Cement assurance between differentially depleted layers enabling high-pressure multi-zone frac

- Well type Well 1 Producer / Well 2 Injector

- True Vertical Depth (TVD) 29,000 ft / 8,839 m

- Qualified to ISO14310 V3

- Location Gulf of Mexico

- Achievement Cost savings of $3.5M USD per well

Background

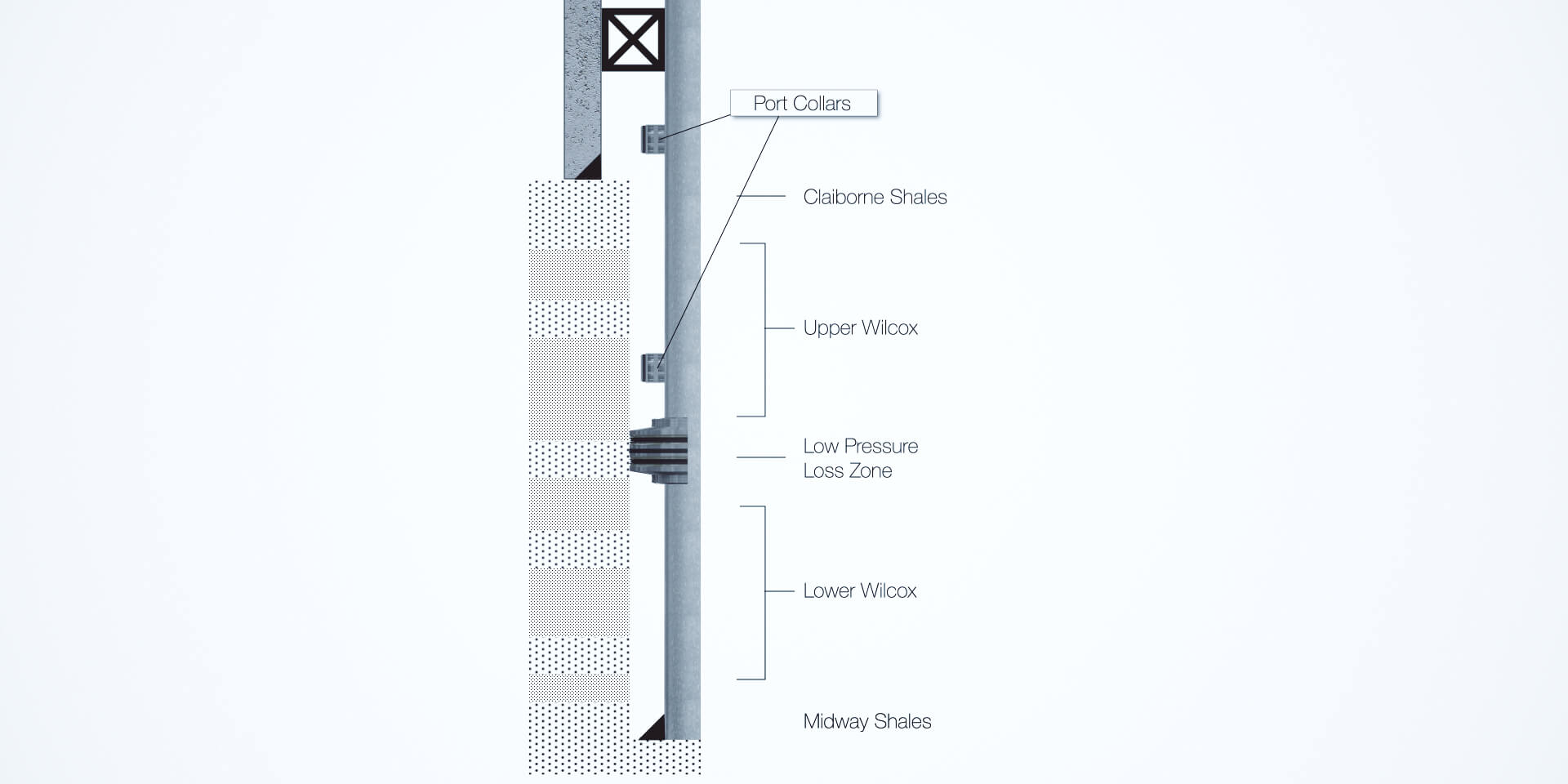

The prolific Wilcox Formation in the deepwater field Gulf of Mexico has been producing since 2014 and faces high depletion pressures of up to 8,000 psi. Isolation of the depleted zones is therefore essential for a proper cement placement in the context of well completions.

A large IOC faced the challenge of achieving effective zonal isolation between differentially depleted layers of the reservoir which is a necessity to meet regulations and to maximize production through an effective zonal frac. A low-pressure zone within the reservoir increased the risk of cement losses, which in turn would lead to the loss of zonal isolation.

