper packer on the third run. For the fourth and final run, the Well Stroker and GS pulling tool successfully pulled the lower packer.

Thanks to the Well Stroker’s powerful and directly delivered stroke force, this long-term issue of a downhole fish/shut-in well was finally resolved, and, more importantly, production was once again possible.

The client’s objectives were met as Welltec removed one straddle, facilitating the setting of a new packer to prevent any leakage via the downhole safety valve. From rig up to rig down, Welltec’s operation took only three days. The additional tools for contingencies had been mobilized, providing peace of mind for the client.

The client was extremely satisfied by Welltec’s performance, and the Well Intervention Superintendent stated, “The success of the operation was down to all involved and the excellent teamwork from everyone, both on and offshore, as well as yourselves at Welltec.”