Efficient and safe tubular cutting

An efficient and safe approach to drill pipe, liner, tubing and casing recovery operations without the need for explosives.

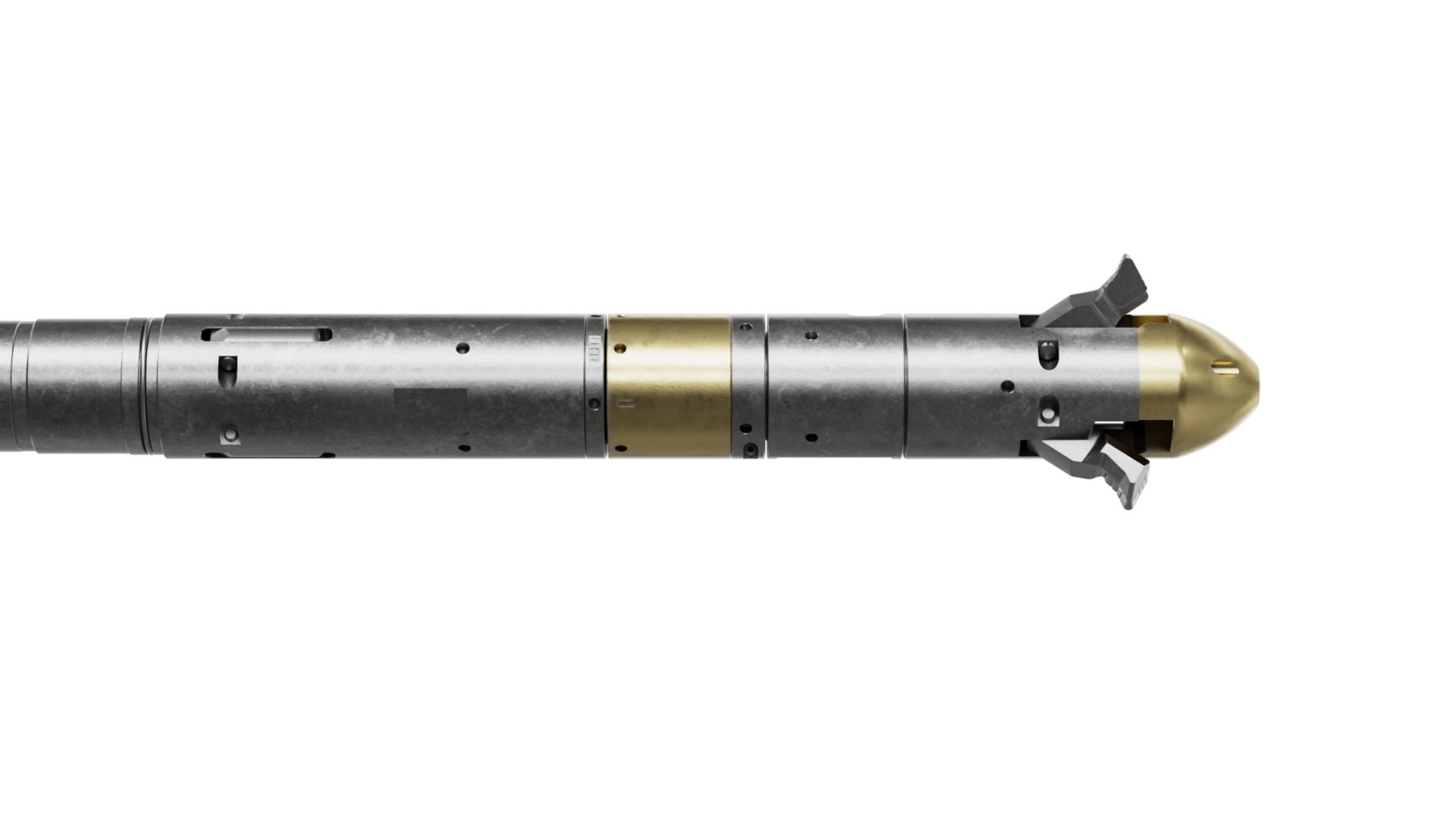

The Well Cutter uses a rotating head to remove pipe incrementally, which prevents the creation of shavings. Due to the smooth, bevelled surface it produces, a polishing trip with drill pipe may be eliminated for increased operational efficiency.

