High-speed precision milling

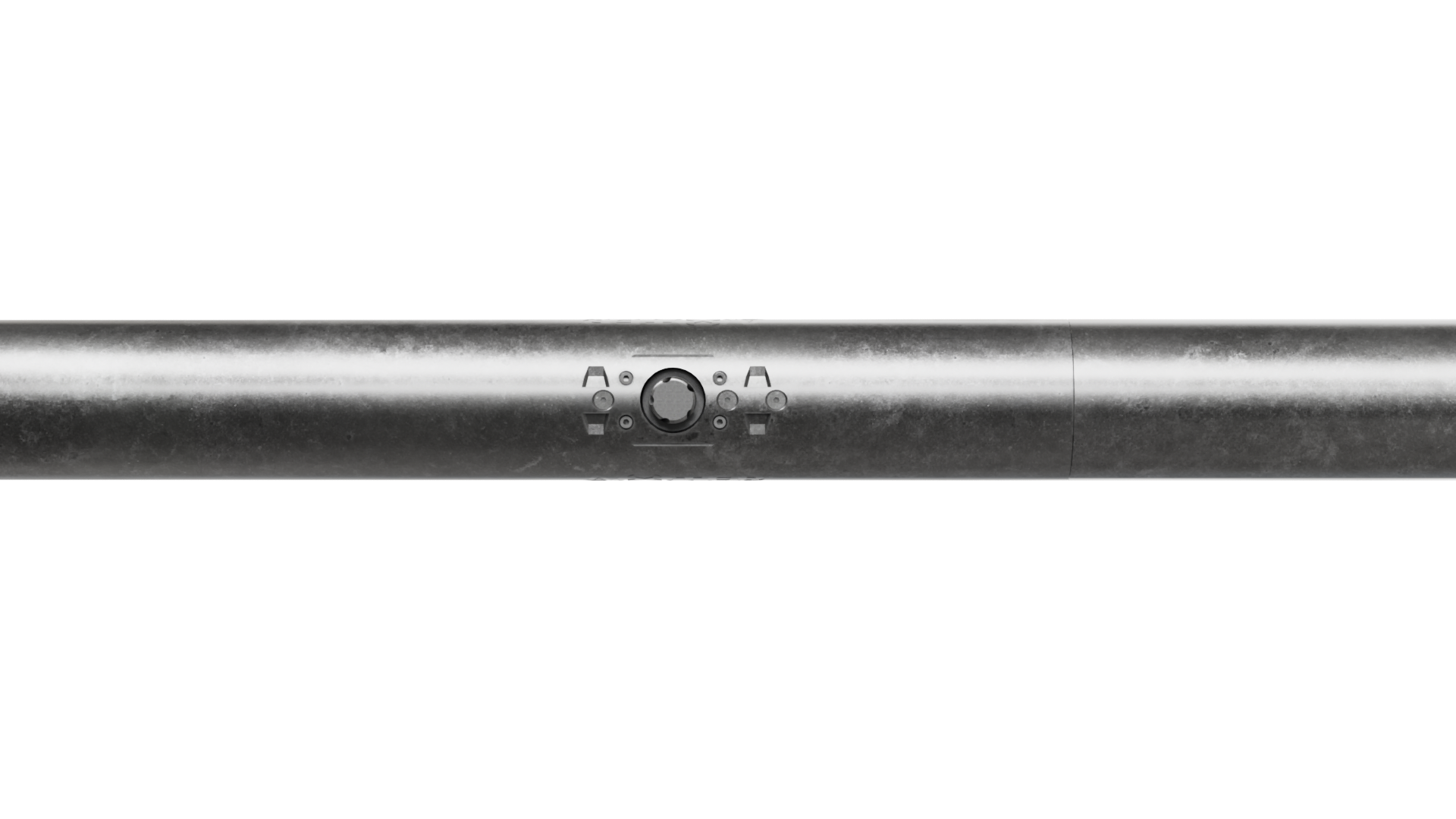

The Axter Lateral Miller is a programmable, high-speed precision milling tool designed for accurate and controlled downhole operations — so precise that you could write your name with it.

In plug and abandonment (P&A) and intervention scenarios, the miller creates a precise 200 mm (7.9”) window in production tubing, enabling controlled access to control lines without the need for full tubing removal. Its advanced multi-axis control ensures clean, targeted milling while preserving the integrity of surrounding components.

Capabilities and applications

This rigless, electro-mechanical milling solution streamlines P&A, intervention, and retrieval operations, delivering a cost-effective, high-precision approach to downhole milling.

| Applications |

| Plug and abandonment |

| Tubing cutting |

| Milling windows in tubing to allow for removal of control lines and fiber optic cables from the annulus |

| Creating slots/windows in wellbore tubulars |

| Milling holes in tubing to allow circulation |

| Milling restrictions to increase ID of nipples and other completion equipment |

| Milling weak points and profiles in the wellbore |

| Penetrate (cross boring) the hydraulic bore in TRSCSSV to allow for installation of a WRSCSSV |

| Cutting shunt tubes |

| Machining e.g. Nipple profiles |

| Features |

| Fully electro-mechanical tool |

| Pressure compensated design |

| Modular |

| Fully controllable RPM on bit |

| Fully controllable radial bit movement |

| Fail-safe mechanism that automatically retracts bit in case of power loss |

| Real-time surface readout (SRO) |

| Universal through wiring |

| Custom bits |

| Benefits |

| Enables accurate control of all parameters |

| Minimizes risk of tool flooding |

| Enables optimal RPM on different mill bit sizes and types |

| Ensures secure and accurate depth control |

| Prevents sticking in the event of toolstring communication loss during milling |

| Qualified up to Q-125 and high content Chrome tubing |

| Specification range* | |

| Length | 7.09 ft |

| Running OD nominal | 3.425" |

| Weight in air | 138.9 lbs |

| Tubing size | 4-1/2" |

| Maximum pipe thickness* | 0.6” |

| Maximum well pressure | 5,000 psi |

| Maximum well temperature** | 257°F |

| Tensile strength | 75,985 lbf |

| * | Dependent on pipe material and well parameters |

| ** | Dependent on configuration |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.