Case highlight

Improper zonal isolation can cause production losses and lead to the requirement of additional workover activities throughout the life of a well...

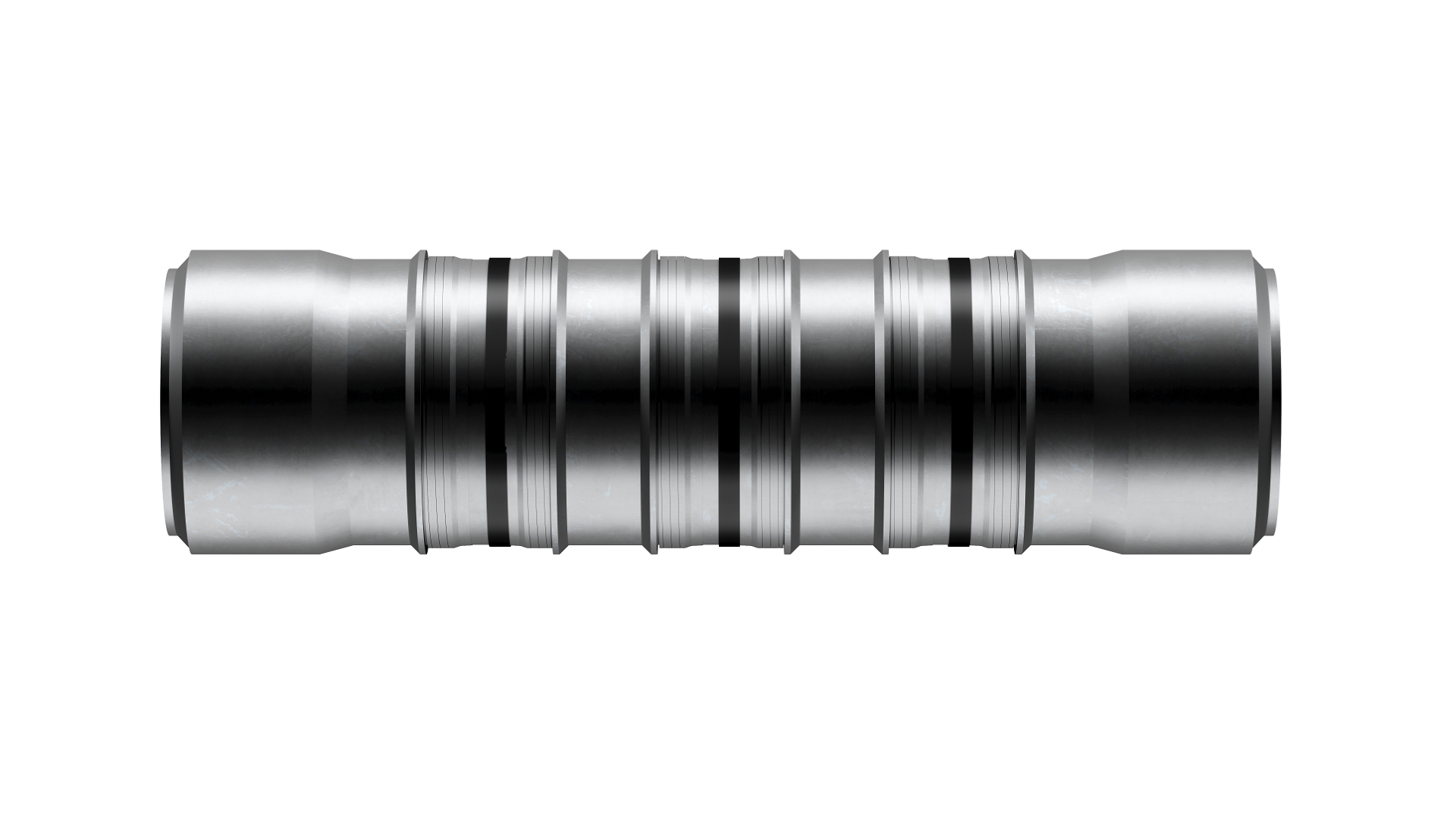

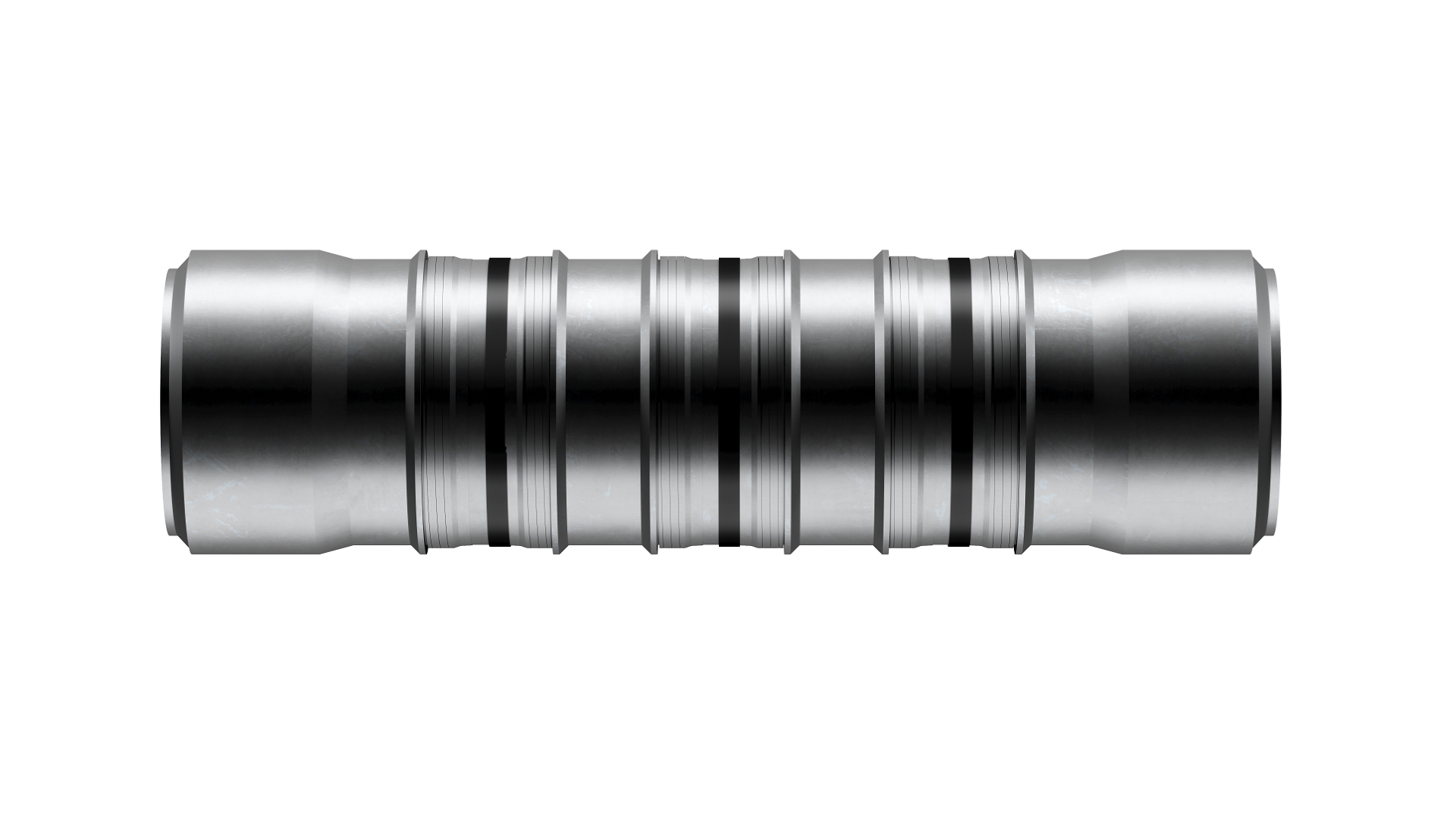

WLP - Welltec® Light Packer

For Zonal Isolation

The WLP (Welltec Light Packer) is our tiered offering to the zonal isolation and well construction & integrity markets, developed specifically for less hazardous environments & lower tertiary markets, that have historically incorporated legacy swellable technology as a means for isolation.