A key benefit of the Well Cutter is that it eliminates the use of explosives which can pose an operational risk, especially when simultaneous operations are being conducted. The transfer of explosives may also cause complex logistics and significant operational delays, making the Well Cutter an attractive alternative for pipe recovery operations. Conveyed on e-line for accurate depth control, the Well Cutter incorporates a ‘fail-safe’ mechanism that prevents the tool from getting stuck.

Featured case

In a deepwater Brazilian pre-salt P&A, Welltec deployed the Well Cutter 414 with a newly-developed ‘Tiger Claw’ cutting element to achieve a combined cut through 6-5/8” tubing and an Incoloy control line flatpack. The single-run operation delivered a clean, predictable cut that enabled smooth completion retrieval. The result: time saved, no explosives, and a first-of-its-kind field success.

The Well Cutter enables efficient and safe tubular cutting for pipe recovery or completion removal without the use of explosives. Utilizing a fast, grinding technique rather than a blade, the Well Cutter produces a smooth, polished surface.

This precludes the need for a polishing trip to dress the cut, resulting in significant rig time savings. It can be run slick, on e-line or equipped with a ‘no-go’ for a precise cut at depth. And it can be deployed independently or combined with the Well Tractor® for cuts in highly deviated or horizontal wells.

| Applications |

| Casing cutting |

| Drill pipe cutting |

| Liner cutting |

| Packer mandrels cutting |

| Control line cutting |

| Features |

| Works on pipe in tension or compression |

| Cuts L80, L80-13Cr, Super 13Cr, 25Cr, Inconel 718, P110, XD105, S135 |

| Modular and configurable |

| Compatible with all service providers |

| Accurate depth control |

| NACE compliant |

| Benefits |

| No explosives |

| Multiple cuts in the same run |

| Rigless cuts for batch work |

| Very small debris |

| No pipe dressing required |

| Monitoring of cutting operation with Welltec® SRO 1.0 |

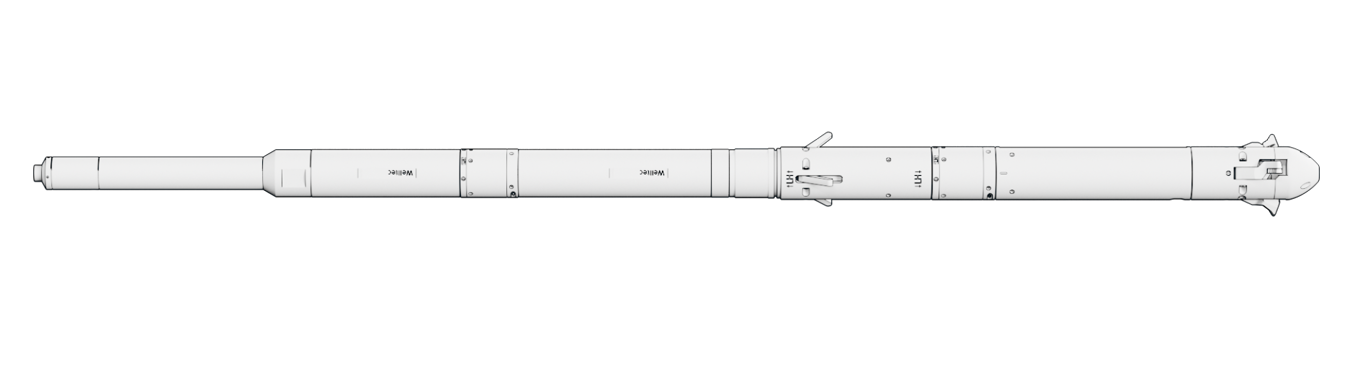

| Specification range* | |

| Tool OD | 2 3/8'' → 5 3/4'' |

| Length | 17.5 ft → 23.8 ft |

| Weight in air | 230 lbs → 897 lbs |

| Min. anchor ID | 2.85” → 5.85” |

| Max. pipe thickness | 0.375” → 1” |

| Pipe cutting range (OD) | 3.5” → 9.625” |

| Max. well temperature | 302°F → 350°F |

| Tensile strength | 36,000 lbs → 42,000 lbs |

| Compressive strength | 30,000 lbs → 50,000 lbs |

| * | Dependent on pipe material and well parameters |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.