Well type

shallow geothermal

Max. deviation

89.66°

Target depth

1420m TD / 4,659 ft.

Max. pressure

65 Bar

Max. temperature

50°C

Just like any other, a geothermal well can require logging to determine the volume and condition of the wellbore.

Welltec’s client based in the Netherlands wanted to carry out a caliper survey on a recently drilled shallow geothermal well, which once completed would supply heat for greenhouse agriculture.

Going into the operation, it was suspected that sand ingress had occurred due to perforated liner damage.

With the client considering various means of carrying out the logging operation – including Coiled Tubing (CT) and their own camera technology – they opted for a collaborative solution, whereby Welltec would provide best-in-class conveyance via Well Tractor technology.

With the operation taking place just 1km from an urban settlement, local noise restrictions meant a heightened emphasis on fast and efficient turnaround, facilitated by Welltec’s lightweight tools.

Tools and equipment were promptly mobilized from the UK, and the requirement of a single field engineer was quickly arranged within the Netherlands after the completion of another job.

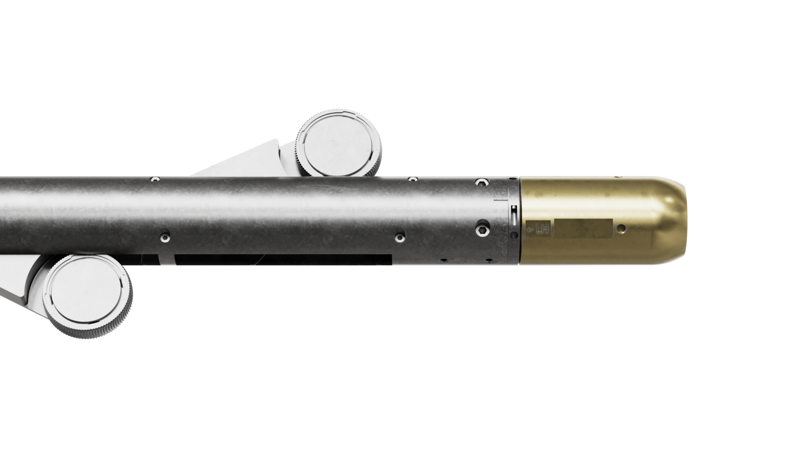

A tandem 412 Well Tractor® was deployed with third party logging equipment. Over two runs a multifinger caliper was conveyed in 7 5/8” 26.4# liner, from 2,615 ft. to 4,659 ft. (MIT60), and then larger MIT80 for logging 13 3/8” 68# Casing from surface down to 2,690 ft.

The two runs were carried out within 12 hours, with no service quality issues.

The primary goal of logging conveyance was achieved and revealed a parted liner. The drilling rig was subsequently brought back to site by the operator, with drill pipe redeployed and a patch set to repair the damage.

Thanks to the collaborative approach taken in this operation, Welltec was able to provide conveyance to deliver a higher quality of data collection in comparison to the client’s alternative options.

Welltec’s rapid deployment capability facilitated two logging runs and helped gather a clarification of the issue within 12 hours, including rig-up and rig-down. An alternative CT-based operation could have been expected to take 48 hours to complete.

Minimal environmental impact was achieved across the board in this operation, as lightweight and efficient tools and a solo crew facilitated the completion of a geothermal well to provide heat to greenhouse agriculture.

Indeed, these factors also facilitated the fast turnaround of daylight only operations, being just 1km from a nearby town, and complying with local noise restrictions for urban areas.