The WLP provides a number of the benefits of our flagship WAB (Welltec Annular Barrier), but incorporates design & construction efficiencies that facilitates a CAPEX effective technology for these, sometime marginal, applications.

Improper zonal isolation can cause production losses and lead to the requirement of additional workover activities throughout the life of a well...

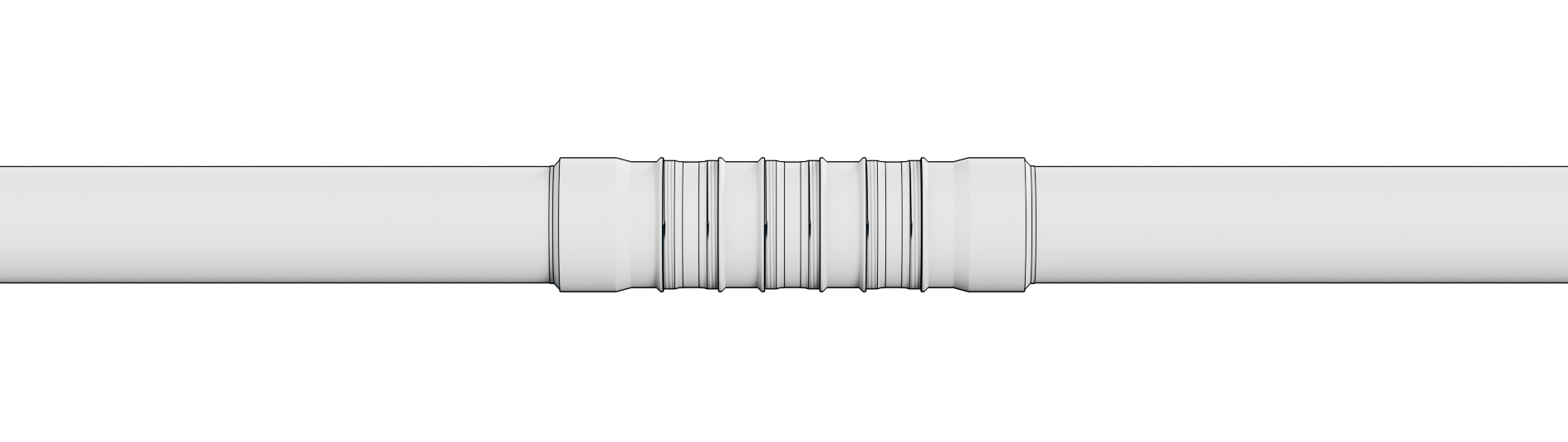

The Welltec Light Packer is a surface controlled, metal hydraulic expandable packer. It is mounted onto full bore liner/tubing/casing sealing off the annulus within a cased hole as well as open hole environment and forms part of the Flex-Well lower completion solution.

The WLP range offers a tiered version of the WAB (Welltec Annular Barrier) for the less demanding environments, delivering cost-effective performance across a range of operating conditions.

The WLP is more compact in sleeve length, therefore reducing overall sealing length and utilizes an optimized standard sleeve material, whilst providing consistency in open hole/cased hole seal design from the flagship WAB.

The WLP is a high grade, robust alternative to swellable technology for zonal isolation & cement assurance.

| Expansion range | 3.75" 15.00” |

|---|---|

| Min. running OD | 3.50” 11.62” |

| Max. internal pressure | 4,500 psi 8,000 psi |

| Constant element ΔP across expansion range | 1,500 psi 3,000 psi |

| Base-pipe range | 2-7/8” 9-5/8” |

| Standard element length | 1.3 ft |

| Max. temperature | 320°F |

| ISO14310 Standard | V6 |

| ID | Full bore (as per base pipe) |