Milling of slickline fish to restore production

- Well type Oil producer

- Bottom hole pressure 11,500 psi

- Bottom hole temperature 210 °F / 99 °C

Background

An operator from the Gulf of Mexico shelf had issues with retrieving a Side-Wall Cutter (SWC) after it became stuck at 10,700 ft.

The objective was to clear the (slickline) debris and access the fishing neck of the SWC. Prior to Welltec’s involvement, the operator had deployed multiple slickline fishing tools in attempts to retrieve the SWC with no success, the upshot of which was a six-month shut-in of the well.

One option to resolve the issue involved a cleaning and milling operation that would be completely delivered via Coiled Tubing (CT). However, this method carried an initial high risk of causing damage to the fishing neck of the SWC, which could permanently shut the well in.

With Welltec now involved, a safer alternative plan was developed to recover the top/primary fish, before going with CT into 2-3/8” tubing to clean out the well and get it back online.

Operation

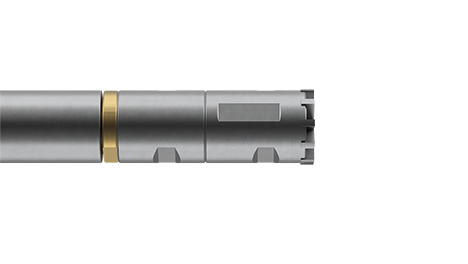

Welltec’s strategy was to carefully utilize a 218 Well Miller® to mill the stuck slickline and prongs by way of a modified coring bit to mitigate any risk of damaging the SWC fishing neck. A stopper was also placed inside the 2” OD milling bit in order to provide a ‘no-go’ function before getting to the fishing neck.

To begin with, it needed to be established that the 2.125” toolstring could pass through the 2.188” ID restriction without issue, and this was proven by way of a crane test.

Working alongside a third-party wireline company in a first-time collaboration, joint meetings were carried out to address and action any items required to move forward with System Integration Testing (SIT) and mobilization.

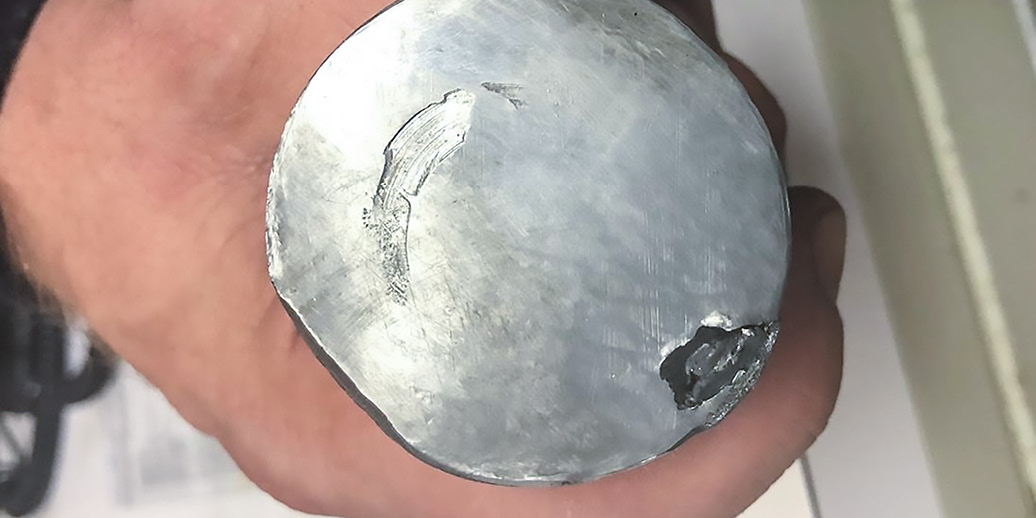

With testing successfully completed, the 218 Well Miller was deployed. After each milling run, slickline was deployed with magnets to pick up loose slickline debris.

In the event that a more intensive cleaning run was required to collect debris, a 218 Well Cleaner® Power Suction Tool (PST) had also been mobilized and was standing by.

Achievements

This operation represents the first ever milling of stuck slickline in the Gulf of Mexico shelf using a line-deployed milling solution. The SWC was successfully retrieved and the operator was able to avoid the permanent and undesired shut-in of the well.

It was after the fourth milling run when slickline was successfully latched onto the fishing neck of the SWC to pull it out of hole.

Retrieval of the SWC (as the first/top fish and therefore primary obstacle) enabled the client to subsequently deploy CT into 2-3/8” tubing to clean out the well and get back online, with deferred production of ~5.5M USD.