Future-proof wells for CAPEX effective P&A

Our WAB for Well Abandonment range, when incorporated within the cased hole as a life of well IS014310 V0* annular barrier or within the open hole, for life of well IS014310 V3 isolation, across the cap rock during well construction phase, will provide significant future value as the foundation for critical placement of P&A cement plug, significantly reducing the future complexity and CAPEX & OPEX cost associated with P&A.

Featured case

A national oil company used an 812WAB as an open-hole fault isolation plug to permanently seal a depleted reservoir during a gravel pack campaign. Its ability to rotate and circulate during deployment ensured reliable placement and the required isolation. The solution eliminated total losses, reduced CAPEX by 50%, and enabled routine gravel pack completion.

Featured case 2

In Norway, a 1214WAB provided a verifiable ISO 14310 V0 B-annulus barrier for an appraisal well, forming part of the permanent envelope and future P&A base. Combined with 812 and 6WAB horizontal liner hangers, the solution delivered gas-tight integrity, reduced risk, and CAPEX-efficient well construction and pre-emptive abandonment.

Globally, operators are faced with a large volume of wells, that require Plug & Abandonment, and they are now realising that these wells have not been constructed to accommodate Risk Free, CAPEX effective P&A. Couple this to ever stringent local regulations, operator P&A costs have significantly increased and can range from $4Mio for a single platform well and up to $11Mio for a single sub sea well.

This realisation has driven is a paradigm shift in drilling and well well construction methodology, to implement best practice for later well abandonment over the duration of the well life, during design, construction, production and ultimately abandonment. Cement alone is not a reliable barrier, and operators and now planning for the installation of multiple barriers and multi component barriers e.g. combine cement with mechanical barriers and resins to construct wells now, planning for the future.

To support this market shift, our WAB range, when incorporated within the cased hole for IS0 14310 V0 barrier or open hole, for IS0 14310 V3 isolation across the cap rock during well construction phase, will provide added future value as the foundation for placement of P& A cement plug, significantly reducing the future complexity and cost associated with P&A.

| Applications |

| IS0 14310 V0* cased hole SCP barrier |

| IS0 14310 V3* open hole SCP cement assurance |

| IS0 14310 V3* standalone open hole SCP isolation |

| Platform for 2nd stage cement |

| Open hole cross flow isolation |

| Open hole fault isolation plug |

| Liner or casing hanger |

| Future platform for cap rock P&A |

| Whip-stock placement for sidetrack |

| WAB can be incorporated within open hole, cased hole and hostile environments |

| *Leak rate criteria |

| Features |

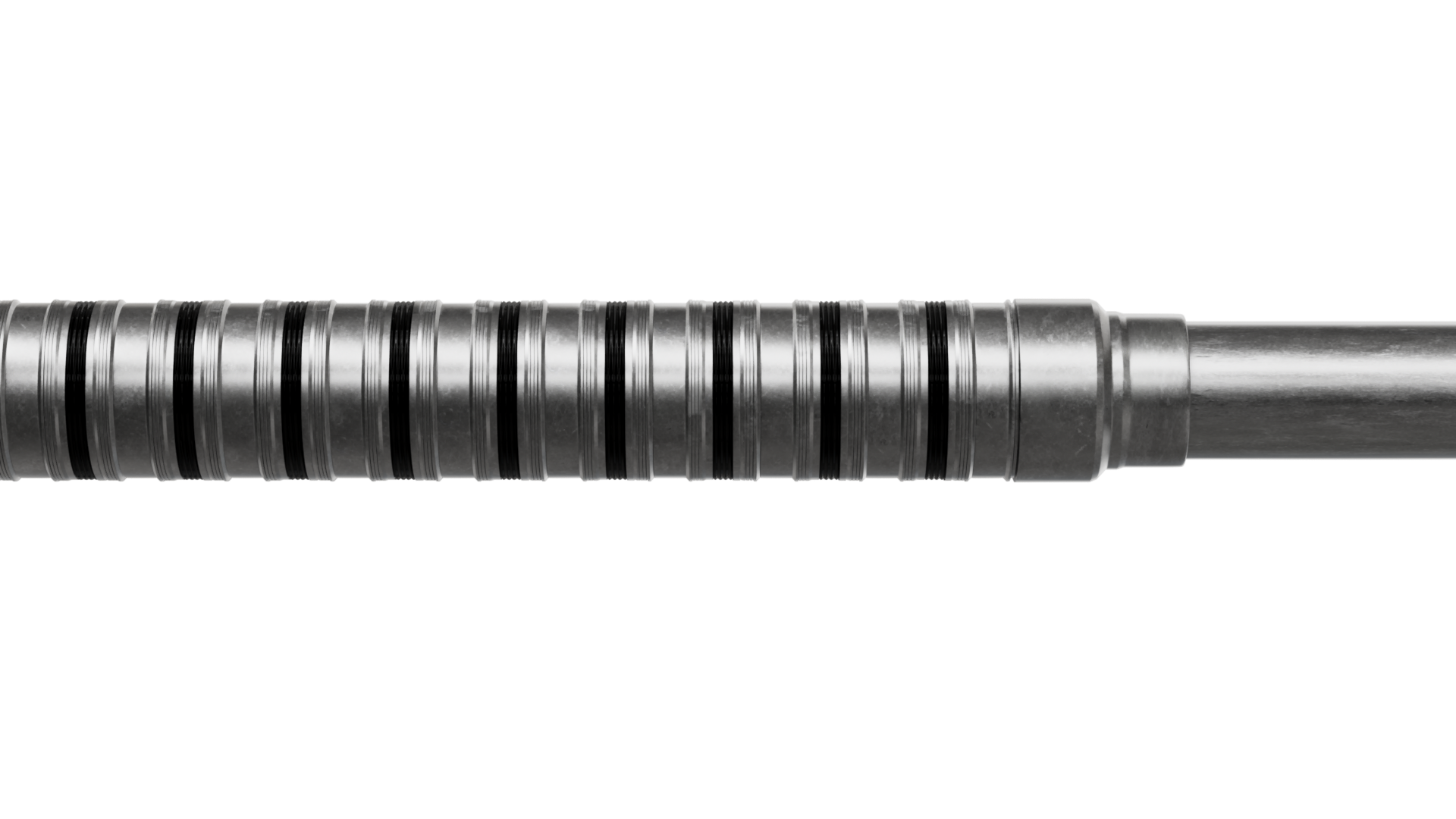

| Rugged, all welded, metallic construction |

| Rotatable during deployment & primary cementing |

| Casing Integrity post setting via Intergi-lock system |

| Flow back assurance for extreme environments via integri-lock system |

| Full bore ID – as per casing / tubing |

| Extensive portfolio to cover all open hole & cased hole requirements |

| Benefits |

| Slim OD allows for high rate circulation during deployment |

| High expansion capability |

| Constant, high pressure ∆p over full expansion range |

| Rapid set nature of WAB expedites time to next hole section |

| No premature expansion |

| High rate circulation capability |

| NACE compliant weld procedures |

| Specifications* | |

| Expansion range | 9.50” → 20.05” |

| Min. running OD | 9.00” → 17.00” |

| Max. working pressure | 4,000 psi → 8,000 psi |

| Constant element ΔP across expansion range | 4,000 psi → 8,000 psi |

| Base pipe range | 7-5/8” → 14” |

| Standard element length | 7.2 ft (2.2 m) |

| Temperature | 500°F |

| ISO14310 Standard | Up to V0 |

| ID | Full bore (as per base pipe) |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.