For cement replacement

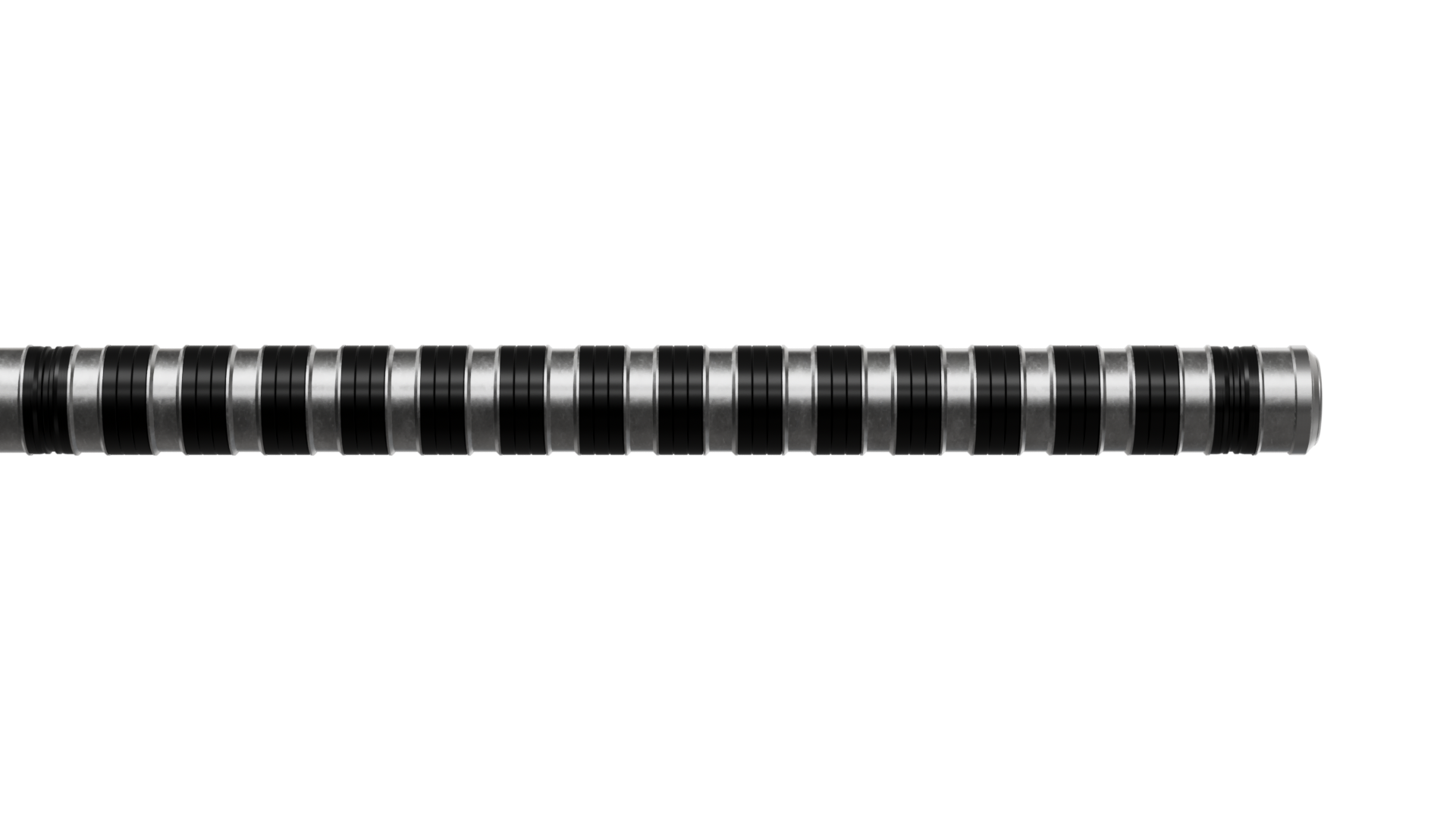

The Welltec Annular Isolation (WAI™) provides long length open hole zonal isolation, significantly reducing the free annulus space between the liner (casing) OD and the open hole ID. The removal of this annular space can be beneficial in highly layered reservoirs of varying permeability, where selective production, stimulation or water shut off is required.

The WAI metal expandable sleeve is hydraulically expanded quickly, under full surface control via the application of well bore pressure using the rig pumps. Sealing on the ID of the open hole is achieved via a series of compliant, elastomeric seals, backed up by full circumferential metal to rock contact fins that prevent seal extrusion under high differential pressure.

Featured case

An operator selected WAI for Cement Replacement after swell packer failures had caused high water cut and rapid watering-out. WAI deployment reduced losses from 750 bph to 15 bph in a lateral abandonment, followed by two more units straddling a fracture. The proven effectiveness led the client to designate WAI as its primary solution for isolation and abandonment.

At Welltec, we design and test the WAI range (Welltec Annular Isolation) in accordance to IS0 14310 V6 to V3 leak criteria. The WAI metal expandable sleeve is hydraulically expanded quickly, under full surface control via the application of well bore pressure using the rig pumps.

Sealing on the ID of the open hole is achieved via a series of compliant, elastomeric seals, backed up by full circumferential metal to rock contact fins that prevent seal extrusion under high differential pressure.

| Applications |

| Cement replacement across laminated & highly layered reservoir sections |

| Selective production |

| Selective stimulation |

| Water shut off |

| Overburden protection |

| WAI can be incorporated within open hole, cased hole and hostile environments |

| Features |

| Rugged, all welded, metallic construction |

| Expansion assurance |

| High expansion capability |

| Constant, high pressure ∆p over full expansion range |

| No premature expansion |

| NACE compliant |

| Slim OD allows for high rate circulation during deployment |

| Benefits |

| Rotatable during deployment enabling liner to TD in challenging environments |

| No Under-reaming / no extended shoe tracks |

| Pinpoint perforation for production / stimulation intervals |

| Isolates water production |

| Rapid set nature of WAI reduces time to production |

| High rate circulation capability |

| No CBL required across reservoir section |

| WAI can be expanded online or offline |

| Full bore – as per casing / tubing |

| Specifications | |

| Expansion range | 6” → 10.00” |

| Min. running OD | 5.75” → 8.18” |

| Base pipe range | 4 ½” → 7” |

| Max. working pressure | 5,000 psi → 8,500 psi |

| Constant element ΔP across expansion range | 2,000 psi → 4,000 psi |

| Max. temperature | 302°F / 150°C |

| Max. element length | 30 ft / 10 m |

| ID | Full bore (as per base pipe) |

| ISO14310 Standard | V3 |

| Standard elastomers & seals | HNBR / Aflas / FFKM / PTFE |

| Standard material | 316 / Alloy 28 |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.