Cutting 512 tubing on deep water drill ship with pipe in 30,000 lbs compression

- Well type Dual zone producer, cased hole

- Max. pressure 2,277 psi @ 6,480 ft

- Max. temperature 176°F @ 6,480 ft

- Max. deviation 45°

- Max. rig up height 33 ft

Background

A well offshore Nigeria was drilled and completed in July 2013. But due to regulations the operator was required to re-complete the well as a dual producer which entailed pulling the upper completion. The operator considered cutting the main packer but was concerned about the serious problems a partial cut could lead to. Therefore they elected to cut the tubing above the packer instead.

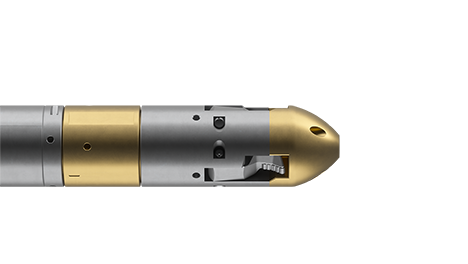

The program called for cutting the 5-1/2” 20#, 13 CR pipe in order to retrieve the tubing. A cutting tool was mobilized, but given the excessive rig time forecast to put the pipe in tension for that tool, they were interested in alternatives. The Well Cutter® offered the ability to cut under compression and did not need to locate in the selective nipple below the packer, providing a much more agile and time saving option.

Operation

The intervention was performed from a drill ship with a limited rig-up height of only 33 ft (10m). At just 17.5 ft the 3 1/8” Well Cutter therefore constituted the ideal solution for the operator. The original plan was to cut the packer mandrel. If that did not work then a tubing cut was the alternative. Both cuts were planned with the Well Cutter for operational efficiency. Later, for ease of operation, it was decided that cutting the tubing would be sufficient for the re-completion requirement.

This would avoid the need to locate the string in the selective nipple below the packer. During operations the Well Cutter blades were positioned in the tubing cutting zone above the packer at 6,480 ft (1,975m). Once correlation was duly confirmed the cutting operation commenced and a flawless cut was produced in ~ 4 ½ hours.

Achievements

The Well Cutter saved two days of rig time compared to the other cutting tool because of its ability to cut in compression. This saved the operator from having to remove the subsea tree in order for the tubing to be put in tension by a rig.

Being able to cut under compression and not needing to locate in the selective nipple below the packer in order to position the Well Cutter on depth secured a very time efficient operation.

The Well Cutter saved two days of rig time compared to the other cutting tool because of its ability to cut in compression.