Autonomous inflow control solution

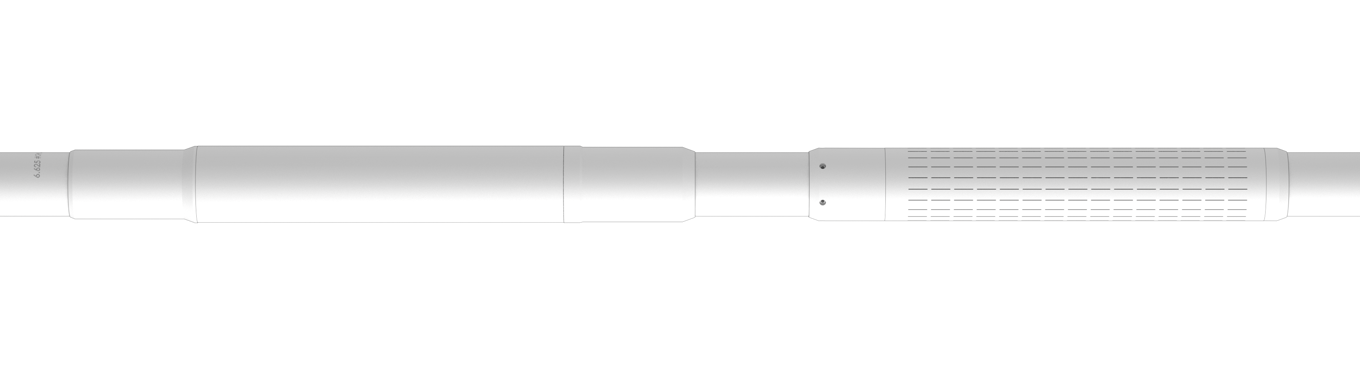

Density Activated Recovery (DAR™) is an autonomous completion technology designed to enhance recovery while simultaneously reducing water cut from multi-zone, horizontal completions.

Utilizing differences in fluid density to distinguish between wanted and unwanted fluids, DAR controls water production even in light-oil wells where oil and water have similar viscosities. It operates with minimal pressure drop and has a wide operational envelope.

Furthermore, its performance is insensitive to flow rate and reservoir conditions, which drastically reduces uncertainty and expands the application range for autonomous inflow control solutions.

Planned deployment

Two leading operators have selected Density Activated Recovery (DAR) technology for upcoming field trials aimed at autonomously reducing water cut in mature reservoirs. Developed by Innowell and supported by Welltec®, DAR selectively chokes high-water zones to lower water production and related emissions. The upcoming multi-well installations mark a major step toward sustainable, self-regulating inflow control.

Density Activated Recovery (DAR™) represents the next generation of autonomous inflow control technology. In compartmentalized horizontal wells, it locally restricts excessive inflow of unwanted fluids from the reservoir – such as water and/or gas. While water cut is an increasingly challenging aspect of production as reservoirs become more and more depleted, DAR technology works independent of viscosity, pressure, and flow rate to overcome variability.

By regulating overall production from zones with a high water cut rate, produced water is also significantly reduced. In turn, this minimizes the environmental challenges and costs associated with handling, processing, and safely disposing of dirty water.

| Applications |

| Horizontal oil wells with potential for excessive water and/ or gas production |

| Horizontal gas wells with potential for excessive water / condensate production |

| Features |

| Operates autonomously |

| Locally restricts inflow once phase fraction of unwanted fluid exceeds pre-defined value |

| Insensitive to reservoir pressure, productivity, and fluid viscosities |

| Single Phase (water or gas) and Dual Phase (water and gas) configuration available |

| Simple integration with conventional lower completion systems / sand screens |

| High-capacity injection capability without need for intervention |

| Allows washpipe-free installation |

| Benefits |

| Unrestricted oil production prior to water and/or gas breakthrough |

| Customizable choking efficiency for water and/or gas |

| Improved lift, frontloaded production profile, and increased ultimate recovery |

| Reduced need for reservoir pressure support initiatives and artificial lift |

| Reduced water and/or gas handling, treatment and reinjection |

| Reduced greenhouse gas emissions |

| Specifications | |

| Base pipe | 3-1/2” → 6-5/8” |

| Standard material | Matched with base pipe |

| Control line bypass | Yes |

| Size (*) | 5-3/4" and 8-1/2" |

| OD | 5.500 in (534 DAR) and 8.000 in (812 DAR) |

| ID | 2.992 in (534 DAR) and 4.252 in (812 DAR) |

| Assembly length (**) | ~ 59 in |

| Operating pressure | 10,000 psi (690 bar) |

| Differential pressure | 1,450 psi (100 bar) |

| Max. temperature | 150 ºC (302 ºF) |

| Service (***) | Standard |

| Well deviation (****) | 82º - 98º |

| Max. dogleg | 10º / 30 m |

| (*) 534 DAR assembly expected mid-2025 | |

| (**) Exact assembly length with be determined by the number of optional modules included and screen / filter integration method | |

| (***) Sour Service solution available upon request | |

| (****) DAR assembly for vertical well application to be qualified |

Talk to your local expert

At Welltec, our team of specialists is experienced in resolving the unique challenges of well drilling and operations across diverse terrain. Whatever your need, we can help you find a solution.