Closing of a FS2 valve on wireline

- Tubing size 7"

- Max. deviation 87° (82° @ FS2 depth)

- Max. depth 2.240m MD

- Max. DH pressure 2.250 psi

- Max. temperature 210°F

- Distance tractored 146m

Background

An offshore operator in Malaysia had just completed a large bore gas production well, when they detected a build-up in the annular pressure. A leak detection tool was run with the Well Tractor® 318 XR and leaks were found at the tubing connections at 333m and 394m-MD. A decision was made to re-complete the well. In order to save time killing the well and removing the tubing, the client chose to close the FS2 fluid loss isolation valve at 1.800m-MD.

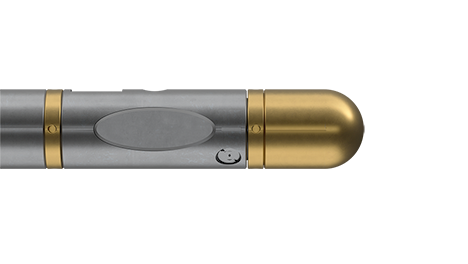

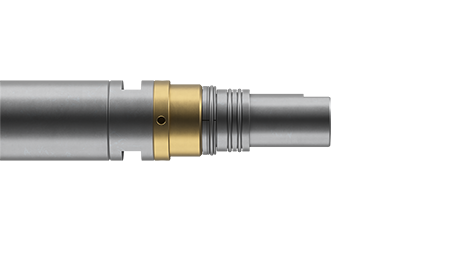

The Welltec® suite of Well Tractor and mechanical intervention services were already chosen as a contingency operation for opening the FS2 valve. Due to its ability to close the FS2 valve a well, a package consisting of the Welltec Release Device®, Well Tractor 318XR, Well Stroker® 318 XS and Well Key® 318 was selected for the re-completion.

Operation

To close the FS2, the aforementioned toolstring was configured with a 4,625” FS2 key pad and run in the hole. The Well Tractor was activated 146m above the FS2 Valve and then tractored down to the FS2 valve where a depth correlation was made. Then the toolstring was tractored into place with the key extended until it reached the recess area above the shifting profile.

The Well Stroker piston was extended with the key pads expanded and located the shifting profile. Next the Well Stroker was activated to stroke up and thereby closed the FS2 ball valve. The successful operation was confirmed by performing a one hour inflow test at the FS2 ball valve.

Achievements

The client achieved:

• Time saved by doing this intervention with a ‘light’ touch using tractor/e-line compared to the use of a drill pipe conveyed running tool.

• Time/cost saved from not having to kill and then unload the well

• In addition to re-completion cost and rig time saving, the client avoided reservoir damage from fluid invasion by not having to kill this well to re-run the upper completion.

• This well was naturally unloaded underlying the benefit of having avoided such fluid invasion and a well killing operation.

• Not only was the operation a success, but Welltec also managed the first time achievement of closing a Halliburton FS2 Fluid-loss Valve using tractor conveyed tools on wireline after successfully cycling open the valve.

In addition to re-completion cost and rig time saving, the client avoided reservoir damage from fluid invasion by not having to kill this well to re-run the upper completion.