Case highlight

A water injector was experiencing issues with carbonate scale build-ups that led to decreased injectivity. KHA1-51 was completed in 2011 as one of the deepest injectors...

Well Miller®

For Scale Removal

Certain types of scale require a different type of approach, one more akin to milling than cleaning.

The Well Miller for Scale Removal transforms the power of the Well Miller into a clean-out application for those scale deposits which can’t be removed effectively with standard clean-out tools. A variety of bits can be applied with varying degrees of aggression. Full bore, core bore or wire bits can be applied for effective removal of stubborn scales.

A water injector was experiencing issues with carbonate scale build-ups that led to decreased injectivity. KHA1-51 was completed in 2011 as one of the deepest injectors...

The Well Miller for Scale Removal transforms the power of the Well Miller into cleaning solutions for removal of accumulations which can’t be removed effectively with brushing.

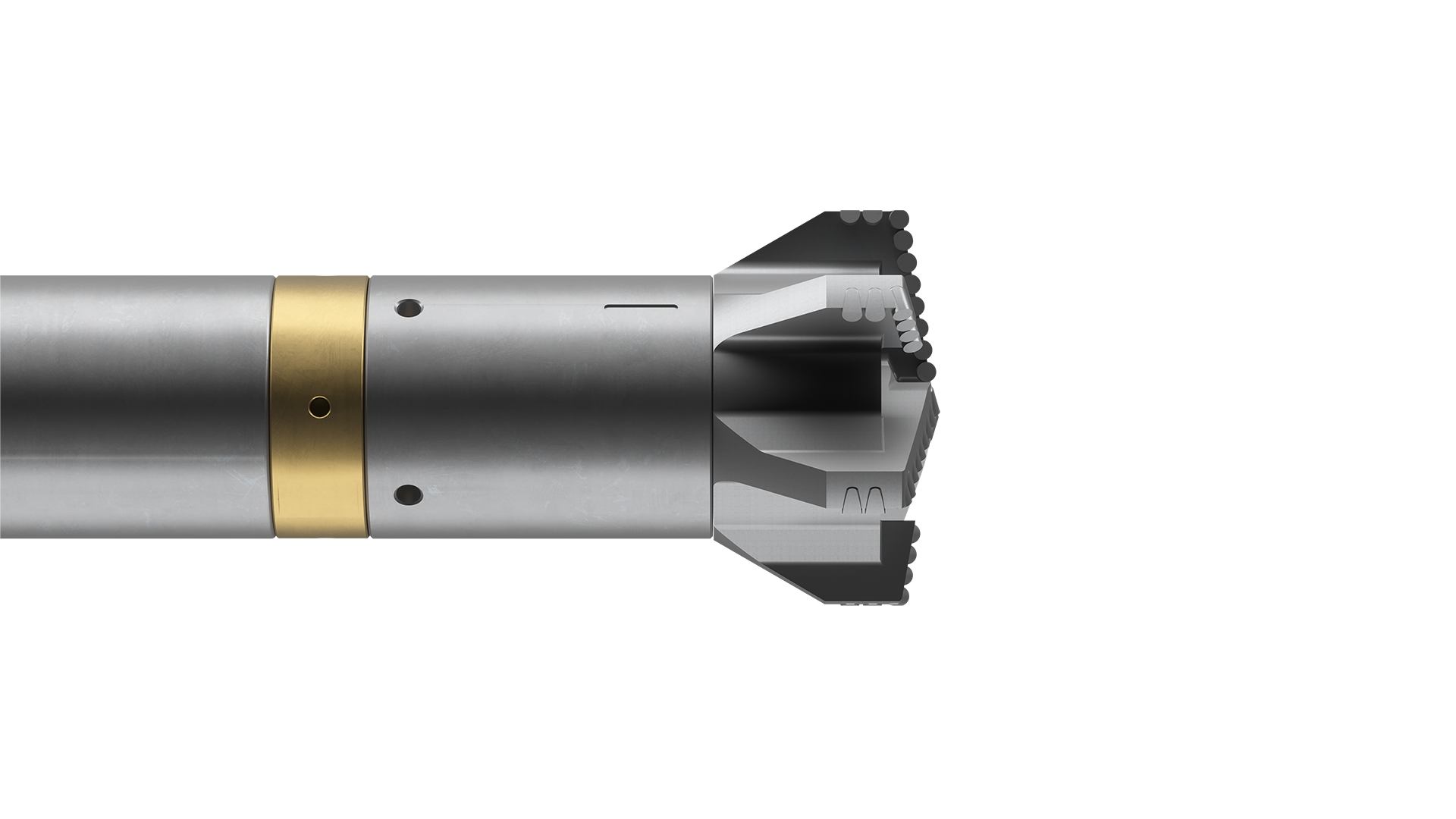

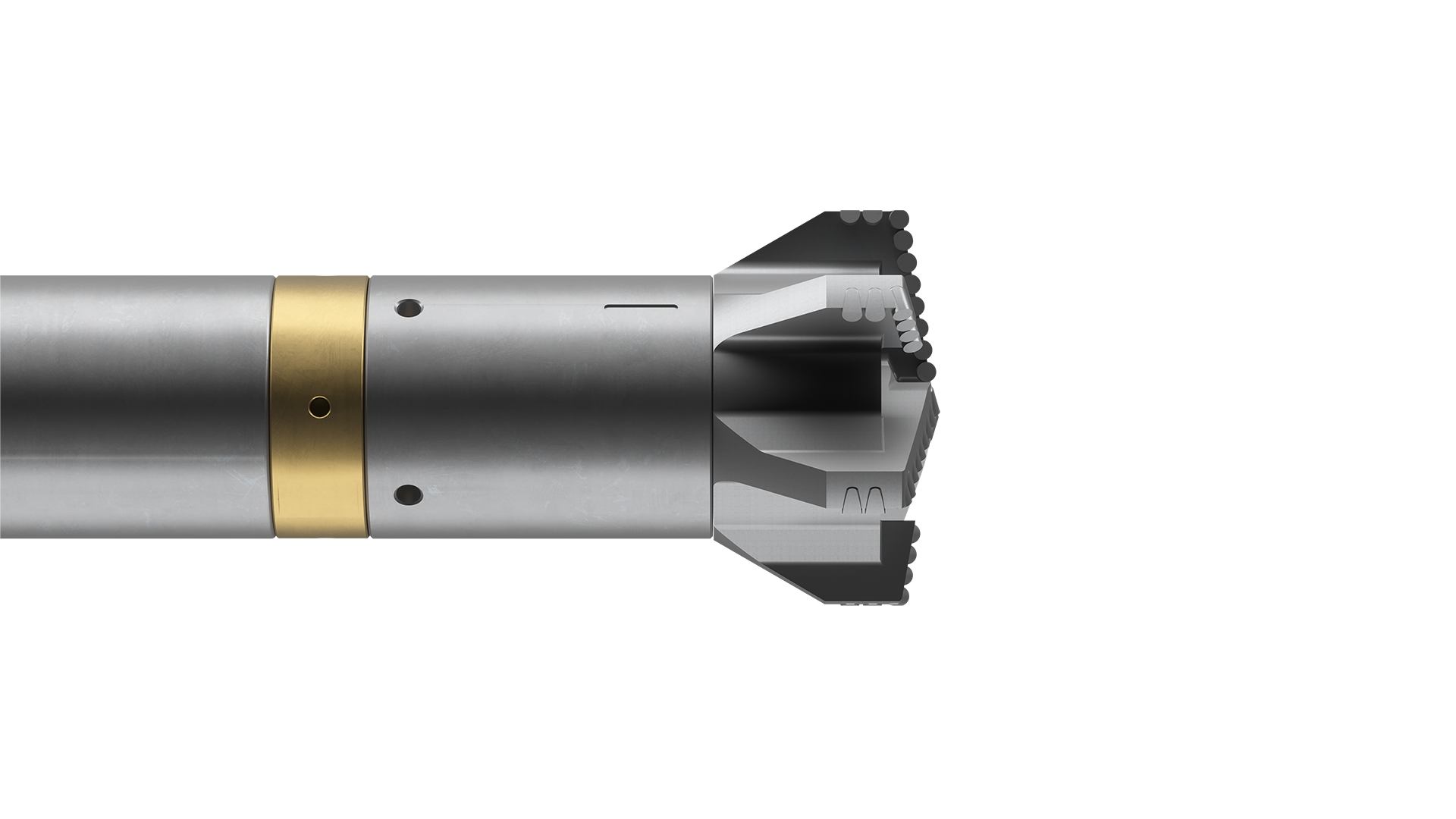

The full bore bit is ideal for attacking layers of scale that are severely reducing the ID and subsequently the production. It is designed to mill through substantial amounts of build-up and restore the tubular to full bore.

The scale core bit is designed for shaving scale sheathes from the inner walls with diamond tipped aggression. With a tighter tolerance to the ID, it is a perfect solution for removal of scale patches over long intervals.

The wire bit is developed specifically for milling scale that has settled on or inside valves within the wellbore. It is built to attack scale in irregular holes, depressions and upsets in the wellbore.

Scale milling with the Well Miller is run in combination with the Well Tractor® which applies the correct weight on bit and prevents reactive torque buildup on the e-line.

| Tool OD | 2 1/8” 3 1/2” |

|---|---|

| Length | 10 ft 12 ft |

| Weight in air | 70 lbs 95 lbs |

| Min. completion ID | 2.25” 3.6" |

| Max. well pressure | 20,000 psi 25,000 psi |

| Max. well temperature | 302°F 338°F |

| Tensile strength | 36,000 lbs 42,000 lbs |

| Compressive strength | 30,000 lbs 50,000 lbs |

| * | Dependent upon configuration |