Welltec® Flow Valve - for inflow & injection management

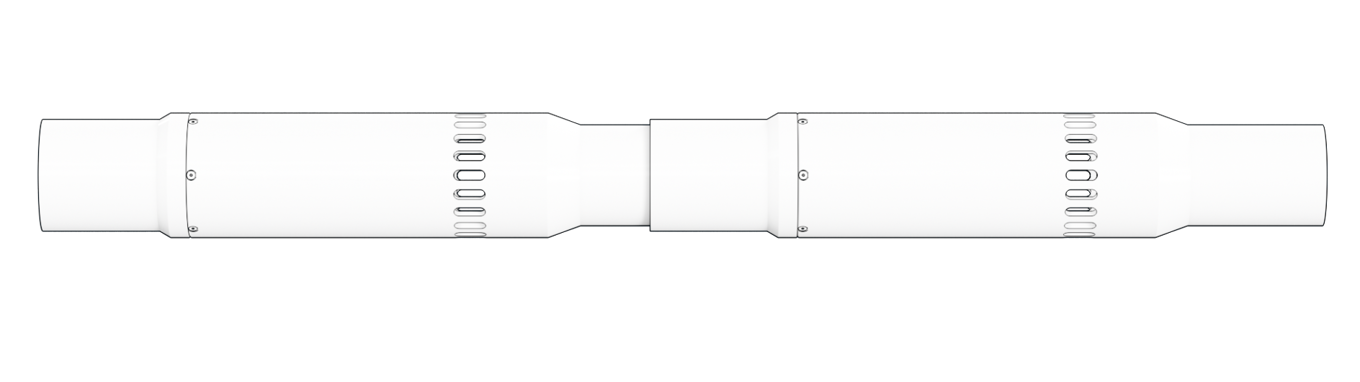

The Welltec Flow Valve is a full bore valve that can be used for both production and injection purposes within the lower completion, the rugged design enables rotation during liner deployment.

With specially designed inlets and sealing system, the WFV is qualified to open and close multiple times under differential pressure whilst maintaining flow, from both injection and production scenarios.

The full bore design makes it ideal for intervention-enabled completions and together with Welltec Annular Barrier providing high pressure zonal isolation, the WFV forms an integral part of the Flex-Well® completion.

Featured case

An operator in West Africa expanded the objectives of their first well in a new field from producing first gas to producing first gas and first oil. This change in goals...

Flow valves enabling isolation of water /gas breakthrough:

• Full bore design provides smooth flow area to minimize delta P loss

• Coatings to minimize scale deposition

• Robust seal design for manipulation under delta P

• High burst, collapse and torque capability

• All variants can be combined with sand screens

Deployment and operation:

• Shifting by Well Stroker actuation or drive by solution

• SRO confirmation of sleeve position

• Standard shifting profile

• Liner can be worked and rotated during deployment

Available sizes and specifications:

• From 2 7/8” WFV to 9 5/8” WFV*

• High temperature WFV available

• Materials fit to meet client specifications for pressure and tensile

• Product datasheet will be deliver for selected WFV

• Other sizes available upon request (lead times and feasibility to be determined)

| Applications |

| Applicable for wells in reservoirs with high potential for fractures. |

| Sequential zonal clean-up and production rotation |

| Manage bottom-up aquifer coning or gas cap cusping |

| Isolate later water/gas breakthrough in producers |

| Selective zonal injection / stimulation within injectors |

| Features |

| Flow area exceeding base pipe cross section |

| ON - OFF slot design |

| Low profile with minimum impact on ECD |

| Full bore design provides unrestricted flow path to minimize delta P loss |

| Coatings to minimize scale deposition |

| Coatings to minimize scale deposition |

| Robust seal design for manipulation under delta P |

| High burst, collapse and torque capability |

| All variants can be combined with sand screens |

| High temperature WFV available |

| Benefits |

| No limitation on the quantity of WFVs per main bore or lateral |

| Materials to match completion and environment |

| Enabler for cementless completions in combination with the Welltec Annular Barriers |

| Enables rotation during completion |

| Simple, reliable manipulation |

| Specifications | |

| Base pipe size | 3-1/2” → 9-5/8” |

| Max. burst pressure | 5,000 psi → 10,000 psi |

| Max. collapse pressure | 5,000 psi → 10,000 psi |

| Max. diff. unloading pressure | 1,500 psi → 2,000 psi |

| Max. OD | 4.57” → 9.8” |

| Min. ID | Full bore (as per base pipe) |

| Flow area range | Up to 110% of casing bore x-sectional area |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.