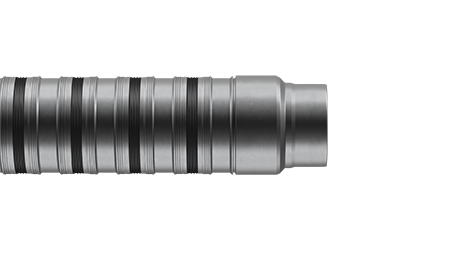

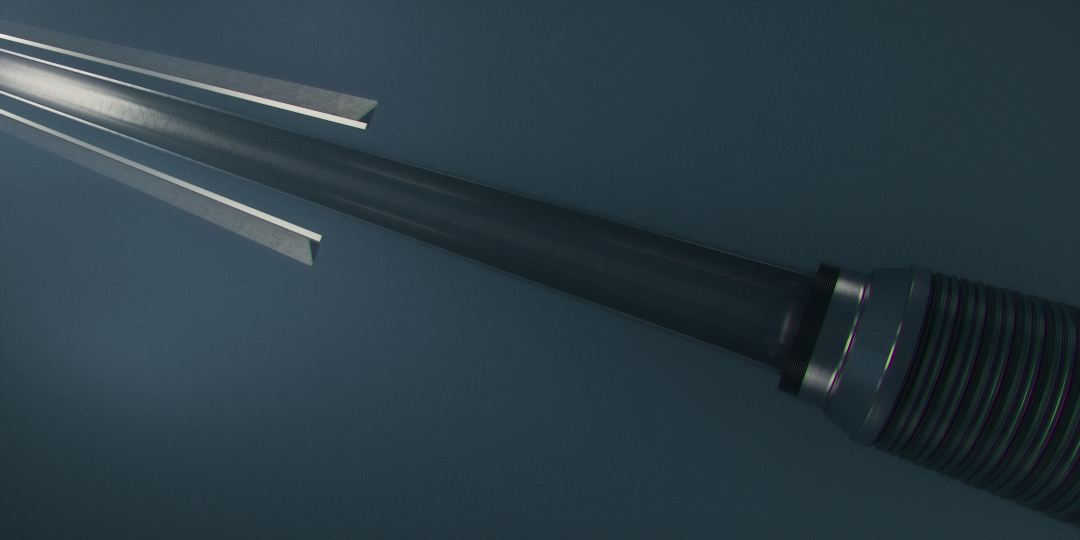

Complex remedial cement jobs were held as contingency with associated high cost and operational risk. With Welltec® providing three of 1214 Welltec Annular Barrier (WAB®) for two separate wells (one in the first well and two in the second), individual formations were isolated at ~30,000 ft.

The operation represents Welltec’s first two lower liner zonal isolation completion deployments in the challenging deepwater Gulf of Mexico, and for this particular client.

Operations

Well – 1:

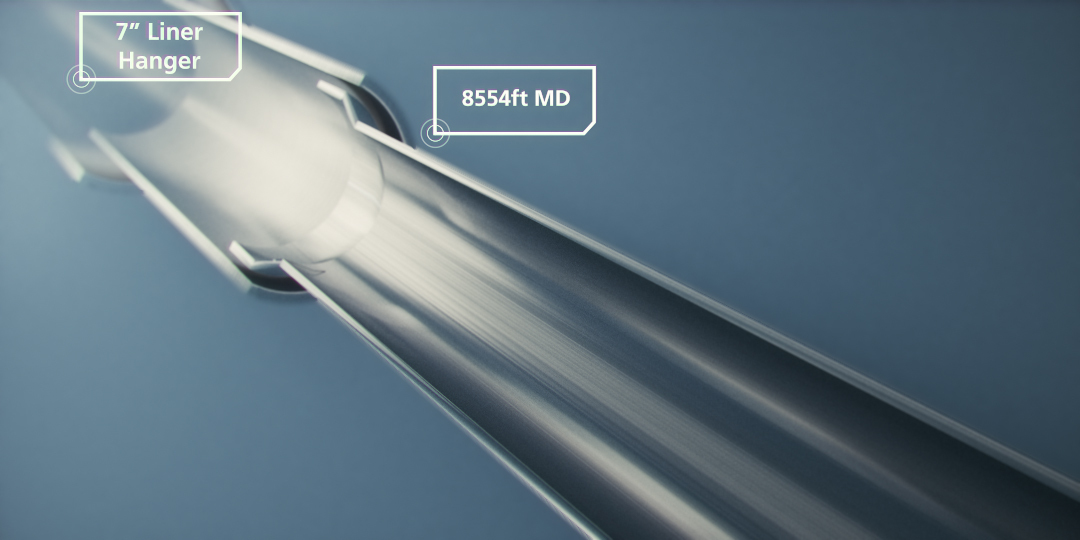

The 10-1/8” liner was deployed with a 1214 WAB premounted on the same size casing.

