Case highlight

Many wells that have well integrity and zonal isolation issues are due to failure of cement. Attempting to place cement and achieve full circumferential coverage...

WAI™ - Welltec® Annular Isolation

For cement replacement

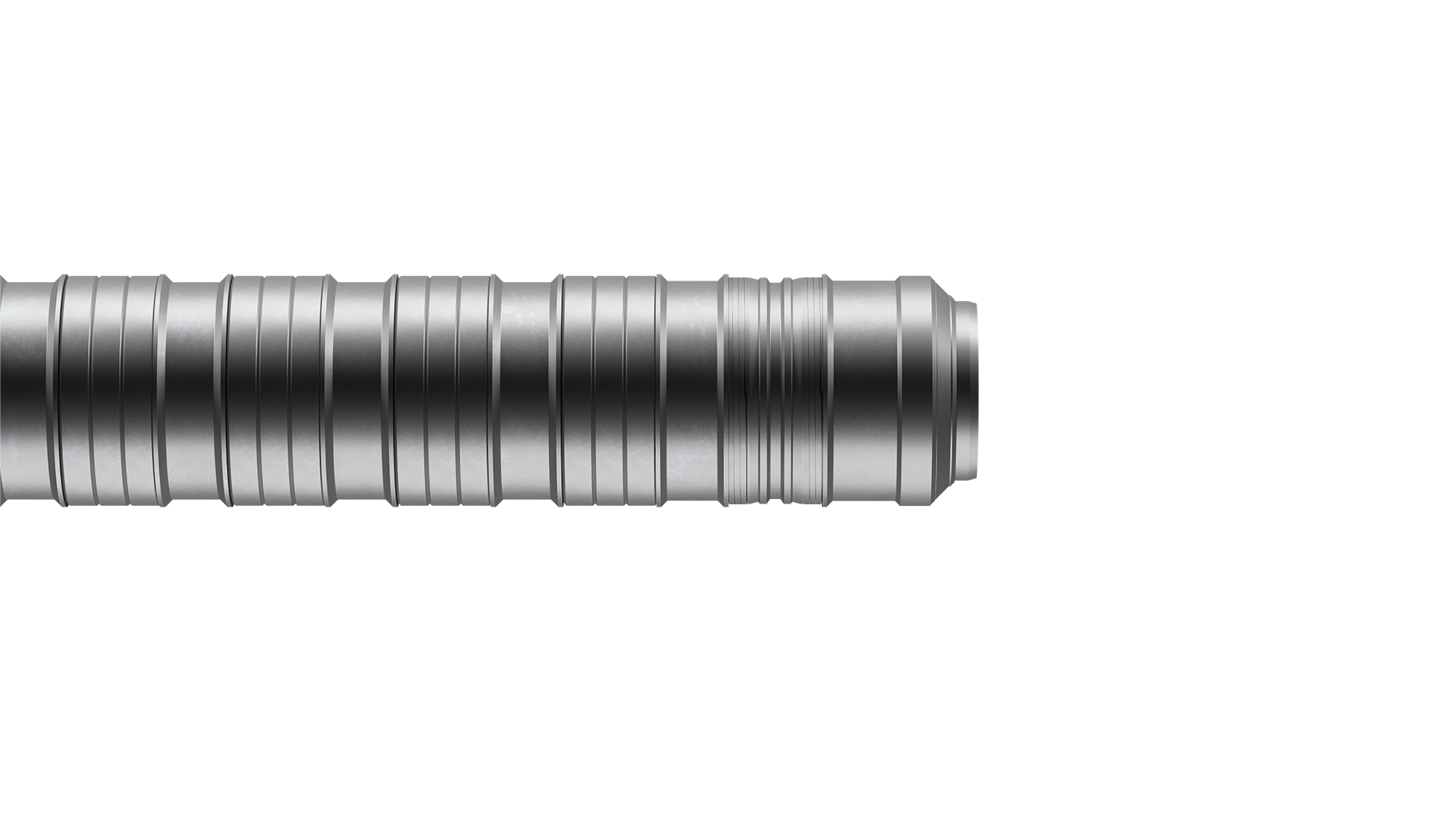

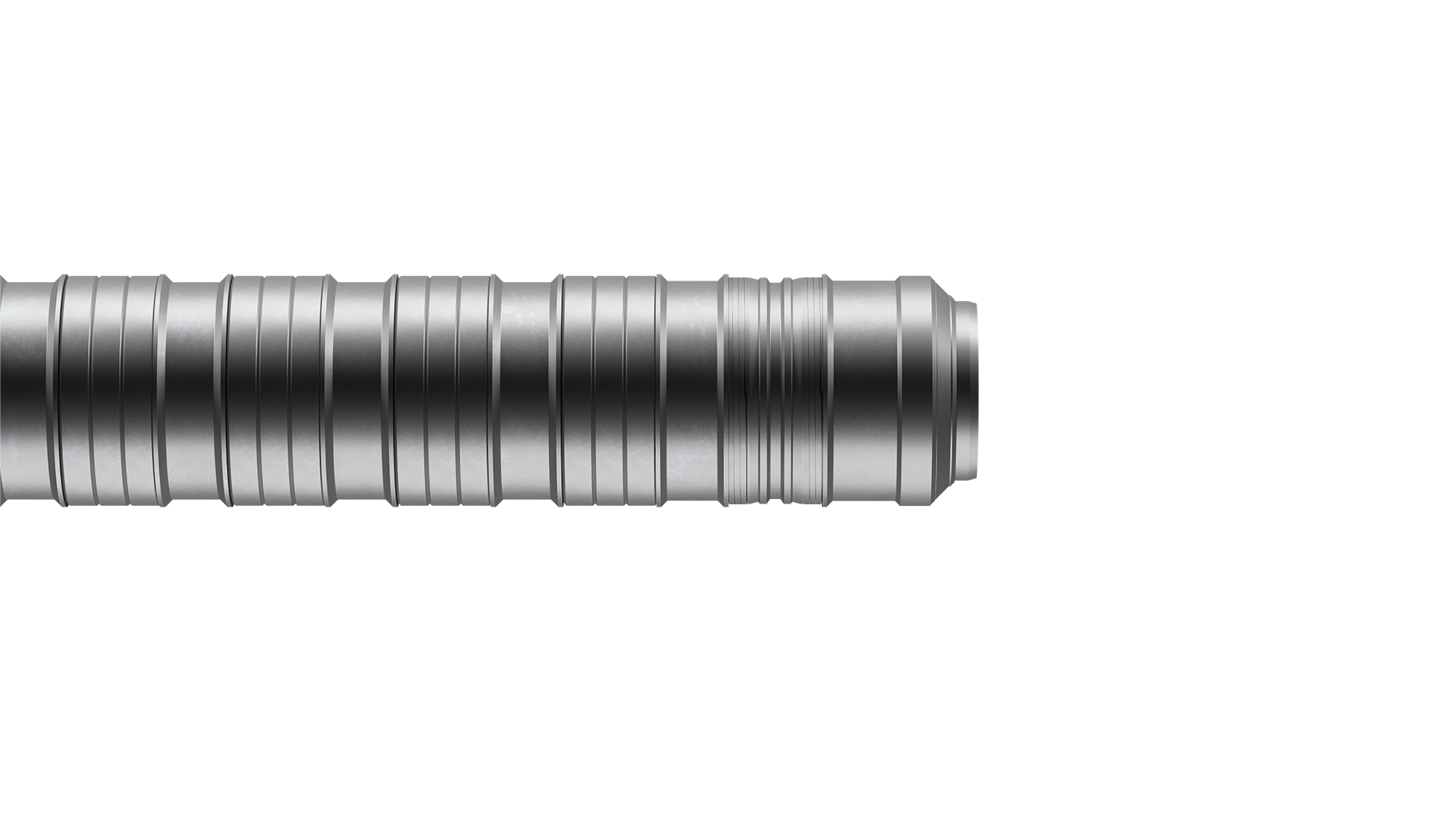

The Welltec Annular Isolation (WAI™) provides long length open hole zonal isolation, significantly reducing the free annulus space between the liner (casing) OD and the open hole ID. The removal of this annular space can be beneficial in highly layered reservoirs of varying permeability, where selective production, stimulation or water shut off is required.

The WAI metal expandable sleeve is hydraulically expanded quickly, under full surface control via the application of well bore pressure using the rig pumps. Sealing on the ID of the open hole is achieved via a series of compliant, elastomeric seals, backed up by full circumferential metal to rock contact fins that prevent seal extrusion under high differential pressure.

Many wells that have well integrity and zonal isolation issues are due to failure of cement. Attempting to place cement and achieve full circumferential coverage...

At Welltec, we design and test the WAI range (Welltec Annular Isolation) in accordance to IS0 14310 V6 to V3 leak criteria. The WAI metal expandable sleeve is hydraulically expanded quickly, under full surface control via the application of well bore pressure using the rig pumps.

Sealing on the ID of the open hole is achieved via a series of compliant, elastomeric seals, backed up by full circumferential metal to rock contact fins that prevent seal extrusion under high differential pressure.

| Expansion range | 6.00" 10.00” |

|---|---|

| Min. running OD | 5.75” 8.18” |

| Base pipe range | 4 ½” 7” |

| Max. internal pressure | 5,000 psi 8,500 psi |

| Constant element ΔP across expansion range | 2,000 psi 4,000 psi |

| Max. temperature | 302°F / 150°C |

| Max. element length | 30 ft / 10 m |

| ID | Full bore (as per base pipe) |

| ISO14310 Standard | V3 |

| Standard elastomers & seals | HNBR / Aflas / FFKM / PTFE |

| Standard material | 316 / Alloy 28 |