Extended reach, cementless lower completions via rotatable, metal expandable packers

To increase net present value of their assets, extended reach horizontal reservoir sections are becoming critical to operators looking to increase well productivity and maximize their ROI.

Extended reach lower completion design creates significant concerns over the ability to execute a conventional cement or perforated liner well design due to the high inclination nature of the reservoir section. This is due to the required ability, across these heterogeneous formations, to isolate unwanted water or gas inflow by isolating and compartmentalizing the reservoir. To achieve this it is critical to design the well with reliable isolation between lower completion and open hole without the need for cement.

Featured case

In Brazil’s pre-salt, two 812WABs were deployed in an 8.5” open-hole completion to deliver zonal isolation across the water-oil contact. Built with FFKM seals for compatibility with calcium bromide (CaBr₂) in a high-pressure reservoir, the WABs expanded as planned and achieved effective annular isolation – reinforcing reliability and unlocking a broader campaign for the client.

Featured case 2

In the Middle East, six WABs were deployed in an open-hole horizontal well to establish zonal isolation and enable multi-zone control with remotely operated valves. Expanded at 4,000 psi under challenging conditions, the WABs delivered reliable, life-of-well sealing performance while preserving full-bore access — reducing both CAPEX and OPEX for the operator.

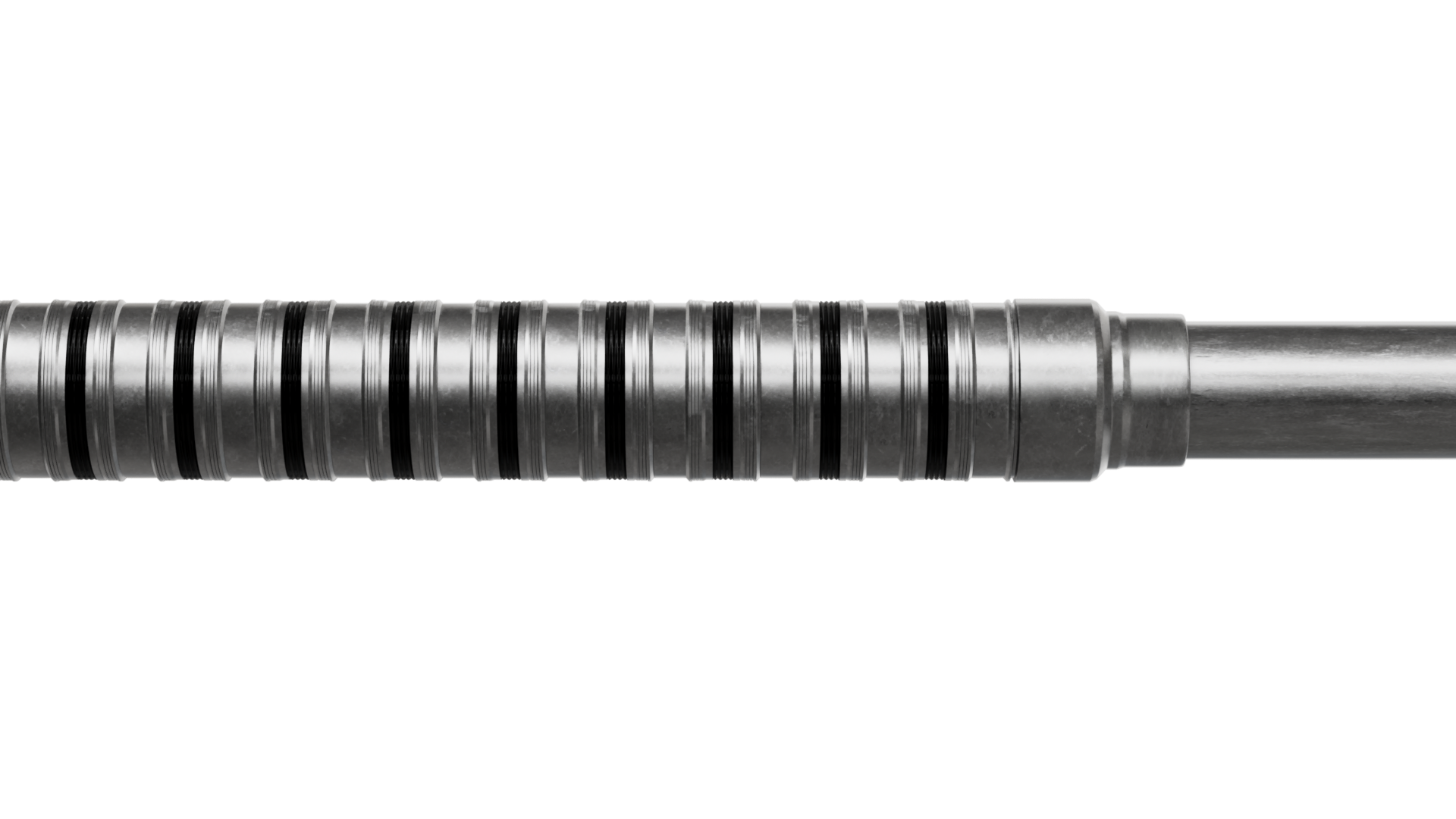

Our ISO 14310 rated, metal expandable WAB (Welltec Annular Barrier) for open hole zonal isolation, facilitates the ability to deploy ‘cementless’ extended reach, multi zone, horizontal, lower completions.

The WAB provides the on-demand, high pressure zonal isolation across varying borehole geometries unaffected by thermal changes in the wellbore, so often a problem in conventional open hole reservoir isolation.

| Applications |

| Zonal isolation within the reservoir |

| Zonal isolation between adjacent zones |

| Water / gas isolation |

| High pressure OH isolation for stimulation |

| Open hole, cased hole and hostile environments |

| Features |

| Rugged, all welded, metallic construction |

| Rotatable during deployment |

| Full bore – as per casing / tubing |

| Burst protection option available |

| Benefits |

| Slim OD allows for high rate circulation during deployment |

| High expansion capability |

| Constant, high pressure ∆p over full expansion range |

| Rapid set nature of WAB allows expedites time to production |

| Rapid set nature of WAB reduces time to production |

| No premature expansion |

| NACE compliant |

| Suitable for sour service |

| Specifications | |

| Expansion range | 5.75” → 10.00” |

| Min. running OD | 5.56” → 8.240” |

| Max. working pressure | 5,000 psi → 15,000 psi |

| Constant element ΔP across expansion range | 5,000 psi → >15,000 psi |

| Base pipe range | 4-1/2” → 7” |

| Standard element length | 7.2 ft |

| Temperature | 500°F |

| ISO14310 Standard | Up to V0 |

| ID | Full bore (as per base pipe) |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.