Advanced testing services for CCUS applications at Welltec's Test Flow Loop

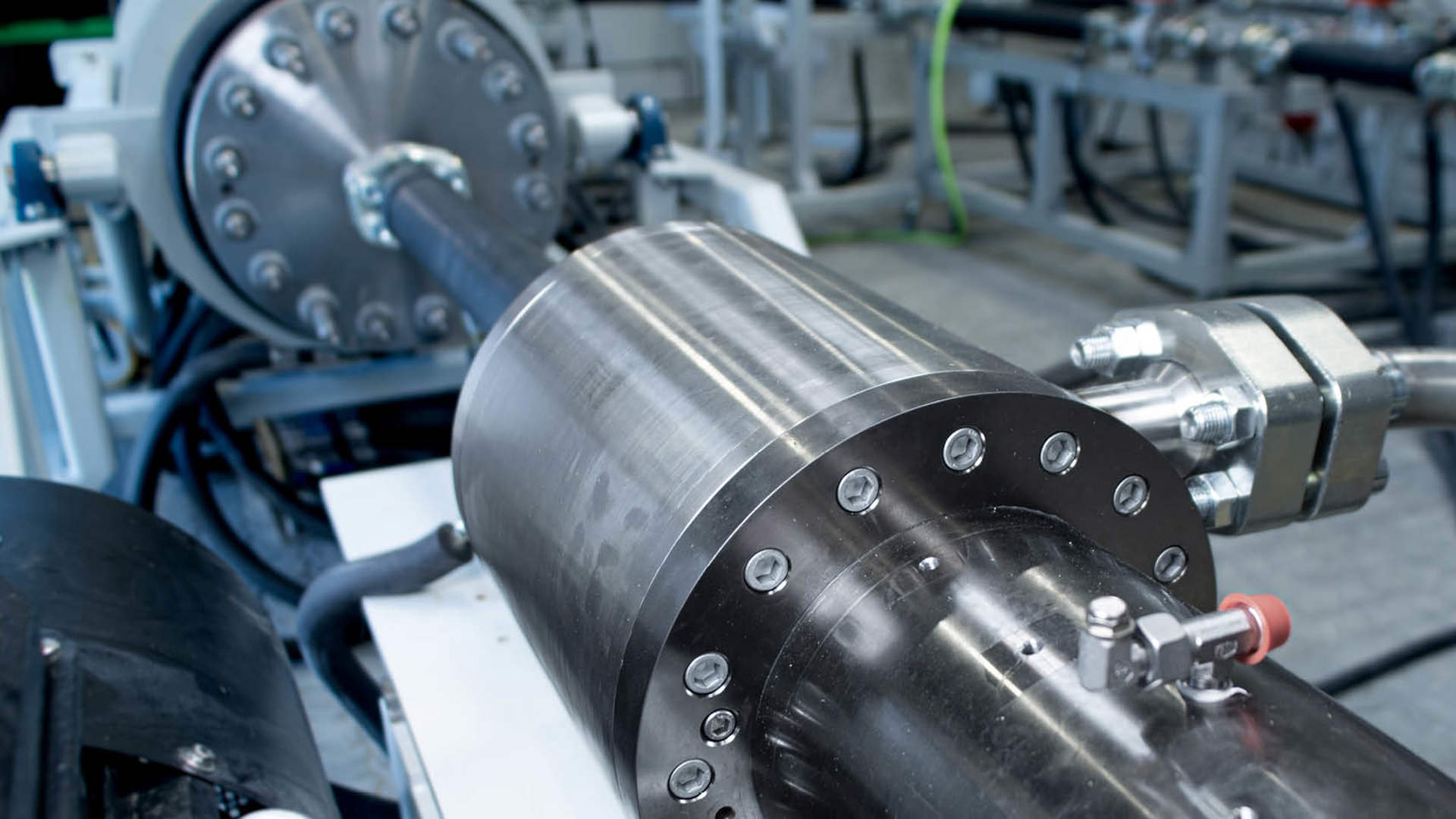

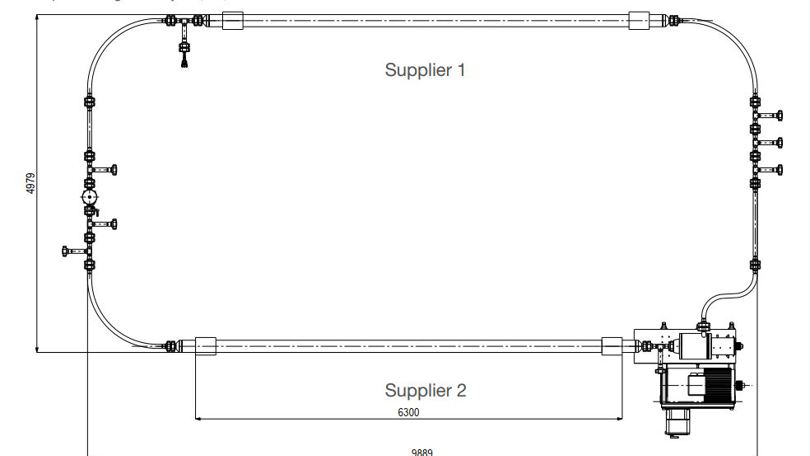

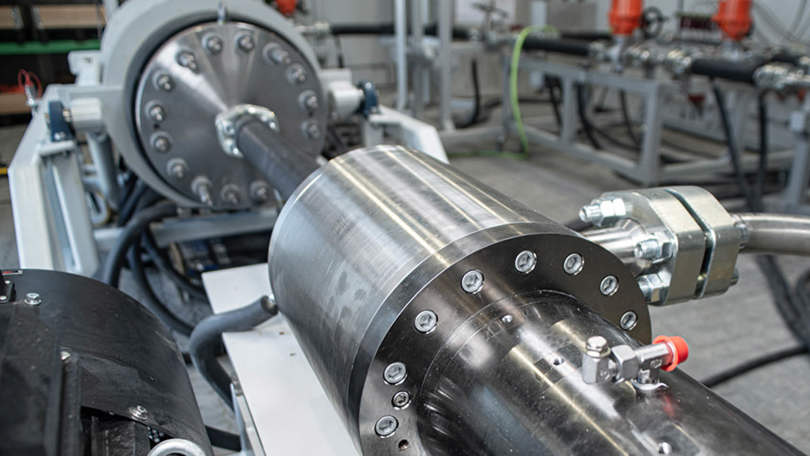

In October, 2022, Welltec established a full-scale Test Flow Loop center in Esbjerg, Denmark capable of re-creating down hole in-situ environments.

The center was design and constructed to allow CCUS operators to test full-scale down hole well components with a high-concentrate CO2 environment, at high pressures and temperature, and with a mixture of chosen impurities.

It was designed with flexibility in mind and can be adapted to a

multitude of different testing applications.

The Test Flow Loop provides the opportunity to:

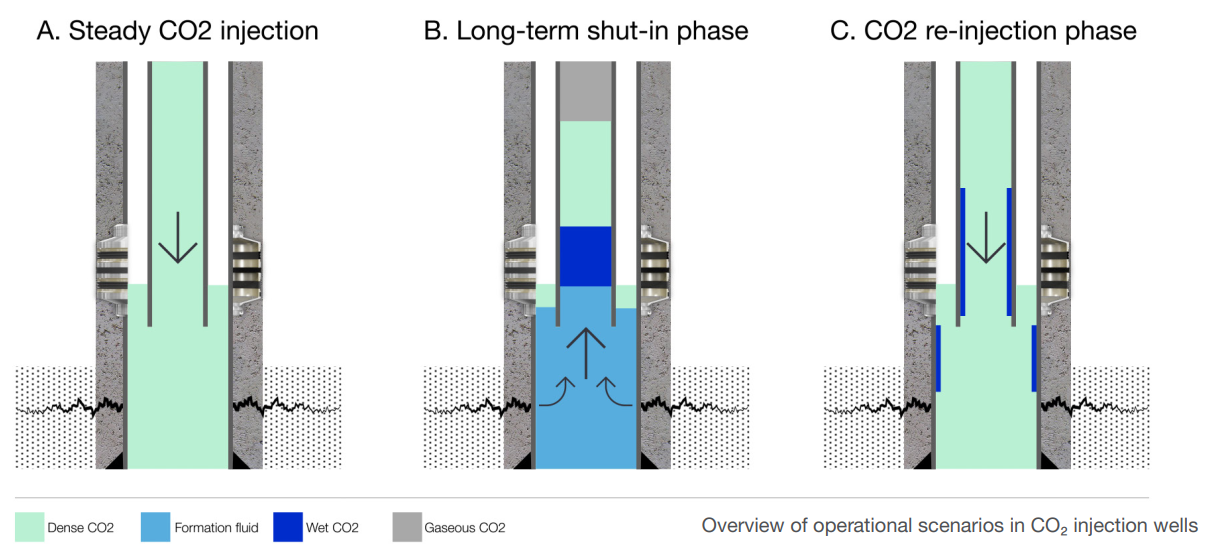

Simulation of the flow back of formation water during long-term

shut-in scenario:

Equipment qualification for CO₂ environment

• Qualification of alternative technologies which contain metallic and elastomeric material which may be affected by CO₂ environment

• The principle of testing equipment is based on exposing it to different states of CO₂ (e.g. liquid, SC or gaseous), depending on the expected scenarios during equipment lifecycle

Further development and deployment plans

• Increase the range of functionality testing, replicating flow through a choke, or valve, with phase change of CO₂ and a higher pressure drop

• Full-size testing of downhole tools/items i.e. complete products

• Structural validation of items after low-temperature exposure or thermal/pressure cycling

• Liquid, dense, or supercritical phase of CO₂ flow through depleted reservoirs, creating phase change of CO₂, hydrates formulation and impact

• Development of test protocols for lifetime qualification of products

