Well type

High MW geothermal producer

Reservoir type

Basement

Product placement

9 5/8" casing

$8MM Capex savings

Realized via enhanced work-over vs new drill well

High temperature & pressure WAB

Enabled enhanced CAPEX-effective well construction

Welltec breakthrough success

In renewables market segment with high-temp WAB

Location

Philippines

A geothermal well operator had to shut in one of its most prolific producers due to the failure of the 9 5/8” casing and the loss of the 7” slotted production liner – the result of acid corrosion.

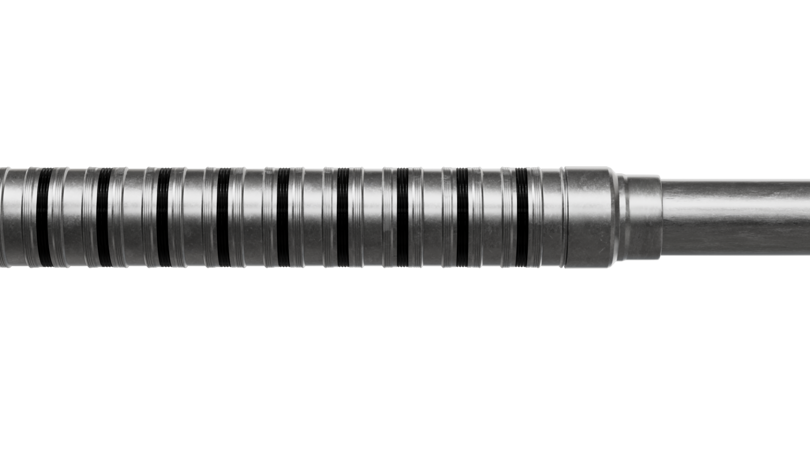

Welltec® offered a 812 Welltec Annular Barrier (WAB®) as a solution to provide a foundation for pressure support to the column of cement slurry placed above, preventing the curing cement from becoming contaminated.

An 812WAB would also offer anchoring support to the casing string in the event of thermal contraction or expansion during production or shut-down operations.

A standard 812WAB was adapted to incorporate non-elastomeric isolation valves and burst discs to facilitate bleed-off in the event of high-pressure steam build-up behind the casing. The 812WAB was run just above the high CRA 7” casing tailpipe and set inside the existing 9 5/8” casing. Second stage cementing was performed above the installed 812WAB.

During deployment, water flooded the well to keep temperatures ≤ 212°F – full production temperatures would be 545°F. The adapted 812WAB supported the cement column during curing and prevented free-water/acid from contaminating the cement or reaching the surface.

This operation represents the second time that a WAB has been used to revive a geothermal well, and a continuation of Welltec collaborating with the geothermal sector in the Philippines. The client has since provided estimates that a new well would have cost upwards of $9mm.

Welltec facilitated a life-of-well, CAPEX-effective well-rejuvenation methodology, proving the value of engineered well remediation techniques.

This initial success has led to the client purchasing an additional 1214 and 812WAB for the deployment on upcoming wells to address the same issue.

WAB® for Well Construction & Integrity (Welltec® Annular Barrier)

CAPEX effective, enhanced well integrity via metal expandable packers