for Hardware Milling

The Well Miller for Hardware Milling optimizes the repair of wells with mechanical problems by milling out the faulty hardware with keyhole precision. Hardware milling is performed in combination with our Well Stroker® HM to apply weight-on-bit as necessary and counter the reactive torque.

The Well Miller for Nipple Profile Removal (NPR) is developed to increase the ID of a nipple profile, the Well Miller NPR provides increased production and access to the wellbore below for tools with larger diameters. We have also successfully applied the Well Miller NPR to open up pipe or tubulars which have partially collapsed. Our track record speaks of successfully removing nipples of high tensile steel, chrome, and super chrome.

The Well Miller for Plug Removal (PR)

A powerful solution for removing faulty or temporary plugs in the wellbore. Even the hardest materials such as cast iron or composite plugs can easily be milled out with the Well Miller PR.

The Well Miller Valve Opening (VO) If valves malfunction the Well Miller VO can help restore production to the well by milling out a predetermined part of the valve. When a control line fails or a valve doesn’t open, it affects both production and wellbore access below the valve. A swift solution is therefore always desired. The Well Miller VO is able to quickly and safely restore the flow path.

The Well Miller Valve Removal (VR)

Flapper valves, half and full-ball valves and isolation valves pose no obstacle for the Well Miller VR. Valves made of high tensile steel, chrome, super chrome, incoloy and inconel are easily removed to establish or even increase production.

The Well Miller Ball Seat Removal (BSR)

The tool has been designed especially for milling out balls and ball seats to increase flow and allow access to lower completions. Through the years we have successfully milled out balls and ball seats made of cast iron and composite materials.

Featured case

A highly deviated subsea production well in the North Sea was experiencing problems with a deep-set bridge plug. The well was drilled and completed in 1999 and...

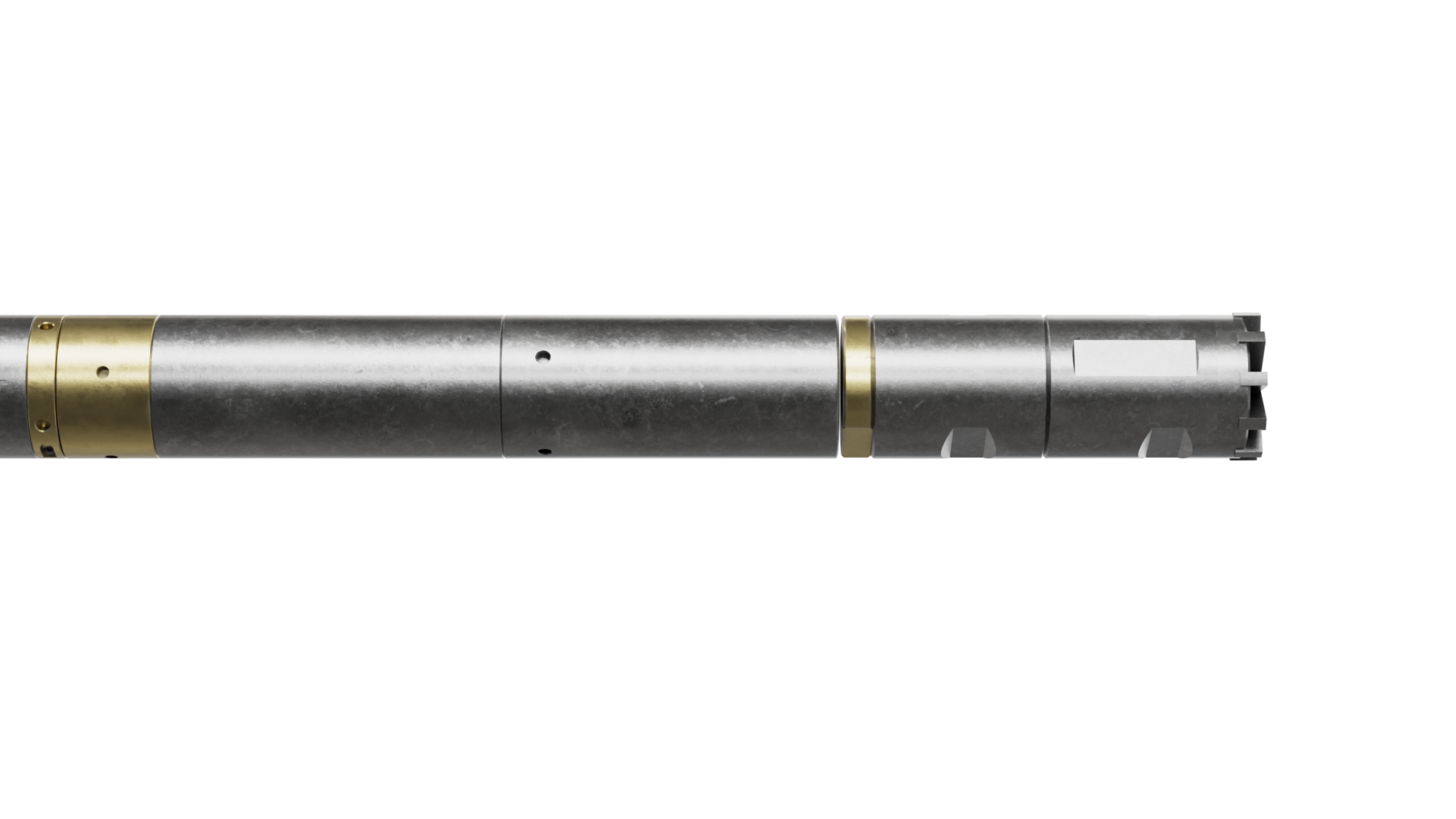

The Well Miller provides operators with a better way to repair wells with mechanical problems.

Using only e-line tools, nipple profiles or other restrictions can be eliminated or increased, plugs can be removed, failed isolation valves can be milled through for production or access to deeper parts of the wellbore. The Well Miller is run in combination with the Well Stroker HM for precise control of weight on bit and to counter reactive torque.

| Applications |

| Nipple profile milling |

| Access through failed isolation valves |

| Cement plug milling |

| Enlargement of buckled tubing |

| Glass plug and bridge plug removal |

| Ball valve / seat milling |

| Isolation valve milling |

| Features |

| Passive fail-safe system |

| Modular |

| Surface read-out |

| Variable heads based on objective |

| Wide range of sizes |

| Universal |

| NACE compliant |

| Benefits |

| No additional fluids required |

| Provides access to TD |

| Large range of ID’s accessible |

| Recovers the debris from the well |

| Accurate depth control |

| Operates on any e-line via DC |

| Specification range* | |

| Tool OD | 2 1/8” → 3 1/2” |

| Length | 10 ft → 12,2 ft |

| Weight in air | 70 lbs → 95 lbs |

| Min. completion ID | 2.25” → 3.6" |

| Max. well pressure | 20,000 psi → 25,000 psi |

| Max. well temperature | 302°F → 338°F |

| Tensile strength | 36,000 lbs → 42,000 lbs |

| Compressive strength | 30,000 lbs → 50,000 lbs |

| * | Dependent upon configuration |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.