Ultra-slim relining and repair solution

With no more than a 4-10 mm effect on the inner diameter (ID), this patch-thru-patch solution offers all the benefits of straddles and larger steel patches, but with a more rapid deployment capability and total flexibility for customized relining, repair, and well integrity.

Featured case

A groundbreaking intervention in a European onshore gas producer, where a shallow leak had developed in the 3-½” (9.3 ppf) tubing, just below the Tubing-Retrievable Surface Valve (TRSV), resulting in tubing to A-annulus communication.

Featured case 2

In Alaska, the Isealate Springblade Patch remedied a critical tubing connection leak at 5,000 ft while preserving ID within strict limits. A pressure test at 172 bar held for 30 minutes with zero loss, and post-op caliper log confirmed just a 7 mm reduction in diameter. The operation restored well integrity under challenging conditions, enabling production to return to optimal levels.

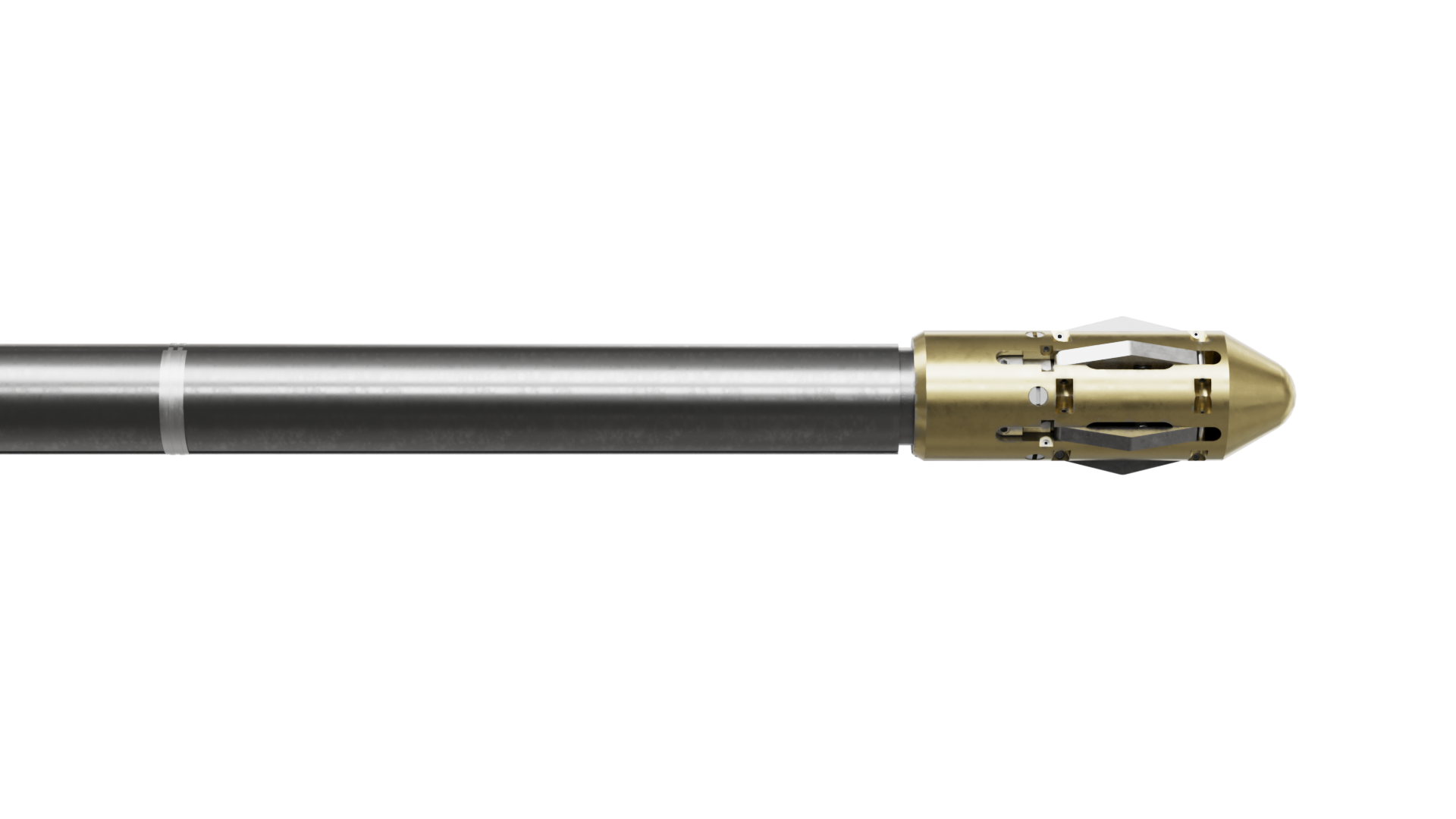

Each Isealate Springblade Patch is deployed in a pre-rolled form, held under tension by shearable clamps.

When run in hole, the patch is delivered to the precise location required to cover the leaking or damaged section of tubing, and is quickly expanded by a setting tool controlled at the surface.

The patch immediately conforms to the tubing ID, and a heat-activated resin (pre-applied) further facilities complete sealing.

The slim design allows for subsequent patch-thru-patch deployments and does not interfere in any way with future interventions.

| Applications |

| Leaking connections and tubing holes |

| Screens |

| Slotted liner |

| Seal off Inflow Control Valves (ICV) |

| Lock-Open TRSV Flapper |

| Features |

| Installed by the purpose built Isealate Patch Activation Tool |

| Can be punched/perforated after being installed |

| Patch Material: EN 1.4310 2H / AISI 301 2H |

| The epoxy cures and hardens by well temperature |

| V3 qualified |

| Benefits |

| Not limited by well restrictions |

| Patch-thru-patch application |

| Minimal loss of internal diameter |

| Deployed on standard e-line (monoconductor) |

| Specifications* | |

| Patch Activation Tool OD | 2.68” - 3.55” – 4.33” |

| Tubing Range | 3 ½” – 6 5/8” |

| Patch length | 3.3 ft – 14.8 ft |

| One layer thickness | 1/64” |

| Well temperature range (Springblade Patch) | 104 – 250 F* |

| *Temperature range will depend on application type and transport requirements, contact Isealate for specific operational needs |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.