High temperature all metal expandable packer for Geothermal Applications

Geothermal energy offers the highest capacity factor in the renewable market and requires a consistently high temperature fluid flow to ensure a reliable output. Welltec® offers multiple solutions using an all metal expandable packer to assist operators in various stages of drilling and completion.

Welltec® Magma Packer can be incorporated into existing casing program helping achieve challenging high temperature cement jobs during new well construction, enable the sustainable rejuvenation of existing shut in wells via re-lining and provide open hole isolation for Enhanced Geothermal Systems (EGS) and stimulations.

Current designs of the WMP are qualified for 260 > 300°C, which can be used for injection and production wells with the possibility of modifications to address specific requirements.

Featured case

A Welltec metal expandable packer (MEP) was adapted for high-temperature service to re-line a shut-in geothermal producer after casing and liner failure from acid corrosion. Set inside 9-5/8” casing, the MEP supported cement curing and prevented contamination, restoring the well at a fraction of the $9M cost of drilling a new well. The success secured further geothermal deployments.

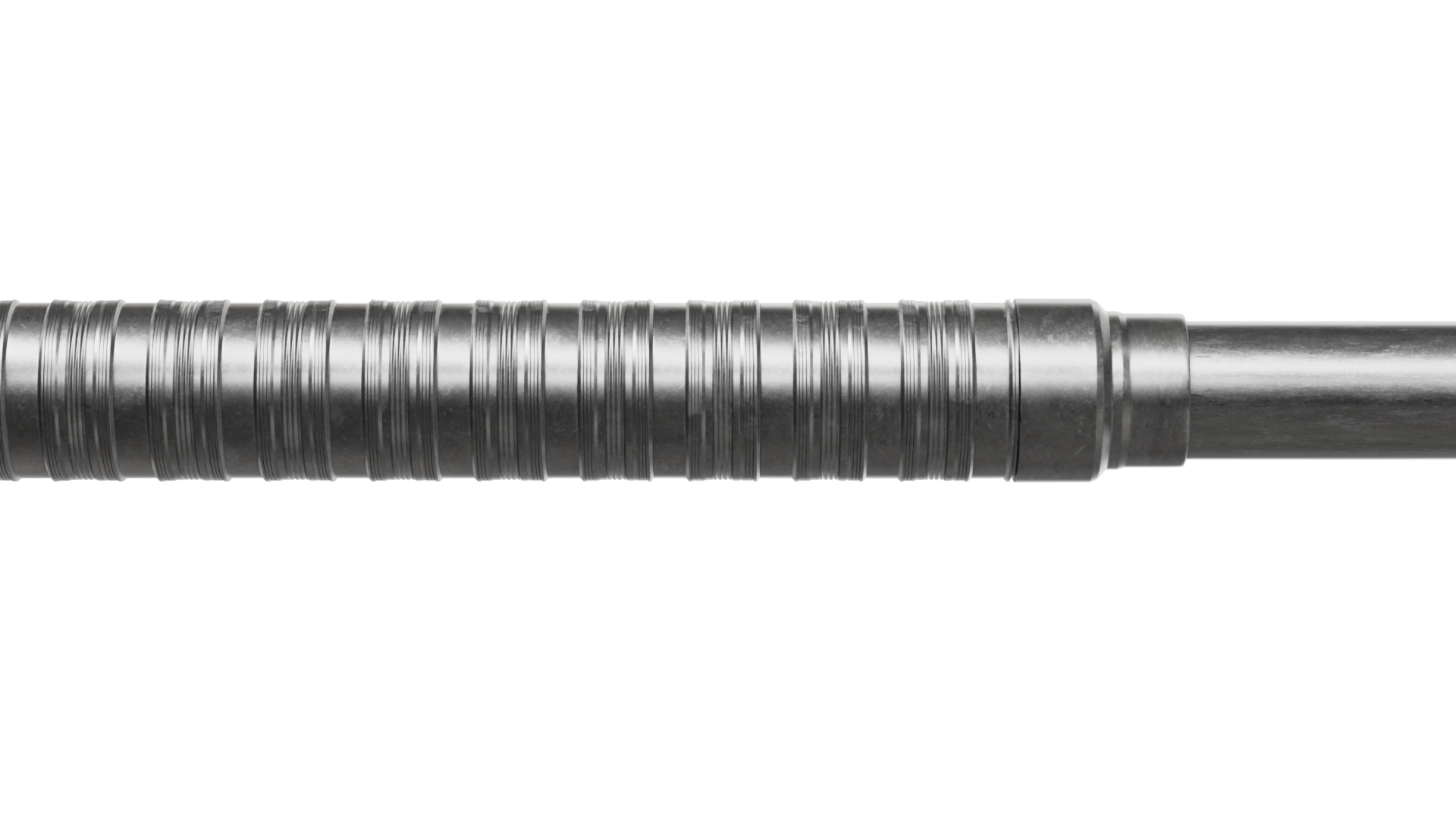

Our ISO 14310 rated, all metal expandable WMP (Welltec Magma Packer) is expanded between the base pipe and the casing or the borehole by applying pressure in the casing. It conforms to the actual well bore geometry or casing internal diameter, providing metal to metal or metal to rock contact, and high strength anchoring capability.

Once the WMP is set, casing Integrity is re-instated via internal hydraulic isolation mechanism.

The packer can be mounted and welded onto any base casing in a simple and cost-effective way. Both ends are therefore fixed and provide life of well protection to the expanded sleeve.

| Applications - well construction: |

| Open hole & cased hole 2nd stage cement support |

| Standalone open hole isolation |

| Open hole & cased hole cement assurance |

| Platform for 2nd stage cement during relining shut in wells |

| Cross flow isolation |

| Liner / casing hanger |

| Applications - zonal isolation: |

| Enhanced Geothermal Systems |

| Cold water isolation |

| High pressure oh isolation for stimulation |

| Replace cement |

| Suitable for all formation types and borehole geometries |

| Features |

| Rugged, all welded, metallic construction |

| Optional isolation of expansion port |

| Expansion assurance in multi-WAB applications |

| High temperature capability |

| High expansion capability |

| Constant, high pressure ∆p over full expansion range |

| No premature expansion |

| NACE compliant |

| Control line feedthrough optional – to communicate with hyd. activated devices |

| Benefits |

| Rotatable during deployment enabling liner to TD in challenging environments |

| Deployable through milled / damaged casing |

| Slim OD allows for high rate circulation during deployment |

| Rapid set nature of WAB reduces time to production |

| High rate circulation capability |

| Full bore – as per casing / tubing |

| Specifications | |

| Expansion range | 6.25” → 13.50” |

| Min. running OD | 5.900” → 11.380” |

| Max. working pressure | 5,000 psi → 10,000 psi |

| Constant element ΔP across expansion range | 5,000 psi → 10,000 psi |

| Standard element length | Up to 6.4 ft *** packer length can be customized |

| Temperature range | 500 ̊ F → 572 ̊ F |

| Base-pipe range | 4 1/2” → 9 7/8” |

| ID | Full bore (as per base-pipe) |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.