Well type

Oil producer

Bottomhole temperature

180° @ 12,000 ft

Max. depth

23,512 ft

Total distance tractored

11,583 ft (3,530m)

In June 2018, a west-Texas operator needed to identify a restriction in production casing at approx. 18,200 ft. The restriction had blocked a plug and perforating gun combo in an extreme 23,600 ft lateral on a multistage frac operation.

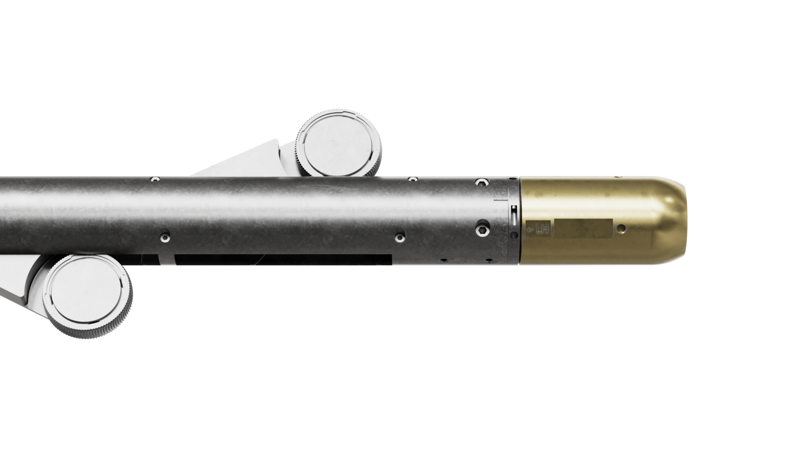

The operator opted for a downhole video camera and a multi-finger caliper tool paired with the Well Tractor to identify the restriction. Conveying the camera and calipers would provide surface personnel a live video feed so they could make decisions based on both caliper data and visual of the ID of the well.

Fresh water was pumped into the 5.5” x 4.5” casing so the camera could provide quality video downhole. The Well Tractor conveyed the camera and caliper tool through the lateral, over 10,000 ft, to TD at 23,512 ft. Caliper data indicated four casing collars had minimum IDs smaller than the 3.795” drift ID with average IDs of ~3.71”.

At each of these anomalies, live video showed ovalization ~1–2 ft above each collar.

The run identified one other anomalous casing collar located at 14,686 ft but video showed only debris, no ovalization.

This is the first operation in which a camera was run in combination with a caliper tool on the Well Tractor in a single run. The Well Tractor conveyed the camera and caliper tool throughout the lateral, tractoring over 10,000 ft.

The live data and video from the caliper tool and camera helped personnel identify the anomalous readings as over-torqued collars with some buckling above the collars. E-line tractor interventions can succeed in place of heavier methods, like CT, and provide operators with additional, useful tools integrated into a single run in hard-to-reach laterals.