Once the liner hanger reached target depth, full circulation was established. With returns decreasing, the volume correlation suggested that the pack-off (bushing) was at the liner hanger.

With the well on losses, pump pressure was increased to break the pack-off and retrieve it.

The liner hanger was set, final WAB expansion would occur due to fall off in annulus pressure or during subsequent HP Frac.

Well – 2:

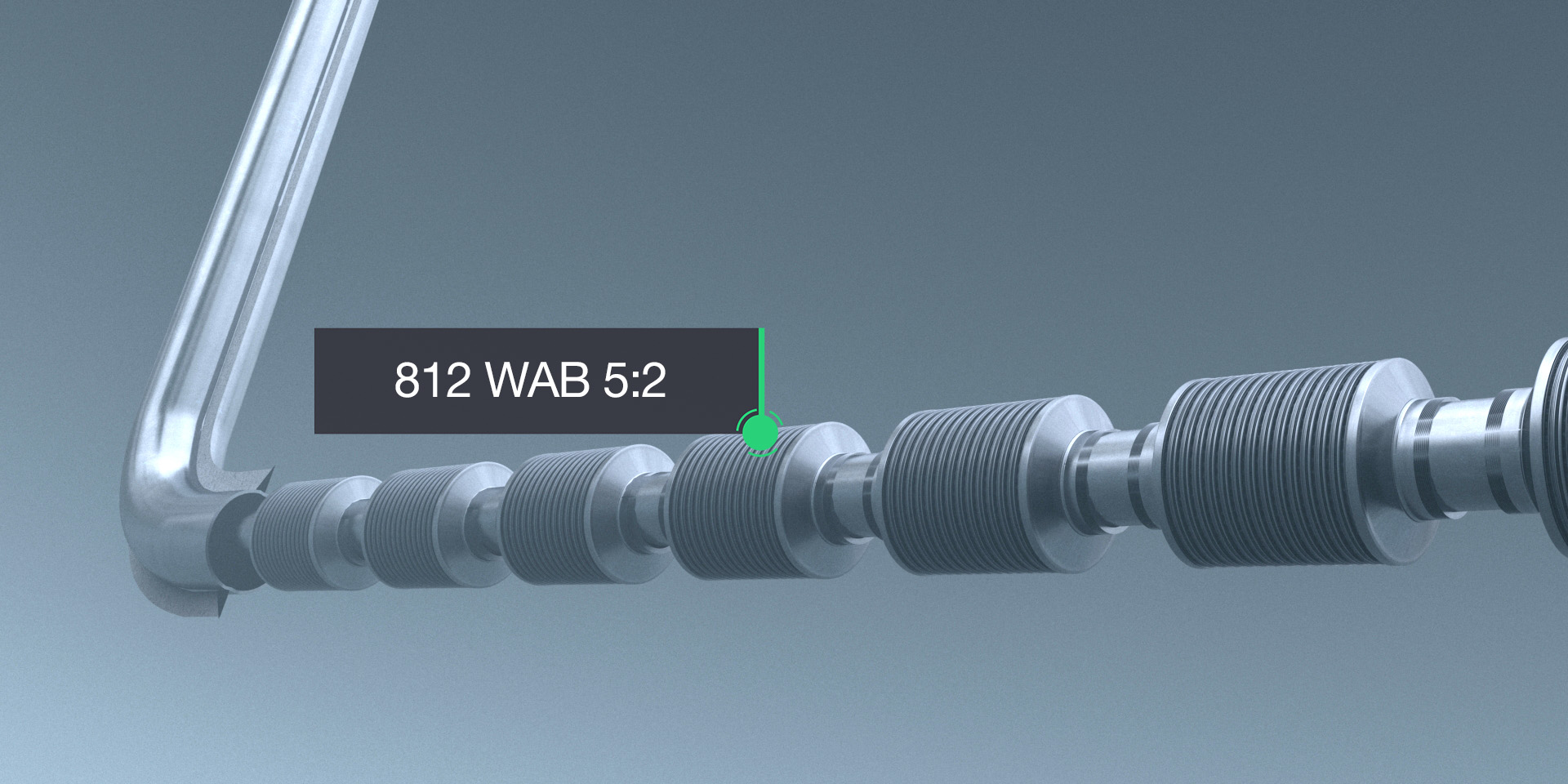

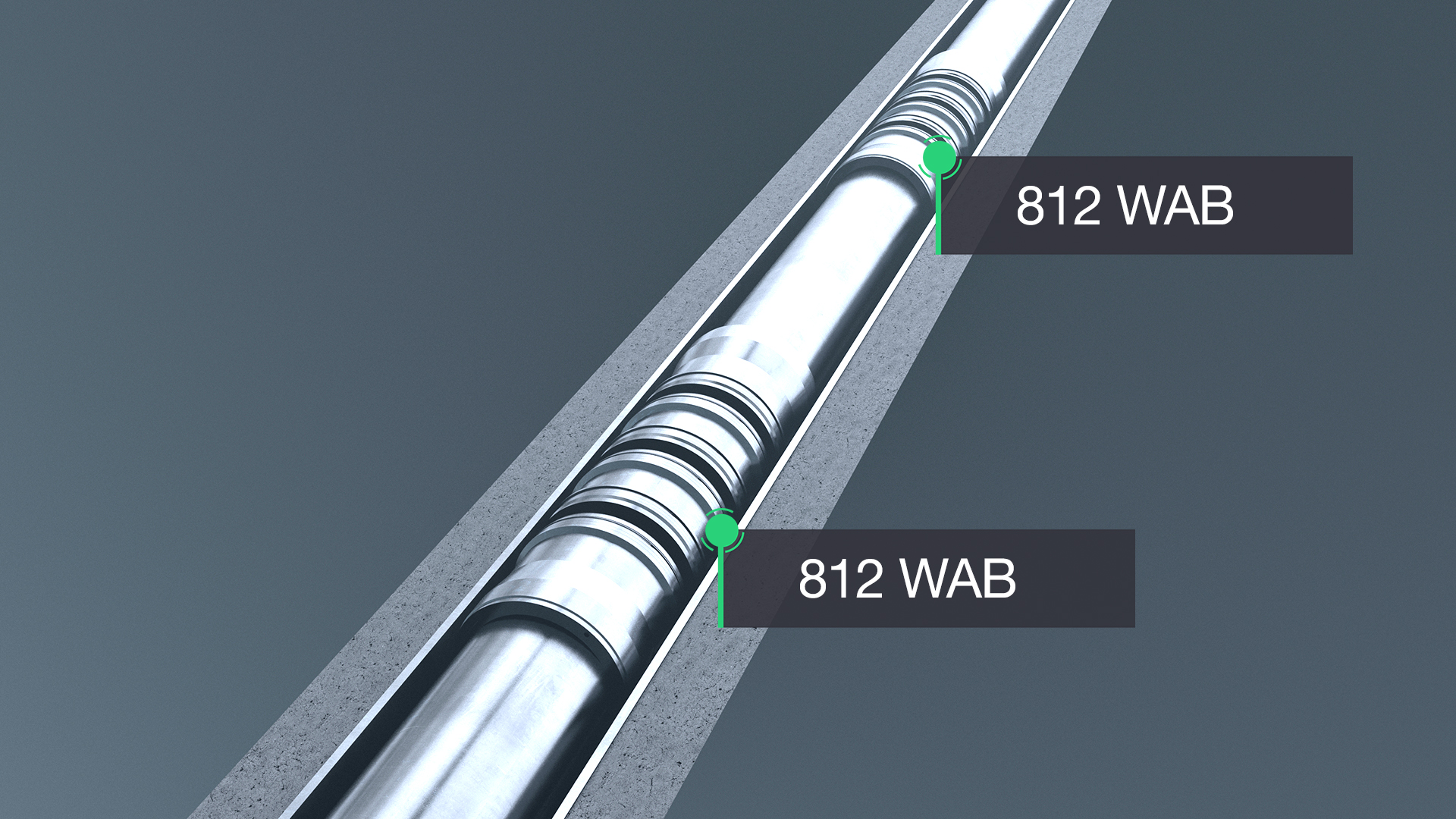

Two WABs were deployed (premounted) on the 10-1/8” liner within the hole down to 29,000 ft. true vertical depth.

With primary cementing operations completed and the cement plug landed, the WABs were successfully expanded via 6,300 psi surface pressure (5,400 psi liner differential pressure).

The WABs were expanded quickly in the wet cement and under full surface control.

Achievements

By utilizing a total of four 1214 WABs, reliable cement assurance was provided in two separate completions, achieving zonal isolation during a high-pressure frac.

The successful deployment in deepwater high-pressure wells removed the need for high risk and high cost alternatives and contingencies, resulting in an estimated cost saving of $3.5M USD per well.

WAB technology delivered all of the operational objectives with life-of-well zonal isolation and qualification to ISO14310 V3.

Well schematics