Maintaining well integrity and preventing fluid or gas migration

The primary function of an inner-string packer is to create a reliable and high-integrity seal between the base pipe OD and the host casing ID. This seal is vital for maintaining well integrity and preventing fluid or gas migration between different sections of the wellbore.

In addition to the sealing function, inner-string packers might incorporate opposing slips which act as an anchor. The slips are designed to engage with the inner surface of the host casing, providing mechanical support and preventing movement of the base pipe. This anchoring capability is vital in applications where axial or rotational forces may be encountered, such as during well stimulation or production operations.

Welltec® Expandable Anchor (WEA) for Inner-String packer

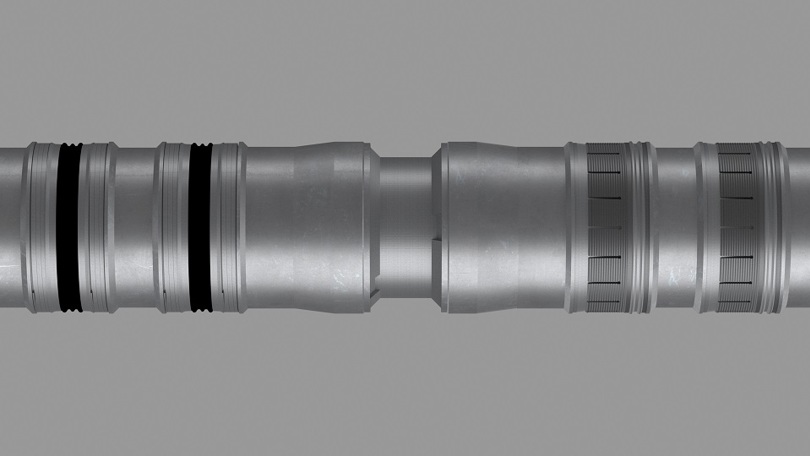

The design of the WEA for Inner-String Packer minimizes subcomponents, ensuring reliability and efficiency while simplifying well construction. The WEA enables reciprocation, circulation, and/or rotation during deployment.

Versatile and compatible technology

The Welltec Expandable Anchor (WEA) for Inner-String Packer is run in combination with a Metal Expandable Packer (MEP), i.e., a proven hydraulic expansion sleeve.

The rapid application of surface-controlled pressure simultaneously expands the WEA and the MEP system, offering an efficient alternative to conventional inner-string solutions. The expansion sleeve hydraulically expands the bidirectional anchors, which uniformly engage with the ID of the outer casing. Increased loading/anchoring capacity is achieved via the modular addition of WEA sleeves.

The system is compatible with many casing internal diameters and feedthrough lines. Its slim running OD provides a solution in scenarios where casing ID restrictions prevent deployment of conventional packers – the WEA solution also eliminates the requirement for a de-burr run when deployed within the perforated tubing.

With over 11 years of experience in well completion, Tolegen works on well construction improvement and well completion optimization in the dynamic CIS region. He supports our customers to analyse technical challenges and select the most suitable technology.

With 16+ years of experience in the service sector, Yosafat offers a strong technical background for well construction and lower completion solutions to the customer's challenges. Focusing on customer added value.

Peter has a proven international track record in delivering commercial success and developing key customer relationships. He has experience in various Completion roles over a 22-year period, progressing through Field Operations, Account Management, and Business Development. Projects include downhole monitoring, artificial lift, and subsea installations.

Maximizing reservoir contact

We help maximize reservoir contact to optimize productivity and maintain maximum well delivery. Our unique completion technologies provide a new perspective to drilling and completing wells, adopting a holistic approach which adds value continuously over the life cycle of a well.