• Impurities injection order and control

• Corrosion prediction modelling and Ph measurements in a variety of conditions

• Qualification of Welltec's completion products and intervention tools for operation in a CO₂ environment

Project Greensand

Project Greensand is an ambitious and innovative initiative to develop new ways to capture and store CO2. Welltec® has a long history of engineering and delivering solutions that target complex challenges in the energy sector and now looks to help address and meet the 70 percent reduction of CO2 targets by 2030, as set by Danish government.

With 20+ years of combined experience in oil & gas sector, Lia has been exposed to diversified range of roles, starting from well construction to business development and innovation.

Lia offers strong knowledge within wells, innovation toolkit, business development as well as wide network within emerging market in energy transition area.

Having worked in the upstream sector of oil & gas and geothermal, Joven offers his technical background in well construction and completion to Geothermal and CCUS clients. Joven handles Welltec Green Energy initiatives across APAC and Europe, and collaborates with clients by providing value-added completion solutions focusing on well integrity and risk mitigation.

With 16+ years of experience in the service sector, Yosafat offers a strong technical background for well construction and lower completion solutions to the customer's challenges. Focusing on customer added value.

Minimizing environment impact

We believe in a fair and inclusive energy transition.

That is why we are applying our deep industry knowledge in new energy solutions to prepare for how we can produce more sustainable energy in the future.